Electrical Vehicle Design and Modeling

…

479 pages

1 file

Sign up for access to the world's latest research

Abstract

Early version, also known as pre-print Link to publication from Aalborg University Citation for published version (APA): Schaltz, E. (2011). Electrical Vehicle Design and Modeling. In S. Soylu (Ed.), Electric Vehicles -Modelling and Simulations (1 ed., pp. 1-24). Croatia: INTECH.

Figures (424)

![The relationship between the switching variable vector [a, b, c]t and the line-to-line output

voltage vector [Vab Vbc Vca]' and the phase (line-to-neutral) output voltage vector [Va Vb

Vc]t are given by the following relationships, where a, b, c are the orders of 51, S3, S5

respectively.

The structure of a typical three-phase VSI is shown in figure 6. As shown below, Va, Vb and

Vc are the output voltages of the inverter. S1 through S6 are the six power transistors IGBT

that shape the output, which are controlled by a, a’, b, b’, c and c’. When an upper transistor

is switched on (i.e., when a, b or c are 1), the corresponding lower transistor is switched off

(i.e., the corresponding a’, b’ or c’ is 0). The on and off states of the upper transistors, S1, Ss

and Ss, or equivalently, the state of a, b and c, are sufficient to evaluate the output voltage.](https://figures.academia-assets.com/55507705/figure_021.jpg)

![A hybrid electric vehicle is distinguee from a standard ICE driven by four different parts: a)

a device to store a large amount of electrical energy, b) an electrical machine to convert

electrical power into mechanical torque on the wheels, c) a modified ICE adapted to hybrid

electric use, d) a transmission system between the two different propulsion techniques.

Figure 1 shows the possible subsystems of a hybrid vehicle configuration [Chan, 2002],

[Ehsani, 2005]](https://figures.academia-assets.com/55507705/figure_030.jpg)

![The architecture of a hybrid vehicle is defined as the connection between the components

of the energy flow routes and control ports. Hybrid electric vehicles were classified into

two basic types: series and parallel. But presently HEVs are classified into four kinds:

series hybrid, parallel hybrid, series-parallel hybrid and complex . The primary power

source (steady power source) is made up of fuel tank and ICE and battery-electric motor

is taken as secondary source (dynamic power source).

A series hybrid drive train uses two power sources which feeds a single powerplant

‘electric motor) that propels the vehicle. In Figure 2 is shown a series hybrid electric

drive train where: fuel tank is an unidirectional energy source and the ICE coupled to an

electric generator is a unidirectional energy converter. The electric generator is connected

to an electric power bus through an electronic converter (rectifier). Electrochemical

oattery pack is the bidirectional energy source and is connected to the power bus by

means of a power electronics converter (DC/DC converter). Also the electric power bus

is connected to the controller of the electric traction motor. The traction motor can be

controlled either as a motor (when propels the vehicle) or as generator (to vehicle

oraking). A battery charger can charge batteries with the energy provided by an

electrical network.

[he possible operating modes of series hybrid electric drive trains are [Ehsani, 2005]: 1.](https://figures.academia-assets.com/55507705/figure_031.jpg)

![The dynamic model of ac machine can be developed [Ehsani, 2005], [Husain, 2003], using

the concept of “space vectors”. Space vectors of three-phase variables, such as the voltage,

current, or flux, are very convenient for the analysis and control of ac motors and power

converter. A three-phase system defined by ya(t), ya(t), and yc(t) can be represented uniquely

by a rotating vector y(t) in the complex plane.](https://figures.academia-assets.com/55507705/figure_037.jpg)

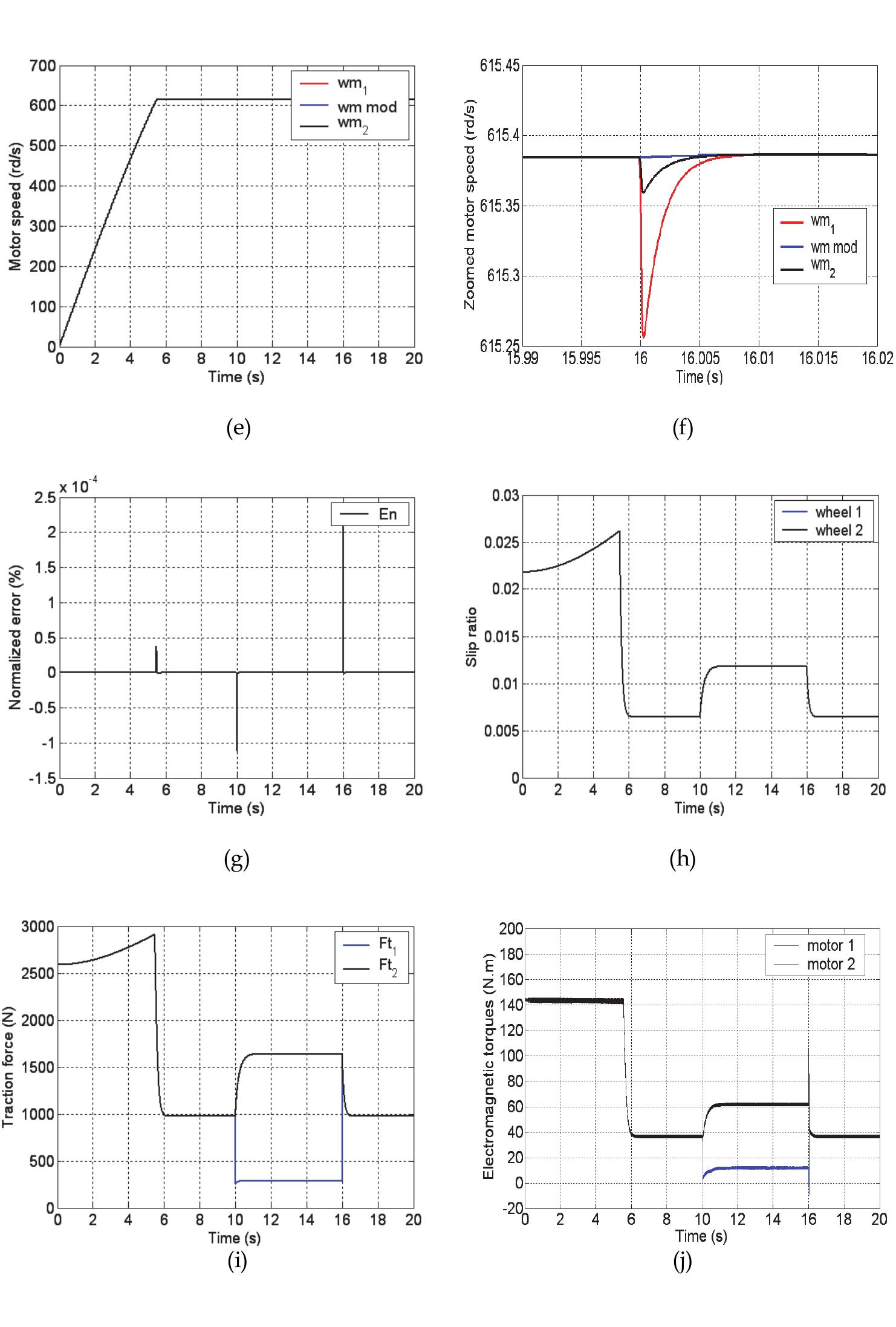

![The structure of the experimental model of the hybrid vehicle is presented in Figure 11. The

model includes the two power propulsion (ICE, and the electric motor/generator M/G)

with allow the energetically optimization by implementing the real time control algorithms.

The model has no wheels and the longitudinal characteristics emulation is realized with a

corresponding load system. The ICE is a diesel F8Q of 1.91 capacity and 64[HP]. The

electronic unit control (ECU) is a Lucas DCN R04080012J-80759M. The coupling with the

motor/ generator system is assured by a clutch, a gearbox and a belt transmission.

The electric machine is a squirrel cage asynchronous machine (15kW, 380V, 30.5A, 50H:

2940 rpm) supplied by a PWM inverter implemented with IGBT modules (6KM200GB122D

The motor is supplied by 26 batteries (12V/45Ah). The hardware structure of th

motor/ generator system is presented in Figure 12. The hardware resources assured by th

control system eZdsp 2808 permit the implementation of the local dynamic contr

algorithms and for a CAN communication network, necessary for the distributed contre

used on the hybrid electric vehicle, [Livint et all 2008, 2010]

With the peripheral elements (8 ePWM channels, 2x8 AD channels with a resolution of 1

bits, incremental transducer interface eQEP) and the specific peripheral for th](https://figures.academia-assets.com/55507705/figure_042.jpg)

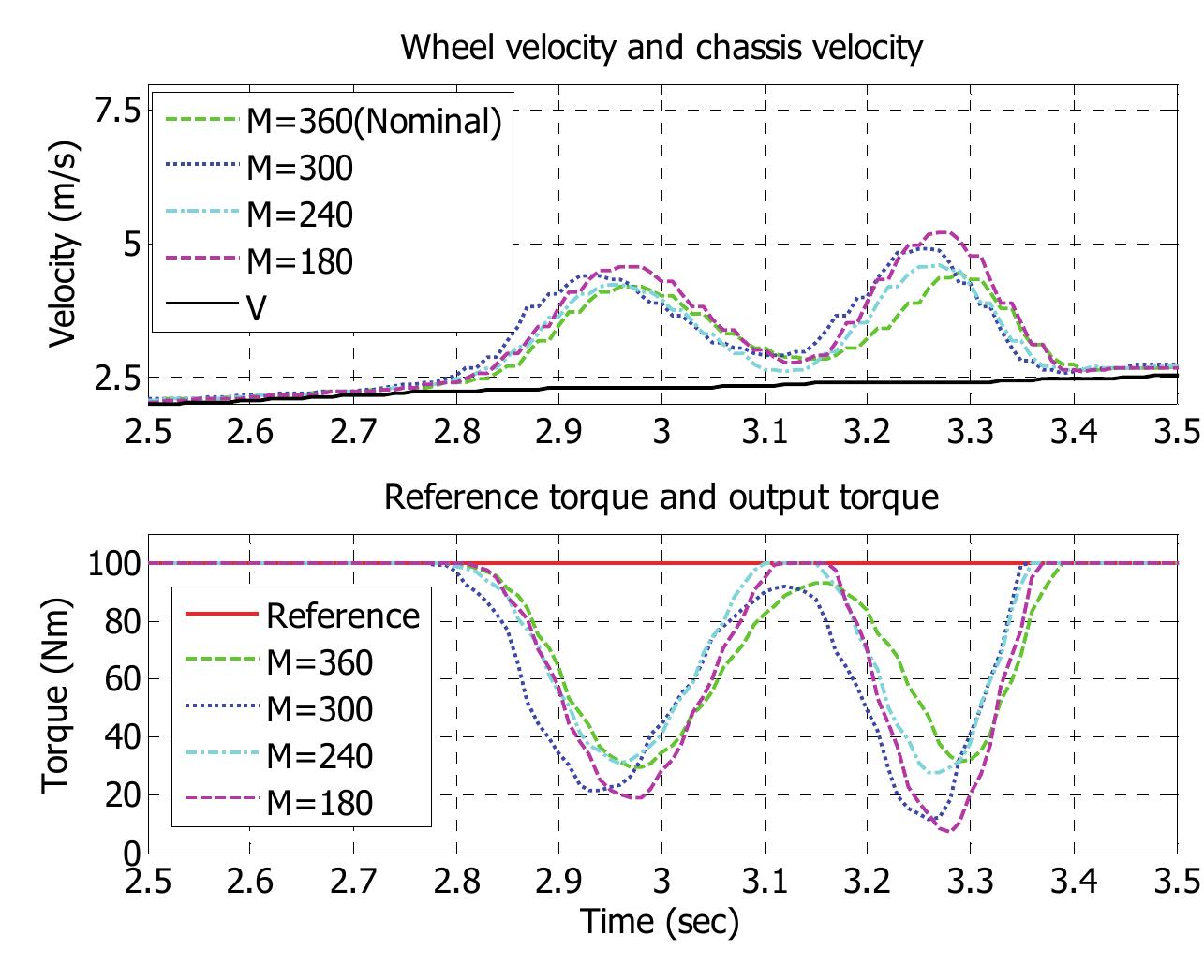

![The standard model of MFC is got under the condition that the slip ratio is set to 0. It means

that the road’s adhesion force isn’t fully utilized and the driving performance will be bad. So

this control strategy is not perfect. Secondly, MFC hasn’t good robustness to the input

signals. Especially when the angular speed is disturbed, deviation of the controller will

happen.

According to the research results from Tokyo University 5], when the tire is completely

adhered, the vehicle’s equivalent mass is equal to the sum of the sprung mass and non-

sprung mass. When the tire slips, the angular speed changes significantly. During

acceleration, the angular speed is obviously smaller than the ideal value which is outputed

by the standard model. In light of this principal, the tire’s angular speed should be

compared to the angular speed from the standard model at any time. And then the

difference is used as the basis for a correction value through a simple proportional control to

adjust the e-motor’s output torque. So that the tire can avoid slipping.

MFC strategy only requires the e-motor’s output driving torque and the tire’s angular speed

signal to put ASR into practice. Consequently the estimation of the longitudinal velocity and

the optimal slip ratio identification can be ignored. Therefore, this strategy is practical. The

te ce I a eB Ne ee ee ek](https://figures.academia-assets.com/55507705/figure_055.jpg)

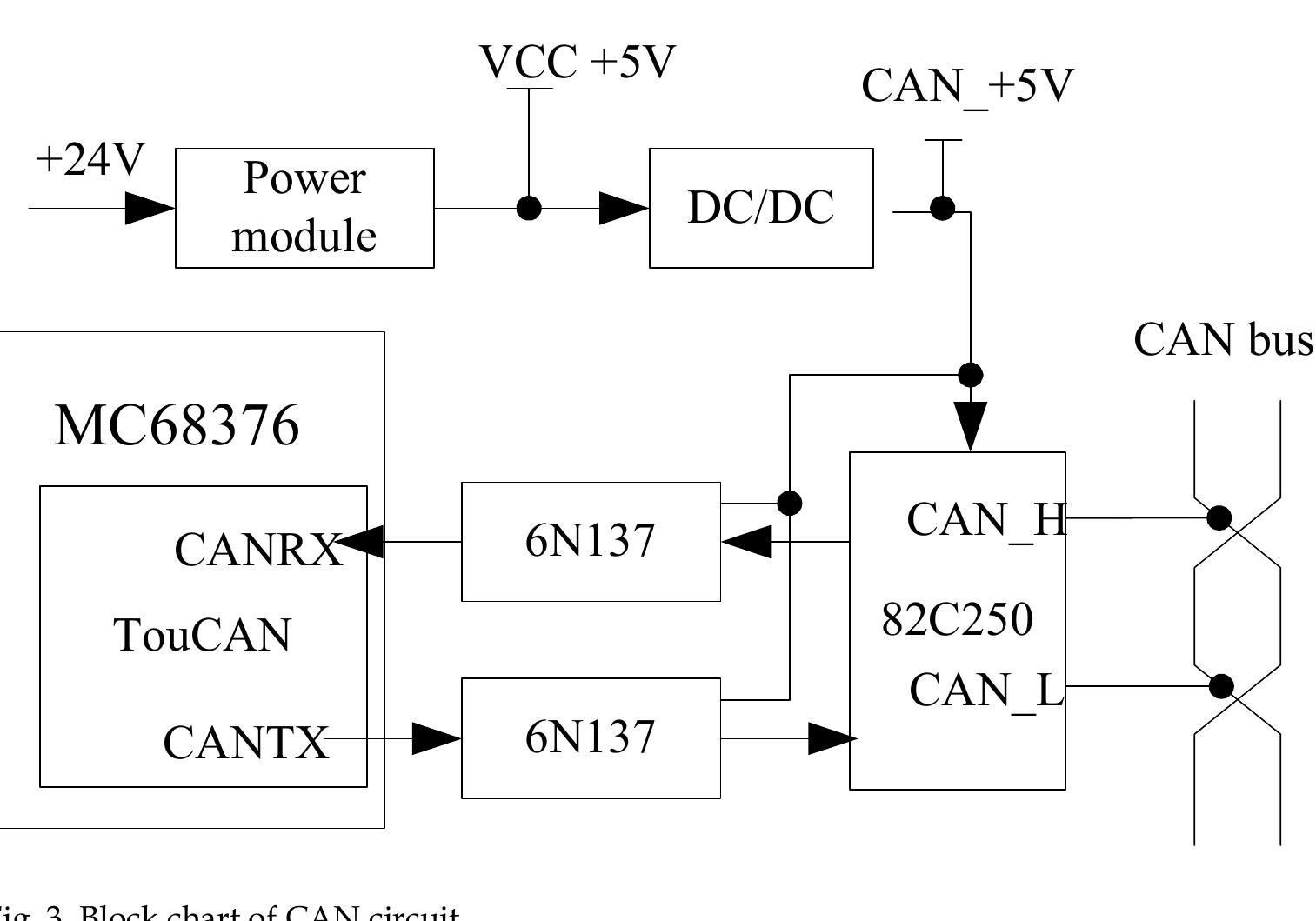

![4.4 CAN Calibration Protocol (CCP)

standardization.

CCP driver is needed for ECU which parameters can be calibrated. A CCP driver software is

integrated in the infra program of HCU. A basic implementation of CCP driver needs only a

few control unit resources such as RAM, ROM, and CPU time. The CCP driver occupies two

CAN buffers, which should be assigned low bus priority to avoid influencing other bus

communication [8]. The trigger mode of CCP driver is interrupt mode. CCP driver is the

foundation of calibration platform. The calibration platform structure is shown as Fig.7. CCP

driver achieves data upload, download and calibration of controlled parameters. This

calibration system provided reliable, accurate and quickly CAN communication between

calibration platform and ECU. It has been used successfully in HEV controlled system.

The maximum bits of each flame TR can be calculated by following equation [7]](https://figures.academia-assets.com/55507705/table_041.jpg)

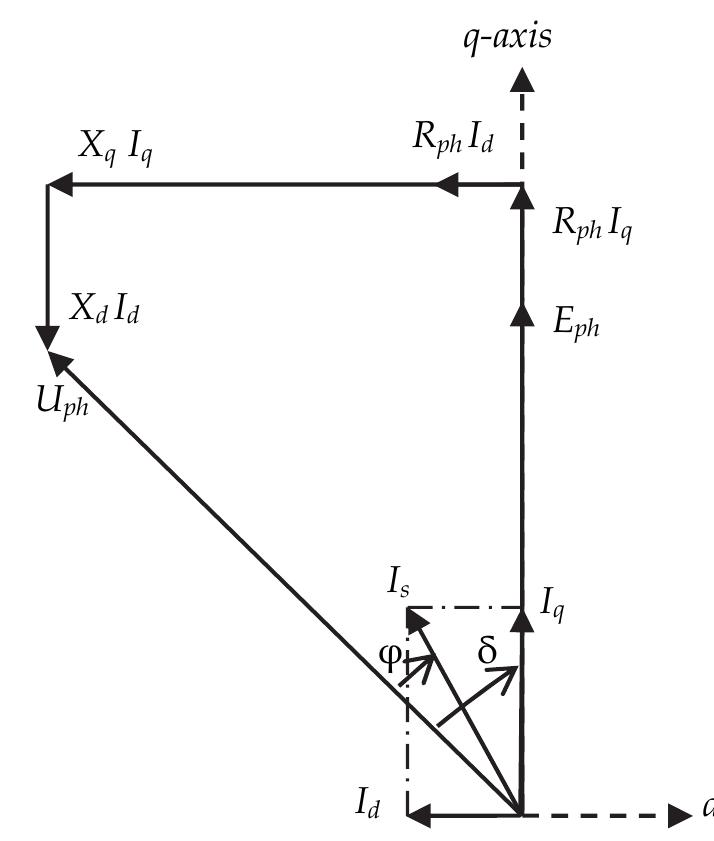

![Fig. 31. Power Factor Comparison

Fig. 30. Motor Power Factor

This value of , can be used to theoretically generate the rms voltage phasors V,;, V, and Vj.

using expressions (VIII), (XC) and (XCIII) in the previous chapter respectively from a

knowledge of the motor winding phasor current Jj; as per Table IV over the i/p torque

demand range range Ty 24V . The quantities obtained from BLMD simulations in Table II]

compare reasonably well with those derived in Table IV from theoretical considerations

which reinforces model validation and confidence. The optimized internal power facto1

angle, which is almost identical to that in Table III, results in a zero load angle Br from

(XCV) in the previous chapter due to the phasor collinearity and thus improved torque

control via the PWM voltage supplied by the current controlled inverter. The power facto1

angle , internal power factor angle @; and machine impedance angle @~, variations with

torque demand i/p, which are displayed in Figure 27 using estimates extracted from BLMD

model simulation in Table II] for [zy 24V, are almost congruent with a mismatched

difference manifested as the negligible load angle (B70).](https://figures.academia-assets.com/55507705/figure_353.jpg)

Related papers

In this paper, the electric vehicles fundamentals, modeling and dynamics are reviewed. In present scenario electric vehicles are key areas for researchers due to the fact of regulations on emissions and fuel economy, global warming and energy resources utilities. To verify the vehicles fundamentals, performances and modeling results of an example has been presented.

1996

Prerequisite Knowledge: Computer science (executing a Fortran program), analysis techniques (plotting numerical results, comparison of simulation runs), vehicle design (some knowledge of components of automobiles). Objectives: To illustrate the changes in performance and fuel economy that result fiom the changes in vehicle characteristics, and to show the application of simulation tools to solve current engineering design problems.

New Generation of Electric Vehicles, 2012

As shown in , the whole vehicle power-train model is composed by many subsystems, connected in according to the energy and information physical exchanges. They represent the driver (pilot), the vehicle control system, the battery, the inverter, the Electrical Motor (EM), the mechanical transmission system, the auxiliary on board electrical loads, the vehicle dynamical model and for, HEVs and Plug-in Hybrid Electrical Vehicles (PHEVs), also an ICE and a fuel tank are considered. To correctly describe them, a multidisciplinary methodology analysis is required. Furthermore the design of a vehicle requires a complete system analysis including the control of the energy given from the on-board source, the optimization of the electric and electronic devices installed on the vehicle and the design of all the mechanical connection between the different power sources to reach the required performances. So, the complete simulation model has to describe the interactions between the system components, correctly representing the power flux exchanges, in order to help the designers during the study. For modeling each component, two different approaches can be used: an "equation-based" or a "map-based" mode [1]. In the first method, each subcomponent is defined by means of its quasi-static characteristic equations that have to be solved in order to obtain the output responses to the inputs. The main drawback is represented by the computational effort needed to resolve the model equations. Vice versa using a "map-based" approach each sub-model is represented by means of a set of look-up tables to numerically represents the set of working conditions. The map has to be defined by means of "off-line" calculation algorithm based on component model equation or collected experimental data. This approach implies a lighter computation load but is not parametric and requires an "off-line" map manipulation if a component parameter has to be changed. For the model developing process, an object-oriented causal approach can be adopted. In fact the complete model can be split into different subsystems. Each subsystem represents a component of the vehicle and contains the equations or the look-up table useful to describe its behavior. Consequently each object can be connected to the other objects by means of input and output variables. In this way, the equations describing each subsystem are not dependent by the external configuration, so every object is independent by the others and can be verified, modified, replaced without modify the equations of the rest of the model. At the same time, it is possible to define a "power flux" among the subsystems: every output variable of an object connected to an input signal of another creates a power flux from the first to the second subsystem ("causality approach"). This method has the advantage to realize a modular approach that allows to obtain different and complex configuration only rearranging the object connection.

IAEME PUBLICATION, 2020

The vehicle modelling and configurations of an EV power-train is analyzed here. Electric Vehicle means, the propulsion power is solely produced by electrical means. Electric Vehicle are enjoying more widespread customer acceptance as personal vehicle because of their performance and economy in running cost. All electric vehicles use a battery pack to store electrical energy that powers the motor. Electric Vehicles are also known as battery electric vehicle. The charging of the battery of an EV can be done by plugging it. Since there is no tail pipe emission, EV’s are considered as the zero emissions vehicles. The modeling of a vehicle and various configurations of EV based on the power train and power source is presented here.

Proceedings of the IEEE, 2007

Tools that can model embedded software as well as components, and can automate the details of electric and hybrid vehicle design, need to be developed.

2015

As electric vehicles become promising alternatives for sustainable and cleaner energy emissions in transportation, the modeling and simulation of electric vehicles has attracted increasing attention from researchers. This paper presents a simulation model of a full electric vehicle on the Matlab-Simulink platform to examine power flow during motoring and regeneration. The drive train components consist of a motor, a battery, a motor controller and a battery controller; modeled according to their mathematical equations. All simulation results are plotted and discussed. The torque and speed conditions during motoring and regeneration were used to determine the energy flow, and performance of the drive. This study forms the foundation for further research and development.

Modeling and Simulation for Electric Vehicle Applications, 2016

The objective of this chapter is to underline the importance of pre-production and prototyping simulation in the loop of electric vehicles, by considering as many vehicle characteristics as possible. Basic simulations were made, using IPG CarMaker, to simulate electric vehicles with different properties for batteries, transmission, electric motors, aerodynamics of the vehicle, and most importantly, driver properties. This chapter also explains all the necessary steps to create a model and run it in IPG CarMaker, including data exports, so that the results could be reproduced easily. This chapter underlines the importance of batteries and answers the questions: what is the correct number of batteries that a vehicle must equip in order to have a bigger range? Basically, one should carry more batteries that add weight but at what range in price.

Mechanics & Industry, 2016

Electric vehicles are by many seen as the cars of the future as they are very efficient, produce no local pollution, are silent, and can be used for power regulation by the grid operator. In order to be able to estimate the performances of an electric vehicle it is very important to have a proper model of it. The electric vehicle model is very complex as it contains many different components. Each component needs to be modelled properly in order to prevent wrong conclusions. The design or rating of each component is a difficult task as the parameters of one component affect the power level of another one. There is therefore a risk that one component is rated inappropriately which may make the vehicle unnecessary expensive or inefficient. In this paper a new design model of the electric vehicle is presented. This model is based on the combination of Modelica with ModelCenter. Modelica has been used to model and simulate the electric vehicle and ModelCenter has been used to optimize the design variables. The model ensures that the requirements related to driving distance and acceleration are fulfilled.

— The aim of this thesis work 'Design of electric vehicle including different power train components' is to design an energy model of electric vehicle including different power train components with the application of a design and simulation tool, which in this thesis work would be MATLAB Simulink software. With this design and simulation, we expect to find the energy consumption by a vehicle by virtue of different types of forces acting on vehicle when subjected to different standard driving cycles. This work also includes a survey of different vehicles which runs on electric propulsion either only or in assisted mode in the present market.

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Related papers

Control Engineering Practice, 2019

International Journal of Vehicle Performance, 2024

IEEE Circuits and Devices Magazine, 2005

Lecture Notes in Mobility, 2015

Vehicular Technology, IEEE …, 2002

Journal of Electronics,Computer Networking and Applied Mathematics

International Journal of Scientific Research in Science and Technology, 2022

Proceedings of the 19th IFAC World Congress, 2014

IAEME Publications, 2020

ACM Journal on Autonomous Transportation Systems, 2024

Proceedings of the 28th International DAAAM Symposium 2017, 2017

Udit Sangwan

Udit Sangwan