In today's intricate and competitive business landscape, organizations must leverage robust strategies and exhibit agility to thrive. The effective implementation of these strategies is pivotal and fundamentally anchored in human capital,... more

Alaşım, iki veya daha fazla metalin belirli oranlarda eritilerek oluşturduğu homojen karışımdır.

An alloy is a homogeneous mixture formed by melting two or more metals in specific proportions

An alloy is a homogeneous mixture formed by melting two or more metals in specific proportions

Some treatments of metals and alloys in electrolyte give opportunities to modify their surfaces. The surface layers after electrical discharge treatment in electrolyte have different structure in comparison with the metal matrix,... more

Additive manufacturing has the potential to make a longstanding impact on the manufacturing world and is a core element of the Fourth Industrial Revolution. Additive manufacturing signifies a new disruptive path on how we will produce... more

Applications of coated surface are swiftly increasing in present industrial context. Recently, the electro-discharge route is being explored for surface modification in terms of alloying and layer deposition. Electro-discharge machining... more

As NASA, the Department of Defense and the aerospace industry in general strive to develop capabilities to explore near-Earth, Cis-lunar and deep space, the need to create more cost effective techniques of propulsion system design,... more

Nowadays, in order for small and medium scale enterprises to excel in performance, it is necessary to have congruency among the manufacturing functions and the operational priorities. In this paper a model is presented to know the... more

A tecnologia tem se mostrado uma vantagem competitiva em nossos ambientes industriais. Desde atividades básicas como plantio e agropecuária até a transformação e desenvolvimento do produto acabado, ela pode ser empregada a fim que agregue... more

To optimize the welding process of the upper frame of the hydropower unit, a thermal elastic-plastic (TEP) finite element model of the typical T-joint of the upper frame was established, and the effectiveness and accuracy of the model... more

Currently, the development of information technology in all fields is very rapid, including in the manufacturing sector, thus making the social environment of manufacturing change a lot. Traditional manufacturing research focuses on... more

Currently, the development of information technology in all fields is very rapid, including in the manufacturing sector, thus making the social environment of manufacturing change a lot. Traditional manufacturing research focuses on... more

Welding is a manufacturing process, which uses heat or pressure to form a homogeneous weld when joining homogeneous or heterogeneous metal materials or thermoplastics. The last decade has been characterized by the intensive development of... more

En el trabajo se trata de identificar cuáles son las principales variables que intervienen en el desarrollo de Ciencia, Tecnología e Innovación (CTI) de manera de poder utilizar ese conocimiento para hacer propuestas que guíen la... more

Distributed recycling and additive manufacturing (DRAM) offers a path to a circular economy. • Custom colors can increase value of DRAM polymers. optimal method, assessment criteria include the application of root mean square (RMS) and... more

In the present study, the nickel aluminide NiAl-based composite, reinforced with yttrium oxide Y2O3 with addition of titanium, was prepared by sintering at 1350 ° C for one and a half hours under an atmosphere of argon gas. Experimental... more

The intersection of data engineering and artificial intelligence (AI) has revolutionized modern industries using scalable, efficient, and intelligent automation. AI applications rely on robust data engineering frameworks for data... more

Effects of Process Parameters onMachining Time in Wire Electrical Discharge Machining of 9CrSi Steel

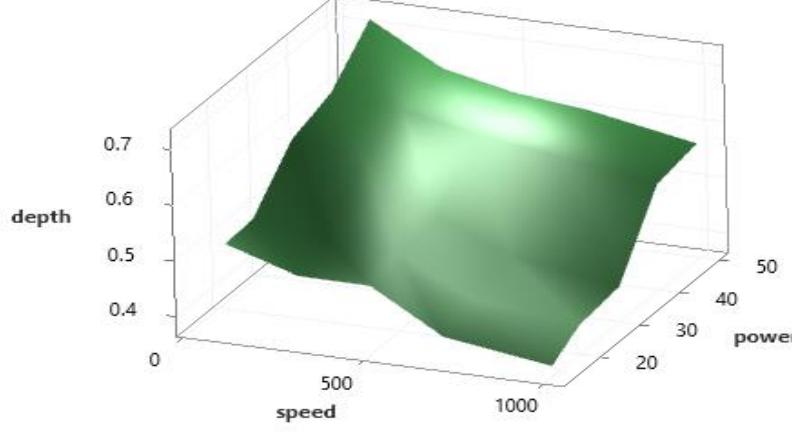

This paper introduces a study on the influence of process parameters on the machining time in Wire Electrical Discharge Machining of 9CrSi tool steel. In this study, a total of experiments were performed based on full factorial design and... more

To increase the process stability and improve the product quality in the sheet hydroforming with die process, it is crucial for identifying and analyzing the dependence of forming pressure on process parameters. The effects of process... more

This study investigates the interconnection between 3D printing and artificial intelligence. The accelerated evolution of 3D printing and AI technologies presents a unique opportunity to enhance digital design and manufacturing processes.... more

This paper presents the results of the study of plates with a combined "steel basetitanium, oxide coating" structure, which was obtained by resistive welding and strengthening induction heat treatment. The data of measurements of hardness... more

Among the family of liquid composite molding techniques, bladder-assisted resin transfer molding (BARTM) enables efficient manufacturing of hollow composite parts based on tubular reinforcing textiles. However, resin injection under... more

The Russian MC-21 commercial aircraft, developed by Irkut Corporation under the United Aircraft Corporation (UAC), represents a significant advancement in Russia's aerospace industry. This paper explores the features of the MC-21, its... more

The performance of the WEDM machining process mainly depends upon the suitable selection of the appropriate machining variables. Optimization is one of the techniques used in manufacturing sectors to arrive for the best manufacturing... more

This paper explores the transformative role of Internet of Things (IoT) technologies in revolutionizing urban waste management and its integration into sustainable urban planning. IoT-enabled systems provide real-time data monitoring and... more

Manufuture developed the Vision 2020, the Strategic Research Agenda and Road Maps as basics for the European Research in FP8. The vision was mainly influenced by the challenges toward competition and sustainability by transformation fr om... more

The paper shows the concept of Serbian Industry 4.0 Model based on cyber-physical manufacturing metrology model (CPM 3 ) and an integrated approach to manufacturing quality. The paper presents two directions of research: Virtual... more

A chasm is growing between the advanced technologies available for improving manufacturing operations and those effectively used in practice. The vision of Industry 4.0 is to mobilize industry to seek out these possibilities for... more

The development of Additive Manufacturing (AM) in the construction industry has become an innovative solution for sustainable built environment. Many researches are undertaken globally to elucidate the significance of additive... more

Increasing global competition has evolved a manufacturing environment which gleans vast product variety, reduced manufacturing lead times, increased quality standards and competitive costs. Simultaneously, with a rising trend toward... more

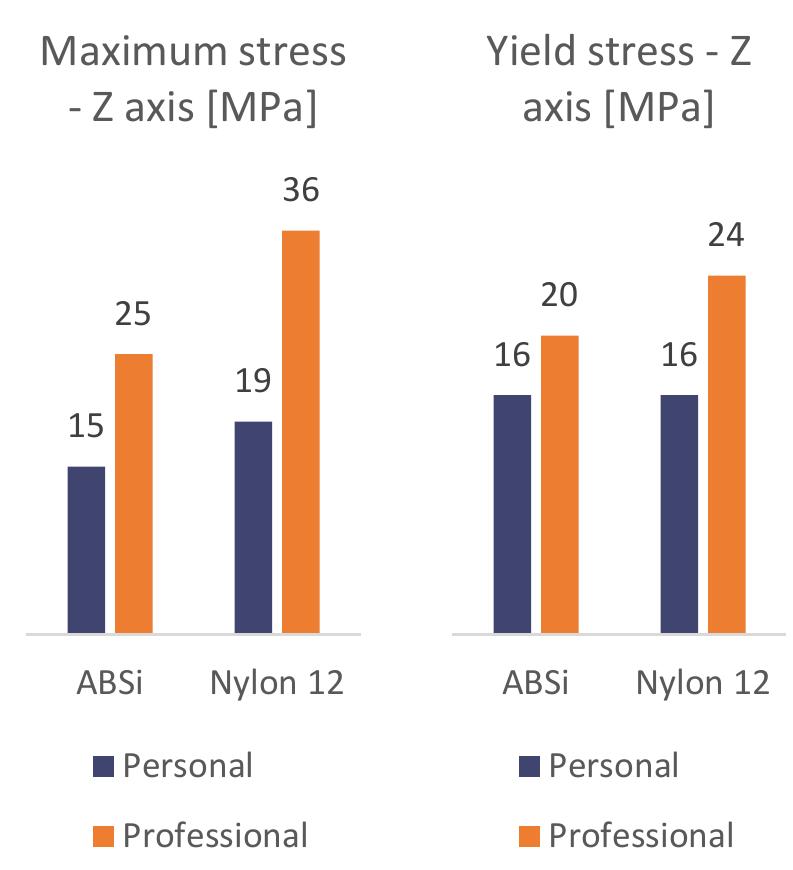

As 3D printing continues to grow as a viable manufacturing process, quantification of the processing options and parameters will allow for better design and modeling of printed parts, or at least to clearly understand the trade-offs... more

Generative manufacturing technologies are gaining more and more of importance as key enabling technologies in future manufacturing, especially when a flexible scalable manufacturing of small medium series of customized parts is required.... more

At present, sheet metal forming is gaining importance in the manufacturing sector and this process is essentially used to produce various engineering components having applications in railway cars, automobile bodies, construction, farm... more

In this work we evaluate the state of the semiconductor manufacturing industry and its challenges and trends. Future trends in the industry are analyzed from three perspectives: the evolution of Industry 4.0, the advances in semiconductor... more

This paper introduces a novel 4D printing approach for dynamic displays, using thermochromic-PLA composites embedded with FeCrAl wires activated by Joule heating. Previous studies struggled with high energy consumption, heat bleed, and... more

Spark-assisted chemical engraving (SACE) is a non-traditional micro-machining technology based on electrochemical discharge phenomena. In SACE gravity-feed micro-drilling, various parameters including the thermal properties of the tool... more

This study was aimed to investigate the weld microstructure and mechanical properties of as received and cryorolled Al 5083 alloy using friction stir welding (FSW). The comparison of the weld joint and mechanical properties of as received... more

This study provides a systematic review of the challenges and solutions in electric vehicle (EV) manufacturing, addressing key areas such as technological advancements, workforce readiness, supply chain optimization, sustainability... more

Wire Electrical Discharge Machining (WEDM) is one of the important non-traditional machining processes. The Wire Electrical Discharge Machining plays an important role in manufacturing sectors especially industries like aerospace,... more

The fourth industrial revolution brought a paradigm shift in the present manufacturing system and its supply chain management (SCM). The evolution of Industry 4.0 (I4.0) brought several disruptive technologies like cloud computing (CC),... more

Advanced Manufacturing Technologies (AMTs) have been helping manufacturing companies in the 21st Century to successfully manage the unpredictable, high-frequency market changes driven by global competition. However, despite the... more

The Role of Productivity Improvement Tools and Techniques in the Textile Sector during Manufacturing

Globally, the manufacturing industries have incredible contribution in the global economic growth and it has wide recognition in the area of poverty alleviation. The manufacturing sector is also considered as one of the significant... more

The Material Removal Rate (MRR) is very influencer factor in electrical discharge machining (EDM). In this work, the effect of EDM parameters such as current (10, 20 & 30A), pulse on time (50, 60 & 70 μs) and pulse off time (35, 45 & 55... more

Micro-EDM is one of an important process in machining holes which is used in wide applications to fabricate medical devices and small dies.20 samples were run by using CNC EDM machine was used for machining of conducting materials such as... more

Businesses achieve more industrial performance by integrating vertical and horizontal production processes and product linkage in Industry 4.0, at the beginning of the Industrial phase. To guarantee a sustainable progression of human... more

The present paper investigates the effects of fiber content and alkali treatment on impact property of coir fibers reinforced polyester resin composites which are partially biodegradable. The coir fibers were collected from the foliage of... more

This paper presents a literature review of Advanced Manufacturing Technology (AMT) based on a source bank of about 730 AMT publications, software and institutions. After introducing AMT briefly, the study focuses on AMT resources, and... more

Laser Engineered Net Shaping (LENS ™ ) was used to produce a compositionally graded Ti-xMo (0 ≤ x ≤ 12 wt %) specimen and nine Ti-15Mo (fixed composition) specimens at different energy densities to understand the... more

Laser machining plays a vital role in the manufacturing industry in producing innovative products and creating designs that were impossible by the traditional manufacturing process. Due to its consistency in achieving rapid cutting speed,... more

Manufacturing process constraints and design complexities are the main challenges that face the aftermarket automotive industry. For that reason, recently, selective laser melting (SLM) is being recognised as a viable approach in the... more

Challenges caused by design complexities during the design stages of a product must be coordinated and overcome by the selection of a suitable manufacturing approach. Additive manufacturing (AM) is capable of fabricating complex shapes,... more