Reconocer, identificar y conocer las propiedades de los materiales es muy importante en el campo de la ingeniería, ya que son ellos los que aportan las características de resistencia y estabilidad de lo que se va a diseñar. Si no se... more

Natural fiber reinforced composites is an emerging area in polymer science. These natural fibers are low cost fibers with low density and high specific properties. These are biodegradable and non-abrasive. The natural fiber composites... more

In order to assist researchers explore the full potential of distributed recycling of post-consumer polymer waste, this article describes a recyclebot, which is a waste plastic extruder capable of making commercial quality 3-D printing... more

E-waste management is a serious challenge across developed, transition, and developing countries because of the consumer society and the globalization process. E-waste is a fast-growing waste stream which needs more attention of... more

Megaproject Planning and Management: Essential Readings contains the seminal articles from the growing body of research on megaproject planning and management along with an original introduction by the editor, Bent Flyvbjerg. The leading... more

The articles in this issue look at how the development and use of free and open source hardware (FOSH or simply “open hardware”) are changing the face of science, engineering, business, and law. Free and open source software (FOSS) has... more

— This investigation present a new method for reducing electrical field in power electrical substation and also it has been paid attention to health personnel who work in this place therefore the health of staff has been a priority. In... more

Important experimental parameters for FTIR spectra acquisition were studied: apodization, beam aperture, number of scans and spectral resolution, using polyethylene samples. The optimum conditions for the analyses were established and... more

TD Matériaux métalliques TLILI A. 2 4. Combien y a-t-il de réactions eutectiques dans ce diagramme ? Écrivez ces réactions, indiquez leur température et les compositions des phases en présence. 5. Quels sont les phases et les constituants... more

The solar photovoltaic (PV) market continues to grow rapidly throughout the world [1] offering the promise of enabling humanity to utilize sustainable and renewable solar power technology to run society [2]. As the PV industry has grown,... more

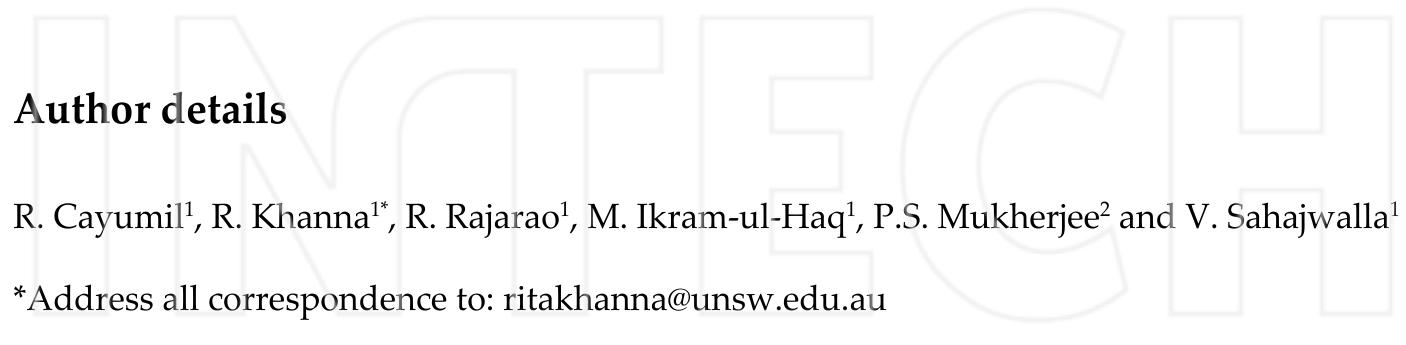

This research was funded by, and implemented within, a UK national research organisation, while the author was the KE and Impact Evaluation Manager responsible for assessing impact on a £15m UK government-funded research programme. This... more

— Theory of Eight Palaces (八宫) or Eight Veins (八 脉) is useful in understanding economic disease. By using mathematical reasoning based on Yin Yang Wu Xing Theory in Traditional Chinese Economics (TCE), this paper demonstrates the... more

Chitin is the most abundant natural amino polysaccharide and is estimated to be produced annually almost as much as cellulose. It has become of great interest not only as an underutilized resource, but also as a new functional material of... more

Ultrafine grained steels with grain sizes below about 1 μm offer the prospect of high strength and high toughness with traditional steel compositions. These materials are currently the subject of extensive research efforts worldwide.... more

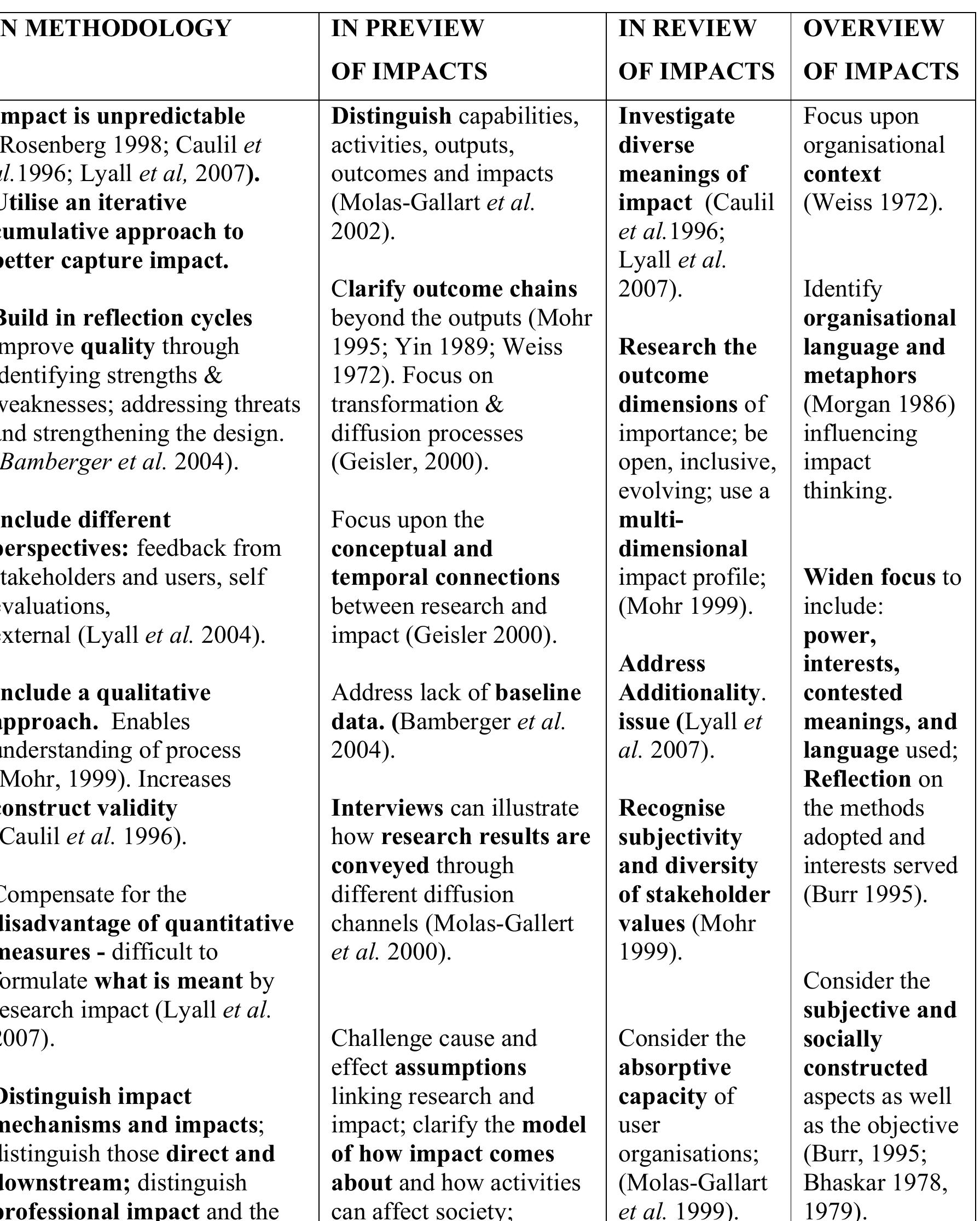

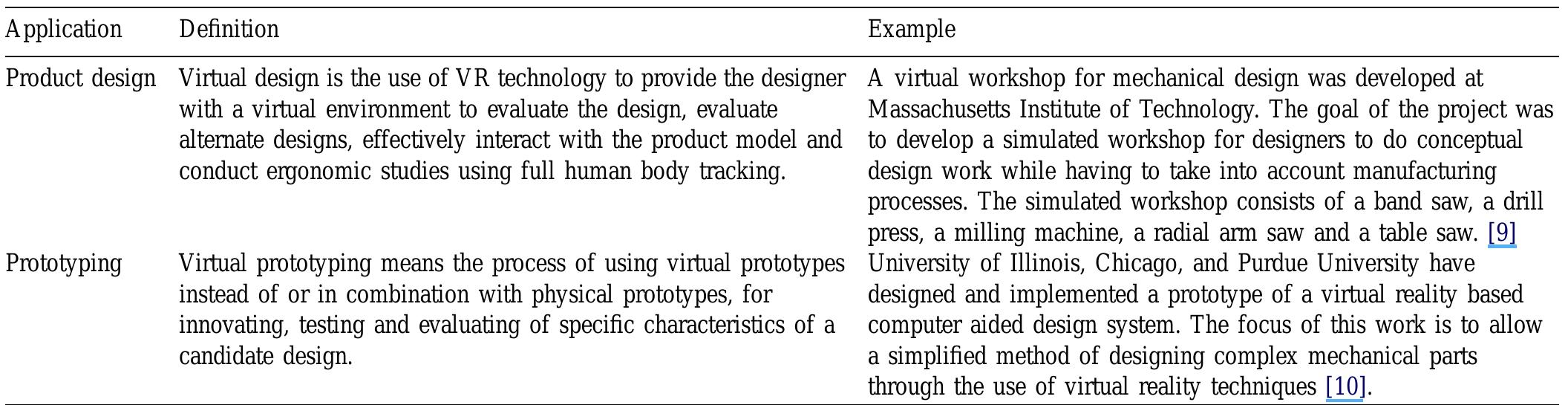

The paper provides an overview of tribological properties of nanocomposites with aluminium matrix. Nanocomposites represent a new generation of composite materials with better properties than conventional composite materials. The paper... more

This paper analyses wear behaviour of Al-Si alloy A356 (AlSi7Mg) based composite reinforced with 10 wt. % SiC, and compare it with the base A356 alloy. Composite are obtained using the compocasting procedure. Tribological testing have... more

Hak Cipta dilindungi Undang-Undang Dilarang memperbanyak karya tulis ini dalam bentuk dan dengan cara apapun tanpa ijin tertulis dari penerbit iii Puji syukur kita panjatkan kehadirat Tuhan Yang Mahaesa sehingga Buku Struktur dan Rekayasa... more

Abstract— Theory of Eight Palaces (八宫) or Eight Veins (八 脉) is useful in understanding economic disease. By using mathematical reasoning based on Yin Yang Wu Xing Theory in Traditional Chinese Economics (TCE), this paper demonstrates... more

This Intergovernmental Panel on Climate Change (IPCC) Special Report provides information for policymakers, scientists and engineers in the field of climate change and reduction of CO2 emissions. It describes sources, capture, transport,... more

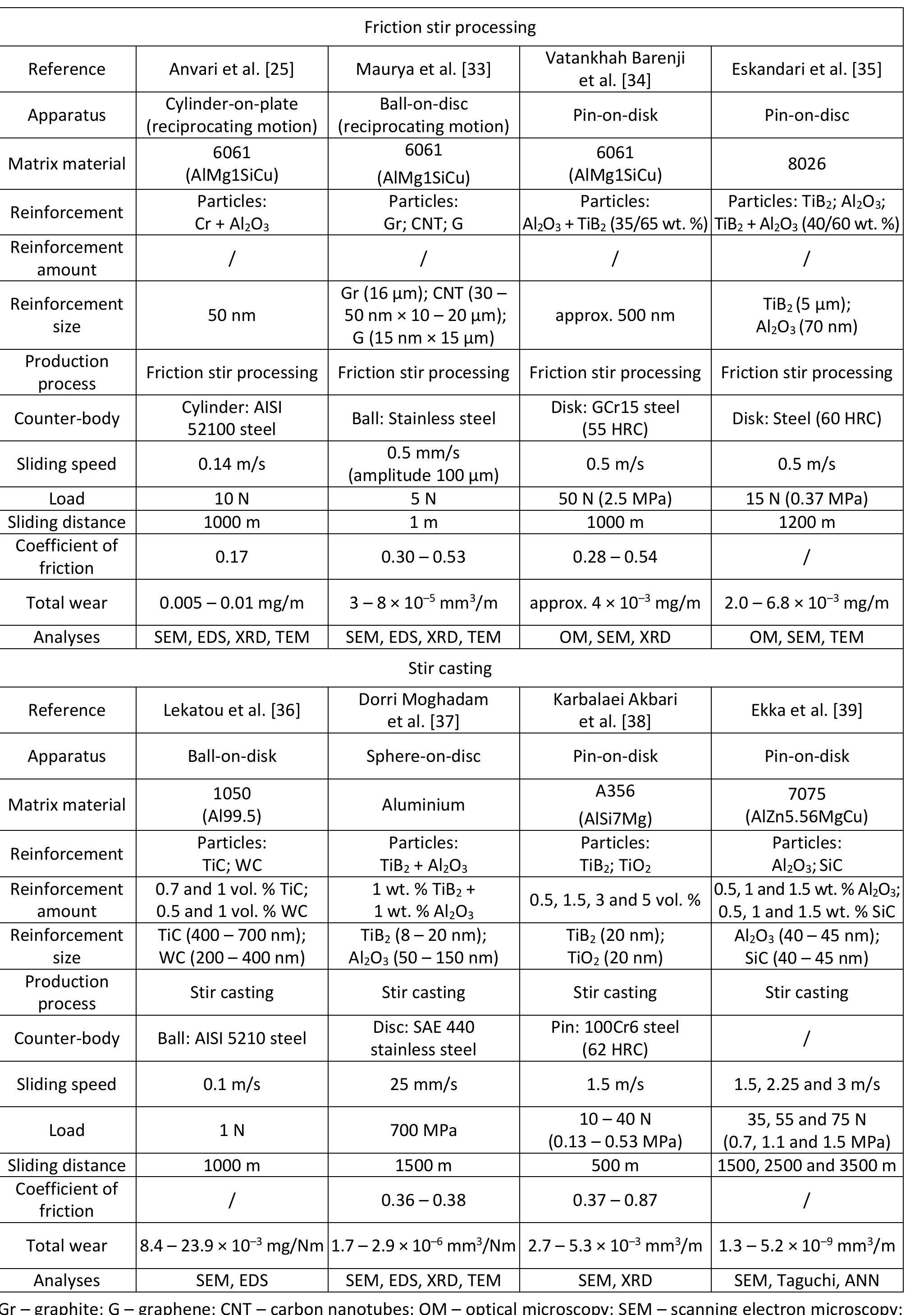

Virtual reality (VR) is a rapidly developing computer interface that strives to immerse the user completely within an experimental simulation, thereby greatly enhancing the overall impact and providing a much more intuitive link between... more

Silver nanoparticles were successfully synthesized from AgNO 3 through a simple green route using the latex of Jatropha curcas as reducing as well as capping agent. Nanoparticles were characterized with the help of HRTEM, X-ray... more

To reduce greenhouse gas emissions, efforts are needed to develop environmentally friendly construction materials. This paper presents the development of fly ash-based geopolymer concrete. In geopolymer concrete, a by-product material... more

Back cover text: Megaprojects and Risk provides the first detailed examination of the phenomenon of megaprojects. It is a fascinating account of how the promoters of multi-billion dollar megaprojects systematically and self-servingly... more

Development of green nanotechnology is generating interest of researchers toward ecofriendly biosynthesis of nanoparticles. In this study, biosynthesis of stable silver nanoparticles was done using Tulsi (Ocimum sanctum) leaf extract.... more

Recent progress in the recycling and recovery of polyurethane and polyurethane composites is reviewed. The various types of polyurethane waste products, consisting of either old recycled parts or production waste, are generally reduced to... more

The paper deals with the considerations related to the basic properties and application of primarily aluminum alloys and composite materials for different purposes with the focus on the automotive industry. Through the description of the... more

Strict requirements that are put on mechanical constructions from the aspect of increase of exploitation periods and reduction of their weights, therefore of their prices as well, implicate developments and applications of new composite... more

Gelagar T beton bertulang konvensional sudah sangat lazim digunakan terutama pada struktur jembatan dengan bentang 5m -25m. Akan tetapi sebenarnya, berat sendiri jembatan murni beton bertulang sangatlah berat. Pelaksanaan jembatan balok T... more

Abstract— Theory of Sixty JiaZi (60 甲子) is useful in understanding economic disease. By using mathematical reasoning based on Yin Yang Wu Xing Theory in Traditional Chinese Economics (TCE) , this paper demonstrates the treatment... more

Introducing a new engineering product or changing an existing model involves making designs, reaching economic decisions, selecting materials, choosing manufacturing processes, and assessing its environmental impact. These activities are... more

We stand at the threshold of a New Renaissance in science and technology, based on a comprehensive understanding of the structure and behavior of matter from the nanoscale up to the most complex system yet discovered, the human brain.... more

0 − ) 0 ⁄ ( − 0 ) 0 ⁄ Ce coefficient permet de déterminer le module d'élasticité transversal G lorsqu'on connaît le module d' Young : = ×( + )

Your article is protected by copyright and all rights are held exclusively by Springer Science +Business Media Dordrecht. This e-offprint is for personal use only and shall not be selfarchived in electronic repositories. If you wish to... more

The components of a gas turbine operate in an aggressive environment where the temperature of service varies from ambient to near melting point of materials which introduce a variety of degradation on the components. Some components that... more

Abstract— Theory of Eight Palaces (八宫) or Eight Veins (八 脉) is useful in understanding economic disease. By using mathematical reasoning based on Yin Yang Wu Xing Theory in Traditional Chinese Economics (TCE), this paper demonstrates... more

The manufacturing cost of WT blade is about 15-20% of wind turbine production cost. The expenses of innovations in design of blades represent the small amount of overall cost of wind turbine production. Profits coming from better... more

The Supplementary Green Book Guidance on Optimism Bias (HM Treasury 2003) with reference to the Review of Large Public Procurement in the UK (Mott MacDonald 2002) notes that there is a demonstrated, systematic, tendency for project... more

PREFAZIONE "Metallurgia degli Acciai": l'opera per continuare a raccontare i nostri materiali e la nostra storia... perchè, da sempre, noi ci crediamo! Crediamo in quello che facciamo, con professionalità, impegno e dedizione. Crediamo... more

ABSTRAK: Abu terbang dan abu dasar adalah sisa hasil proses pembakaran batu bara, merupakan limbah yang meningkat setiap tahunnya, sehingga diperlukan penanggulangan. Perbedaan perlakuan terhadap abu batu bara membuat variasi kandungan... more

... based systems (both Bragg and Long Period), luminescent fiber sensors, plastic fiber sensors and ... to conform to this pattern, providing a useful means of systems analysis and identification. ... are now commercially available, and... more

A critical review of the literature on the various aspects of natural fibers and biocomposites with a particular reference to chemical modifications is presented in this paper. A notable disadvantage of natural fibers is their polarity... more

Nikel adalah komponen yang banyak ditemukan dalam meteorit dan menjadi ciri komponen yang membedakan meteorit dari mineral lainnya. Meteorit besi atau siderit, dapat mengandung alloy besi dan nikel berkadar 5-25%. Nikel diperoleh secara... more

![Figure 3. Comparison of PCDD/Fs- and PCBs-TEQ in human body fat from various countries [17-19, 23, 24, 28-30].](https://figures.academia-assets.com/47154028/figure_010.jpg)

![Figure 5. Comparison of PCBs concentrations (ng/g lipid) in children’s blood between polluted areas (LQ) and control areas (LY and TT) [39]. Different from the results of PCBs, PCDD/Fs levels in children’s blood of the heavily pollute area LQ (206 + 157 pg/g lipid) were shown to be higher than the moderately polluted area T (160 + 102 pg/g lipid), but lower than the control area LY (282 + 261 pg/g lipid). Integrate analysis of the data for the three areas was performed, and the average PCDD/Fs level | children’s blood was 208 + 172 pg/g lipid (54.4-784 pg/g lipid) (Figure 5). Our previous stuc also revealed that PCDD/Fs levels in food (primarily fish and egg) in LY were about 3- to. fold of those in LQ. In 1960s, PCB-Na was abundantly produced and extensively applied | control schistosomiasis in LY. But during the production of PCP-Na, a large amount of PCDI Fs was generated. PCDD/Fs are persistent and can bioaccumulate through food chai eventually enter human body [44]. These results in our studies indicate there still exists gre health risk to the environment and population due to historically widespread application | PCP-Na in LY.](https://figures.academia-assets.com/47154028/figure_012.jpg)

![elements. Materials such as gold and palladium can be mined more effectively from e-waste compared to mining from ore [28]. By contrast, e-waste contains PBDEs, which are flame retardants that are mixed into plastics and other components. Circuit boards found in most of the electronic devices may contain arsenic (As), cadmium (Cd), chromium (Cr), lead (Pb), mercury (Hg), and other toxic chemicals. Typical printed circuit boards treated with lead solder in electronic devices contain approximately 50 g of tin-lead solder per square meter of circuit board [7]. Obsolete refrigerators, freezers, and air conditioning units contain ozone depleting Chlorofluorocarbons (CFCs). The prominent materials such as barium, cadmium, copper, lead, zinc, and other rare earth metals are contained in end-of-life (EOL) cathode ray tubes (CRTs) in computer monitors, and televisions. For example, items such as leaded glass provide protection against X-rays produced in the picture projection process in CRTs [6]. The average lead in CTR monitors is 1.6-3.2 kg. Thus, the US and other developed countries in the EU and Japan have banned the disposal of cathode ray tubes in landfills because of their toxic charac- teristics. A critical challenge in designing and developing strategies to manage e-waste is the changing composition of the many constituents due the advancement of technology, particu- larly in the electronic components [24]. It is against this background that e-waste recycling and disposal methods ought to keep pace with the changing composition of e-waste. Several factors influence the composition of e-waste, including economic conditions, availability of a reuse market, and infrastructure of the recycling industry, waste segregation programs, and regulation enforcement. Figure 1 illustrates the distinctive materials ina WEEE. E-waste generated from the different diverse sources is normally collected as a whole unit or sub-unit of functional equipment. In many instances across the globe, whole units of e-waste](https://figures.academia-assets.com/47154028/figure_013.jpg)

![Figure 2. Flow of the take back system in Japan. Source; Adapted from [58].](https://figures.academia-assets.com/47154028/figure_014.jpg)

![State-wise E-waste Generation in India (Tonnes/year) Figure 5. State-wise e-waste generation in India. The results of a field survey conducted in Chennai, a metropolitan city of India, to assess the average usage and life of the personal computers (PCs), televisions (TVs), and mobile phones demonstrated that the average household usage of the PC ranges from 0.39 to 1.70 depending on the income class [49]. Although the per-capita waste production in India is still relatively small, the total absolute volume of wastes generated is gigantic, and it continues to grow at an alarmingly fast rate. The growth rate of mobile phones (80%) is very high compared to that of PCs (20%) and TVs (18%). The public awareness on e-wastes and the willingness of the public to pay for e-waste management, as assessed during the study, based on an organized ques- tionnaire revealed that about 50% of the public are aware of environmental and health impacts of EOL electronic items. The willingness of the public to pay for e-waste management ranges from 3.57% to 5.92% of the product cost for PCs, 3.94% to 5.95% for TV and 3.4% to 5% for the mobile phones [50].](https://figures.academia-assets.com/47154028/figure_030.jpg)

![Figure 6. E-waste generation in India: Past and forecasts for the future. There are over 75 million mobile users and the number has increased to 200 million as of 2008 [57]. An estimated 30,000 computers become obsolete every year from the IT industry in Bengaluru alone [58]. India has about 15 million computers and the base is expected to grow to 75 million computers by 2010 since the life cycle of a PC has come down to 3-4 years from 7 to 8 years a few years back, and the segment is suffering from an extremely high obsolescence has jumped from 50,954 in 2002-2003 to 4,31,834 in 2005-2006 having registered an astonishing growth rate of 143% in 2005-2006 [48,52]. The overall PC sales in 2012-2013 considerably slowed down and the sales figure are well below the expectations. The overall sales figures touched 11.31 million in 2012-2013, registering a growth of 5% over the last fiscal. Desktop PCs continued to dominate the sales proceedings contributing around 60% of the sales although it is somewhat lesser than last year's contribution of 63%. Notebook sales posted a muted growth rate of 10% in 2012-2013 compared to the 22% rate in the previous year. Tablet PCs witnessed a massive growth rate of 424%. The sales for 2012-2013 stood at 1.9 million units as against 0.36 million units in 2011-2012 [53]. Sixty-five cities in India generate more than 60% of the total e-waste generated in India. Ten states generate 70% of the total e-waste in India [54]. Maharashtra ranks first followed by Tamil Nadu, Andhra Pradesh, Uttar Pradesh, West Bengal, Delhi, Karnataka, Gujarat, Madhya Pradesh, and Punjab in the list of e-waste gener- ating states in India (Figure 6). According to forecast, based on a logistic model and material flow analysis [55], the volume of obsolete PCs generated in developing regions will exceed that of developed regions by 2016-2018. By 2030, there would be two obsolete PCs in the developing world for every obsolete PC in the developed world. Similar forecasts have been arrived independently [56]. The advent of LCD, plasma, and larger screens has changed the way India views television and this has translated into phenomenal growth in sales, resulting in a considerable surge in rate of disposal as well.](https://figures.academia-assets.com/47154028/figure_031.jpg)

![Figure 7. Union Miniere Company's copper-smelting flowsheet for recycling of scrap IC board [14]. p: density (10° kg/m), o: electrical conductivity of material (10*/Om). The separation of metallic components through magnetic and eddy current separators are in vogue, wherein, ferrous components are separated, aided either by a permanent magnet or electromagnet, while metals such as aluminum and copper from non-metallic materials are separated in eddy current separator. Table 5 shows the materials that can be separated by eddy current separator. The main separation criteria is 0/9 [75]. On the basis of information provided by the Union Miniere Company [14], Figure 7 presents a copper-smelting flowsheet for recycling of scrap IC boards that is ideally carried out in a primary copper smelting plant, however, such facilities are not well-established in most parts of the world. Thus, removal of the non-recyclable materials (e.g., epoxy resin and fiber glass) from the IC board to enhance the value of recyclable material is preferable since post-separation provides higher metal concentration in lesser volume, thereafter the enriched metal content can then be sold and transported to an appropriate recycling facility for further processing [14]. transported to an appropriate recycling facility for further processing [14].](https://figures.academia-assets.com/47154028/figure_032.jpg)

![Figure 8. Huei-Chia-Dien Company's physical separation flowsheet for recycling of scrap IC boards [14]. Generally, this type of separation plant comprises of a series of physical treatment units devoted to processes such as crushing, grinding, screening, magnetic separation, air classifi- cation, eddy-current separation, electrical-conductivity separation, etc., wherein varied metal fragments of various size and content are obtained, depending on the separation technique and units deployed. The varied metal fragments, except iron, usually contain multiple types of metals, thus, identifying appropriate recycling markets for such mixed metal fragments is imperative [14]. There being no necessity of either water or chemical additive in the processing method, there is no wastewater-associated pollution issue, however, special attention should be provided with respect to dust and noise pollution. The low capital and operational cost in a physical separation plant for IC board recycling, being much less compared with a copper- smelting plant, is undoubtedly an added advantage of immense significance. On the basis of information provided by Huei-Chia-Dien Company, Taiwan [14], Figure 8 presents a physical separation flowsheet for the recycling of scrap IC boards.](https://figures.academia-assets.com/47154028/figure_033.jpg)

![Figure 9. Process flow chart for the technology developed for precious metals at CSIR-NML, Jamshedpur [77]. Processing technology has been successfully developed for the recycle and reuse of e-waste at Council of Scientific and Industrial Research—National Metallurgical Laboratory (CSIR-NML), Jamshedpur, India, in which metal bearing e-waste components were shredded and pulver- ized at the initial operation stage. Subsequently, the metals are separated from the plastics in the particulate mass, adopting a series of physical separation processes. The process does not require much specialized and sophisticated equipment for processing of waste PCBs, since the said equipment and machinery required are readily available, however, its efficiency, espe- cially with respect to commercial viability needs to be further worked upon [76]. The natural hydrophobicity of non-metallic constituents is effectively exploited by a flotation process and a continuous operation at plant level can reasonably be expected to minimize the loss of ultrafine metal values to a negligible level. The operation is simple and the overall](https://figures.academia-assets.com/47154028/figure_034.jpg)

![Pyrometallurgical processing techniques, including conflagrating, smelting in a plasma arc furnace, drossing, sintering, melting, and varied reactions in a gas phase at high temperatures for recovering non-ferrous metals, as well as precious metals from e-waste, happens to be the conventional method deployed in the past two decades, wherein, the crushed scraps are liquefied in a furnace or in a molten bath to remove plastics and in the process, the refractory oxides form a slag phase together with some metal oxides. In the precious metals refinery setup, gold, silver, palladium and platinum are recovered. The anode slime from the copper electrolysis process is subjected to pressure leaching, followed by drying of the leach residue and the same after addition of fluxes is smelted in a precious metals furnace, leading to the recovery of selenium. The remaining material, primarily silver, is cast into a silver anode, subsequently when subjected to a high-intensity electrolytic refining process, a high-purity silver cathode and anode gold slime are formed while leaching of anode gold slime leads to precipitation of high-purity gold, as well as palladium and platinum sludge. Figure 10 shows the precious metals recovery process. Recovery of precious metals from electronic scraps factually is the key to its commercial exploitation by the recycling industry, for profiteering, in the backdrop of the fact that e-scrap contains more than 40 times the concentration of gold content in gold ores found in the US [79], which is almost one-third the precious metal recovered in e-waste processing. The extraction of the precious metal is carried out by the well-established techniques that are discussed in detail in various articles [80-83]. Various methodologies such as pyrometallurgy, hydrometallurgy, and bi-hydrometallurgy technologies are analyzed for the recovery of gold and also the evaluation of recovery efficiency of gold from e-waste has been reviewed [84].](https://figures.academia-assets.com/47154028/figure_035.jpg)

![Figure 12. Schematic diagram for the Rénnskar Smelter [31]. Umicore published [30, 87] its precious metals refining process at Hoboken, Belgium, which is primarily focused on the recovery of precious metals from e-waste. Various industrial wastes and by-products from other non-ferrous industries (e.g., drosses, matters, speiss, anode slimes), sweeps of precious metals and bullions, spent industrial catalysts, as well as consumer recyclables such as car exhaust catalysts or PCBs are acceptable for the integrated metals smelter and refinery process. The plant treats around 2,50,000 tons of varied wastes per annual, Figure 11. Schematic diagram for the Noranda Smelting Processing [85].](https://figures.academia-assets.com/47154028/figure_036.jpg)

![Figure 13. Flowsheet for Umicore's integrated metals smelter and refinery [30]. out of which electronic waste presently comprises up to 10% of the feed [30]. It is the world's largest precious metals recycling facility with a capacity of over 50 tons of PGMs, over 100 tons of gold, and 2400 tons of silver [88]. The first step in the precious metals operations (PMO) is smelting by using an IsaSmelt furnace. Plastics or other organic substances that are contained in the feed partially substitute the coke as a reducing agent and energy source. The smelter separates precious metals in copper bullion from most other metals concentrated in a lead slag, which are further treated at the Base Metals Operations (BMO). The copper bullion is subse- quently treated by copper-leaching and electrowinning and precious metals refinery for copper and precious metals recovery. The Bace Metale Onerations process bv-nrodiicts from the PMQ). The main pnrocessine stens](https://figures.academia-assets.com/47154028/figure_038.jpg)

![The flowchart (Figure 14) shows two methods of recycling scrap mobile phones developed in Korea [38]. The first method (process I) involves shredding of waste PCBs and shipment to a copper smelter. The second method (process II) comprises of shredding, conflagration, melting or converting to copper alloy containing precious metals, and subsequent refining adopting the hydrometallurgical route. However, the systemic operation of recycling for e-waste processing operations in Korea does not in true sense function effectively since the majority of waste mobile phones collected are exported or conflagrated and landfilled, while only 2.5% of the waste mobile phones collected are actually processed for recycling. A pilot plant to recover cobalt from spent lithium-ion batteries of waste mobile phones is under operation, taking into account the high-valuation of cobalt. Figure 14. Flow sheet for the recycling of metal values from waste mobile phones in Korea [38].](https://figures.academia-assets.com/47154028/figure_039.jpg)

![Many researchers have established that a clear definition of e-waste is needed due to rapid technological changes and enhancement, which are shortening the lifespan of the electronic products [8-10]. To date, the widely accepted definition in different e-waste studies is by the EU WEEE Directive, which defines e-waste as “Electrical or electronic equipment (EEE) which is Anelectrical and electronic product can be classified as a product that contains a printed circuit board (PCB) and uses electricity. Much has been written about the e-waste problem, yet the definition of the term "electronic waste" is quite complex to define. Referring to scholarly literature on the topic, there is, as yet, no standard definition, as every country has its own definition of e-waste. The questions that arise, therefore is: What is to be called e-waste? Any electronic or electrical appliances, which are obsolete in terms of functionality? Products that are operationally discarded? Or is it both? [10]. Table 1 gives a list of the different definitions of e-waste.](https://figures.academia-assets.com/47154028/table_007.jpg)

![Disposal of e-waste is mainly through landfilling. Most often, the discarded electronic goods finally end-up in landfill sites along with other municipal waste or are openly burnt releasing toxic and carcinogenic substances into the atmosphere. In developing and transition countries the disposal of e-waste in the informal sector is very rudimentary so far as the safe techniques employed and practices are concerned, resulting in low recovery of materials [38]. Table 3 presents a comparison of typical disposal systems in developed and developing countries. presents a comparison of typical disposal systems in developed and developing countries. E-waste management is different between developed countries and developing and transition countries. Developing and transition countries do not have guidelines and information campaigns on the fate of e-waste. Especially, less sophisticated disposal systems are used, from open burning and dumping to uncontrolled landfill sites, which pose significant environmental pollution and occupational exposure to e-waste-derived chemi- cals [31]. Serious challenges in the disposal of e-waste were analyzed across developing countries such as Brazil [19], China [42], and India [43], outlining the difficulty to implement/ enforce existing regulations and clean technologies backed by lack of capacity building and awareness. In contrast, developed countries have devised sophisticated disposal schemes and high-cost systems, which are less hazardous to handle waste. However, a comprehen- sive overview of the situation is constrained by the availability of data. This means that the differences in the socio-economic and legal contexts between typical developing and developed countries’ scenarios limit e-waste management in developing and transition countries. The regulations that guide the disposition of e-waste in developing countries is mostly fragmented and lack monitoring, while in developed countries the regulations are stringent and there is effective monitoring [36].](https://figures.academia-assets.com/47154028/table_008.jpg)

![Table 1. E-waste sources and their health effects. 4.9. Health and environmental impact of e-waste EOL of electrical and electronic equipments comprise numerous components, many of whicl are inherently hazardous and highly toxic in nature, which if not arrested through scientifical]; sustainable recycling and disposal, can lead to a disastrous impact on life, environment, anc climate as well. Certain examples of sources of e-waste and their related adverse health impact are listed in Table 1 [23]. However, if handled in a controlled environment and disposed-of adopting safe and sustainable methodology, these e-wastes provide immense value additio1 and new product cycle, driving great economic prospect, without posing risks to life, envi ronment, and climate. However, haphazard recycling and disposal of e-waste by the unor ganized sector without access to adequate technology and resources, guided by profit-onl} motive can have damaging consequences to inhabitants and the environment, including bu not limited to the workforce engaged in this trade, groundwater pollution, etc., especially or account of highly toxic release into the soil, air, and ground water [23].](https://figures.academia-assets.com/47154028/table_011.jpg)

![Given the diverse range of materials found in WEEE, it is difficult to give a generalized material composition for the entire waste stream. However, most studies examine five categories of materials: ferrous metals, non-ferrous metals, glass, plastics, and others. Figure 1 shows the material fractions in e-waste [2]. Metals are the major common materials found in e-waste representing about 60%. Plastics are the second largest component by weight representing about 15%. Figures 2—4 shows the material composition of a personal computer [25, 26], followed by television sets [27] and mobile phones [28].](https://figures.academia-assets.com/47154028/table_012.jpg)

![The content or substances in cellular phone are variable to some extent, based on the model and its manufacturer, with no fixed formula or list of contents applicable as such, thus, the list of substances in an average mobile phone may also be misleading since varied substances might be used as additives in very minimal quantities or traces by different manufacturers in the production of microelectronic components. However, the general composition of cellular phones and other small electronic goods as well, is identical in nature. Table 6 presents the fractional composition of a modern cell phone [89]. Recovering metals of higher percentage concentration like copper and metals of precious value or worth like gold, palladium and silver is factually the underlying objective for metal recovery from EOL or obsolete cellular phones and aluminum or magnesium cases of cellular phones wherever applicable, contribute further to value addition or generation through its recycling.](https://figures.academia-assets.com/47154028/table_015.jpg)

![Fig. 1. Structures of cellulose, chitin and chitosan. chitin, chitosan and their derivatives. However, these naturally abundant materials also exhibit a limitation in their reactivity and processability [3,4]. In this respect, chitin and chitosan are recommended as suitable functional materials, because these natural polymers have excellent properties such as biocompatibility, biodeg-](https://figures.academia-assets.com/49089022/figure_001.jpg)

![Fig. 2. Controlled drug delivery versus immediate release. Chitosan is non-toxic and easily bioabsorb- able [74] with gel-forming ability at low pH. Moreover, chitosan has antacid and antiulcer activities which prevent or weaken drug irrita-](https://figures.academia-assets.com/49089022/figure_003.jpg)

![Table 1. Continued The amount of nanosized reinforcing ceramic particles was usually up to 5%, but was is also noticed that it can be up to 10%. Nevertheless, these amounts were lower than the amounts used for the micro-sized reinforcing particles, which can be up to 20 % [9]. For example, sliding speeds were in the range from 1 mm/s to several m/s, and applied loads from 0.1 MPa to several hundreds MPa, and it is well-known that coefficient of friction and especially wear depend very much on these conditions. The important thing to note is that many authors did not present all the experimental details and that some of them even made mistakes in presenting the results. The obvious mistakes were corrected, while the presenting of testing conditions and results was uniform as much as it was possible.](https://figures.academia-assets.com/51456906/table_003.jpg)

![it is becoming increasingly difficult to meet customers’ demands and to compete. The advances in virtual reality technology in the last decade have provided the impetus for applying VR to different engineering applications such as product design, modelling, shop floor controls, process sim- ulation, manufacturing planning, training, testing and veri- fication. VR holds great potential in manufacturing applica- tions to solve problems before being employed in practical manufacturing thereby preventing costly mistakes. Virtual reality not only provides an environment for visualisation in the three-dimensional environment but also to interact with the objects to improve decision making from both qualitative and quantitative perspectives [8]. The following section discusses the use of virtual reality in manufacturing applications, which include, design, prototyping, machin- ing, assembly, inspection, planning, training and simulation. Virtual reality applications in manufacturing have been classified into three groups; operations management, man- ufacturing processes, and design. A brief description of every group and its relevant subgroups will be provided in the coming sections. product in the virtual environment. At this stage, functional experimentation of mechanical sembly, etc. could be performed to evaluate the conceptual design and modifications could product, which are to be inves neering analysis, manufacturing typing should include [6]. features such as hinges, as- be made as required. Once the designers are satisfied with their design, then the de- sign could be detailed to make the necessary modifications. n the product development process, prototyping is an es- sential step. Prototypes represent important features of a tigated, evaluated, and im- proved. Virtual prototyping could be used before building the physical prototype to prove design alternatives, to do engi- planning, support manage- ment decisions, and to get feedback on a new product from prospective customers. The virtual environment for proto-](https://figures.academia-assets.com/52463751/table_002.jpg)

![summary for virtual reality benefits in manufacturing applicatior 1.2.3.2. Assembly. Virtual assembly is a key component of virtual manufacturing and is defined as: “the use of computer tools to make or “assist with” assembly-related engineering decisions through analysis, predictive models, visualisation, and presentation of data without realization of the product or support processes’. In assembly work [18], VM is mainly used to investigate the assembly processes, the mechanical and physical characteristics of the equipment and tooling, the interrelation among different parts and factors affecting the quality based on modelling and simulation. Virtual re- ality can be used for assembly/disassembly operations. For example, can a human worker assemble a part or a com- ponent? And then can the part be disassembled for ser- vice and maintenance at latter stages? Other questions need to be addressed, too: is it “difficult” or “easy” to assem- ble/disassemble a part? How long does it take? How stressful is itin terms of ergonomics? Is there enough room for tools?.](https://figures.academia-assets.com/52463751/table_004.jpg)

![Fig. 1. Metallurgical and high temperature coatings in a gas turbine. Sometimes it is necessary to build up a worn out, damaged or mismatched component [2] for reuse instead of replacing them. The coating thickness may vary anywhere from a few microns to 2.54 mm. The build up coating needs correct dimen-](https://figures.academia-assets.com/32198363/figure_002.jpg)

![Fig. 5c. Microstructure of diamalloy 2005 coating substrate. Nanostructured wear resistant coatings provide superior hardness, toughness and wear resistance [43]. This is because the fracture toughness and hardness have inverse relation with the square root of the grain size (Hall-Petch effect) [44]. A grain size below which (typically of the order of 10 nm) the material becomes amorphous by loosing its crystalline nature is the limiting point beyond material softening takes place due to inverse Hall-Petch effect. The Hall—-Petch effect breaks down at a critical grain size below which the grains are not able to support dislocation pile ups [45]. The Hall—Petch slope becomes negative below this critical grain size. Nanoparticles cannot be successfully thermal sprayed because of their low mass and their inability to be carried (momentum which is mass multiplied by the velocity of the powder particle is less) ina moving gas stream and deposited on a substrate. In order to make use of conventional thermal spray units that are commer- cially available, nanosized particles are agglomerated with a binder followed by certain degree of sintering for making feed-](https://figures.academia-assets.com/32198363/figure_011.jpg)

![Fig. 6b. Degradation of platinum aluminide coating in service [71]. Fig. 6a. The phases present in the platinum aluminide coating on DS CM247 LC blade without prior platinum diffusion [71]](https://figures.academia-assets.com/32198363/figure_013.jpg)

![tionis positive, by twisting the blade the value of out of plane damping will decrease (but must be still positive) and the in: plane damping will receive positives values. Due to the twis' of spars, the blade will vibrate not clearly edgewise or flap- wise [5]. Fig. 3. The twisted blade with straight spar. aspect. The negative value of aerodynamic damping means that some additional energy is added to the blade during vibra- tion and the amplitude of vibration is increased. A erodynamic damping has in plane and out of plane components. Damp- ing in-plane direction will have the negative value if the blade section produce the power. If damping in out of plane direc-](https://figures.academia-assets.com/41591195/figure_002.jpg)

![BEM method is an iterative method, at the beginning the value of axial retardation coefficient a is assumed to be zero, the results of simulation (calculated a) are compared with the initial value. If their values differ the calculation is repeated with the received axial retardation coefficient as initial value. If they agree the calculation is finished. Below there are shortly presented the equations used in BEM method [2].](https://figures.academia-assets.com/41591195/figure_004.jpg)

![The applied probabilities of genetic operations were adopted on the basis of studies performed, inter alia, by the authors and presented, for instance, in Ref. [1]. a ae Optimisation calculations were done with the use of the authors’ program that implemented a modified genetic algo-](https://figures.academia-assets.com/41591195/figure_010.jpg)