In recent years, concerns about the sustainability and social responsibility (CSR) of businesses have become an increasingly high profile issue in many countries and industries, none more so than the mining industry. For mining, one... more

Sustainability strategies create many synergistic effects for SMEs working collaboratively, as well as systemic benefits for the commons. After setting forth the business case for sustainable SMEs, and considering SME sustainability... more

This study contributes to current knowledge of sustainability in textile and clothing production and consumption. When the textile and clothing industry aims to promote sustainability, the main change factors have been linked to... more

Purpose -The purpose of this paper is to act as a meticulous conceptual paper probing the contemporary view towards lean and illustrate that, despite its discernible benefits, the implementation record suffers as the prevailing opinion... more

In recent years, concerns about the sustainability and social responsibility (CSR) of businesses have become an increasingly high profile issue in many countries and industries, none more so than the mining industry. For mining, one... more

Sustainable development requires radical and systemic innovations. Such innovations can be more effectively created and studied when building on the concept of business models. This concept provides firms with a holistic framework to... more

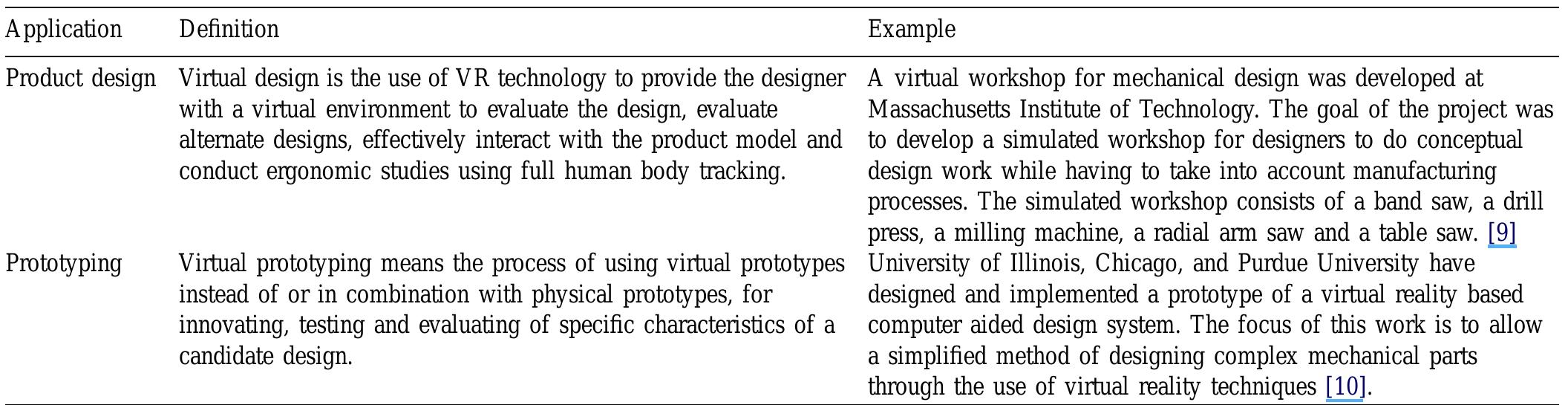

Virtual reality (VR) is a rapidly developing computer interface that strives to immerse the user completely within an experimental simulation, thereby greatly enhancing the overall impact and providing a much more intuitive link between... more

Entrepreneurship is considered a central force of economic development, as it generates growth and serves as a vehicle for innovation and change. Tourism is one of the economic sectors in which a great degree of involvement is needed by... more

What do engineering students learn in sustainability courses? The effect of the pedagogical approach

Purpose -This paper sets out to discuss the commonalities that can be found in learning outcomes (LOs) for education for sustainable development in the context of the Tbilisi and Barcelona declarations. The commonalities include systemic... more

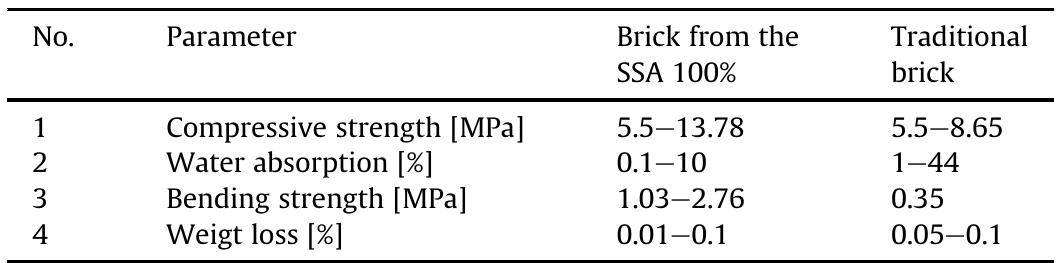

Concern over the impact of anthropogenic carbon emissions on the global climate has increased in recent years due to growth in global warming awareness. Approximately 5% of global CO 2 emissions originate from the manufacturing of cement,... more

I ndustrialization and economic development have historically been associated with man's ability to harness natural energy resources to improve his condition. Based on this definition, two industrial revolutions occurred in the 18th and... more

Introducing a new engineering product or changing an existing model involves making designs, reaching economic decisions, selecting materials, choosing manufacturing processes, and assessing its environmental impact. These activities are... more

The growing awareness regarding environmental sustainability has fully reached business reality. Consumers and companies alike are looking for alternatives to mitigate pressing environmental demands resulting from continuous population... more

An axiom that has shaped policy approaches to sustainable consumption has been that if more consumers understand the environmental consequences of their consumption patterns, through their market choices they would inevitably put pressure... more

The paper defines and clarifies basic concepts of enterprise architectures. Then an overview on architectures for enterprise integration developed since the middle of the 1980s is presented. The main part of the paper focuses on the... more

In 1966, a report published by the UK Department of Education and Science introduced the concept of tribology, which was defined as the science of interacting surfaces in relative motion. Tribology, as a "new science," studies friction,... more

Green innovation has currently been receiving a great deal of international attention because of the growing concern of consumers, governments, and the community as a whole with regard to the degradation of natural resources and... more

Photovoltaic energy has grown at an average annual rate of 60% in the last 5 years and has surpassed 1/3 of the cumulative wind energy installed capacity, and is quickly becoming an important part of the energy mix in some regions and... more

The components of a gas turbine operate in an aggressive environment where the temperature of service varies from ambient to near melting point of materials which introduce a variety of degradation on the components. Some components that... more

The manufacturing cost of WT blade is about 15-20% of wind turbine production cost. The expenses of innovations in design of blades represent the small amount of overall cost of wind turbine production. Profits coming from better... more

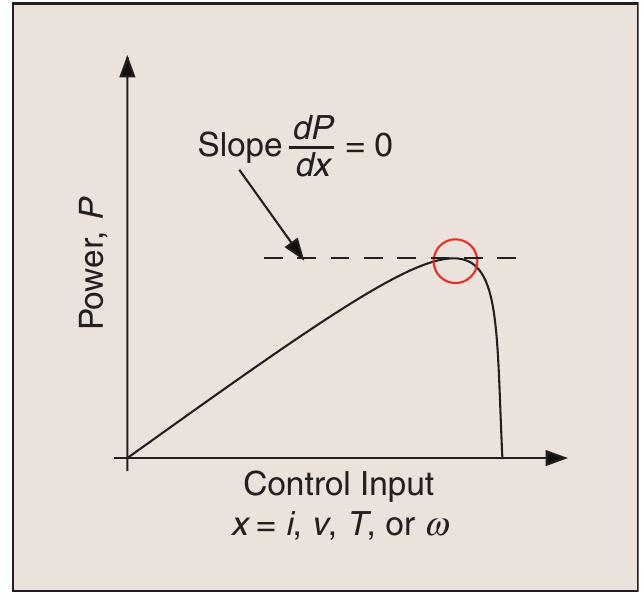

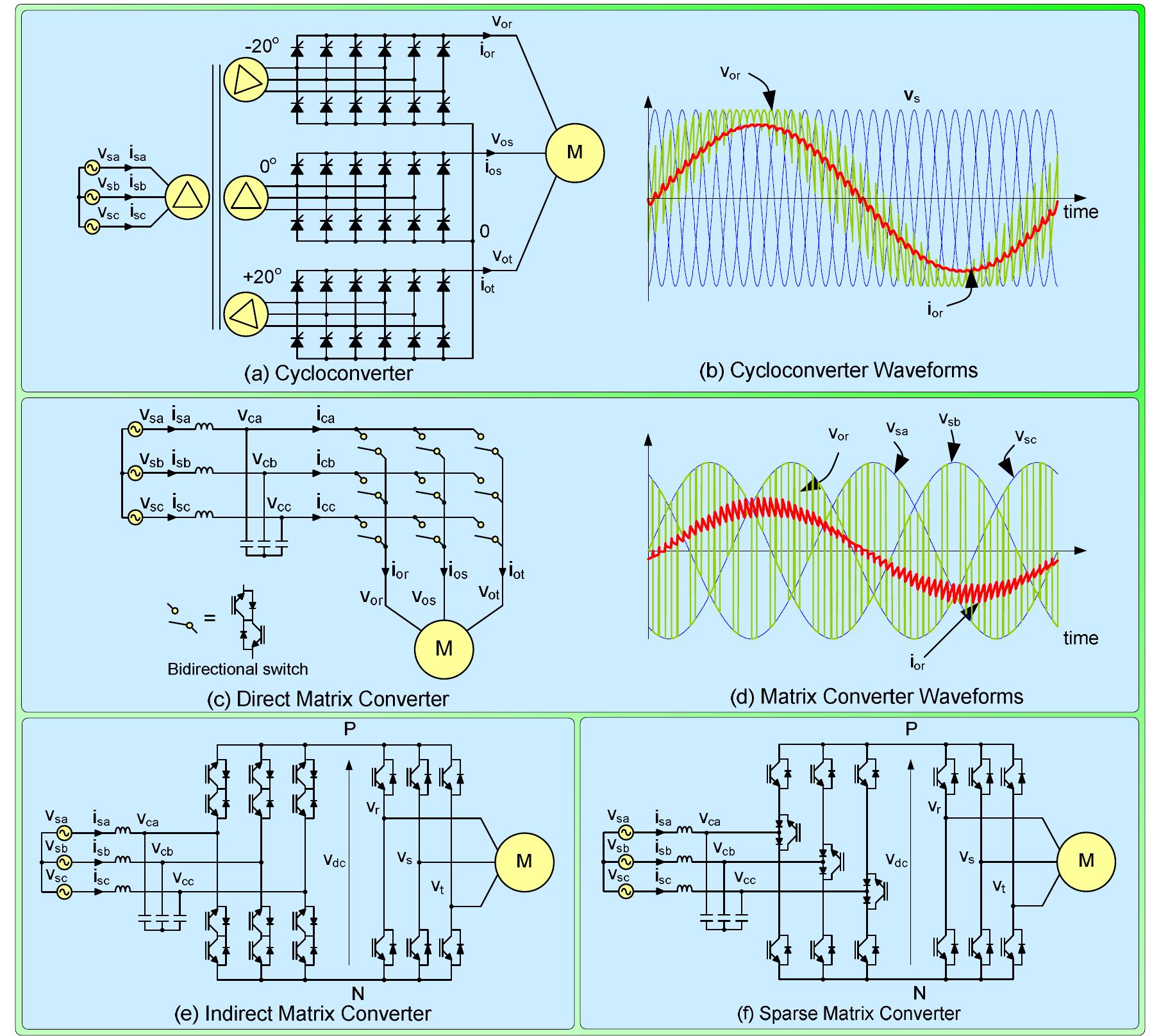

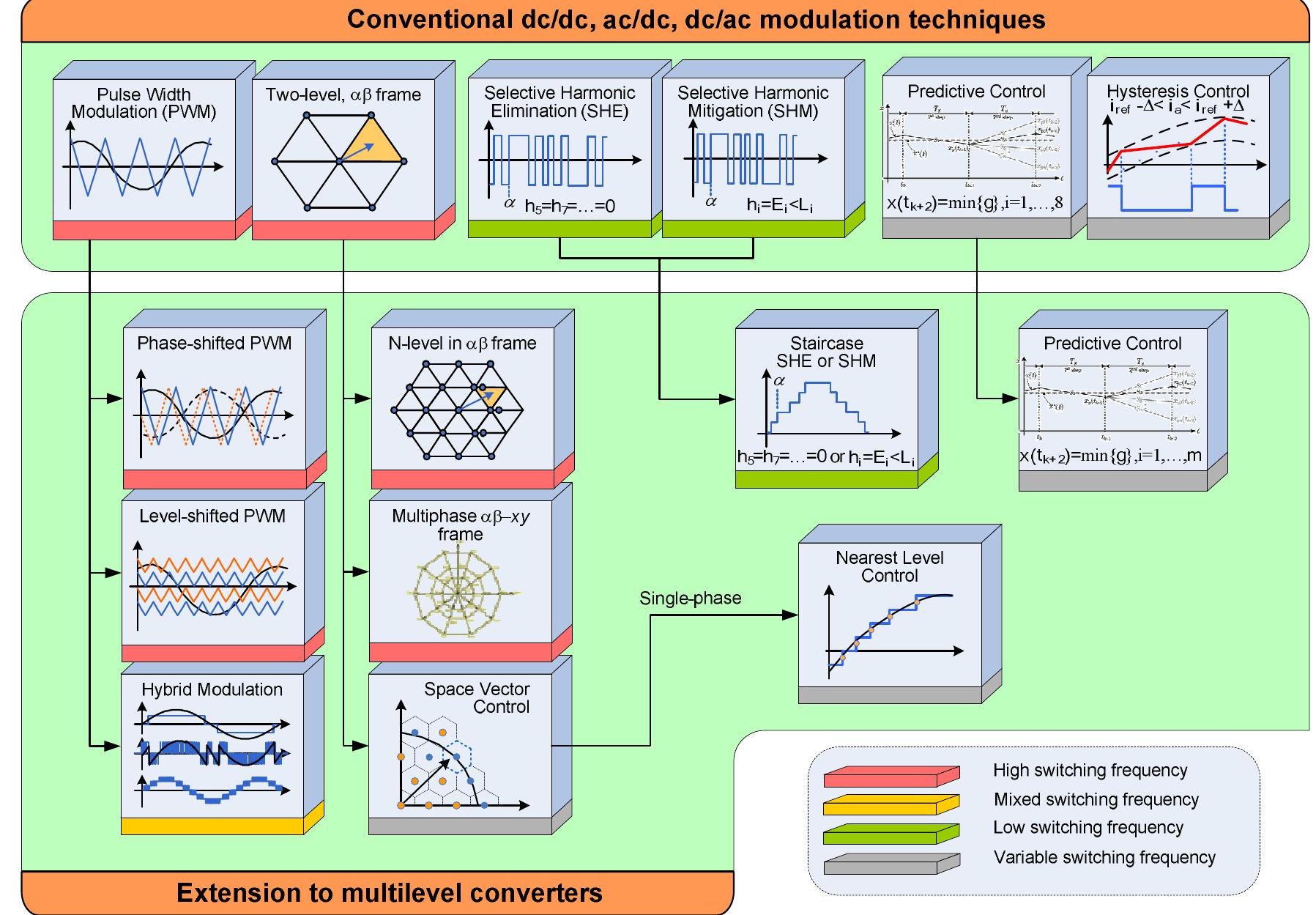

Power electronic converter-fed high performance AC drives belong to high-tech industry and are one of main factors for energy saving and productivity growth. This paper reviews present state and trends in development of key parts of... more

Production of alkaline keratinolytic protease related to various industrial applications, especially for enzyme detergents combination, was done from a selected bacterial strain Paenibacillus woosongensis TKB2. Enzyme yield was maximized... more

The common failures mechanisms of boiler components at elevated temperatures and monitoring techniques used in power plants to detect damaging or failures are generally well described in literature. Despite of different classification... more

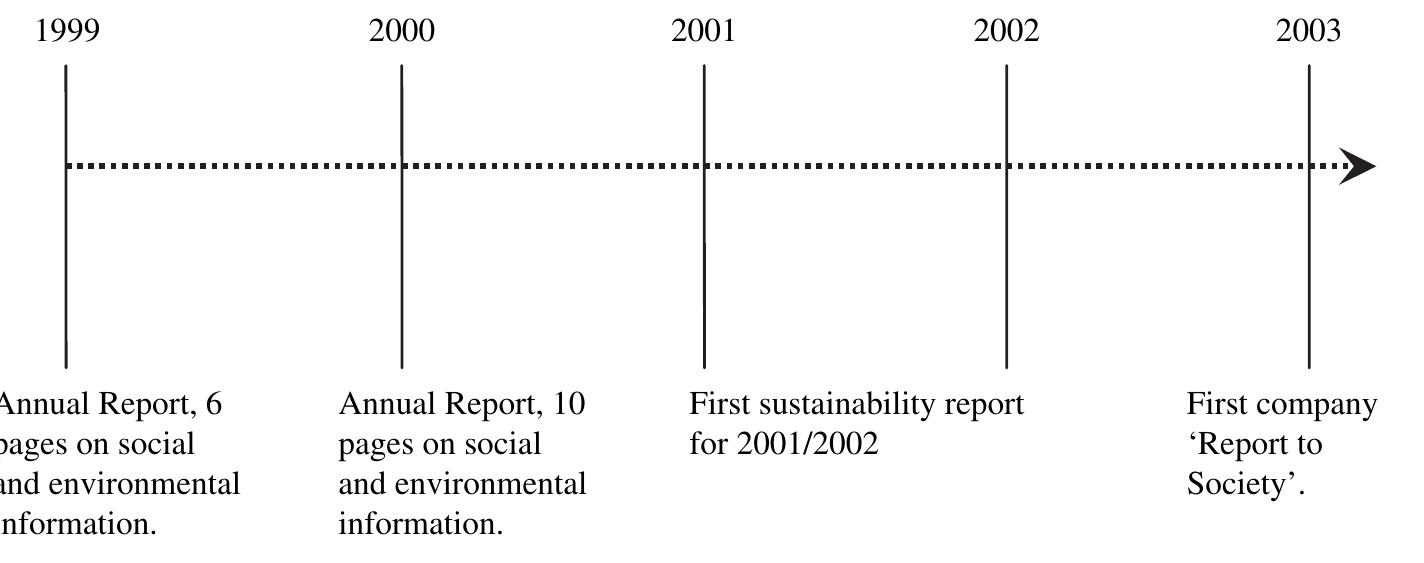

Against the background of the growing importance in corporate sustainability reporting, the Institute for Sustainable Management at the University of OAS in Aargau, North-Western Switzerland, instituted a research project in 2003. This... more

The number of tools and approaches to develop sustainability is growing rapidly. Sometimes they are presented as if they are contradictory or in competition. However, a systems approach consistent with basic principles and the... more

Rapid manufacturing using 3-D printing is a potential solution to some of the most pressing issues for humanitarian logistics. In this paper, findings are reported from a study that involved development of a new type of 3-D printer. In... more

Metal forming is not only shaping the form of a product, it is also influencing its mechanical and physical properties over its entire volume. Advanced analysis methods recently enable accurate prediction of these properties and allow for... more

The construction industry already recognises the strong business case for improving resource productivity. It is associated with circular economy system (CE), propagated by the European Union. Circular economy systems keep the added value... more

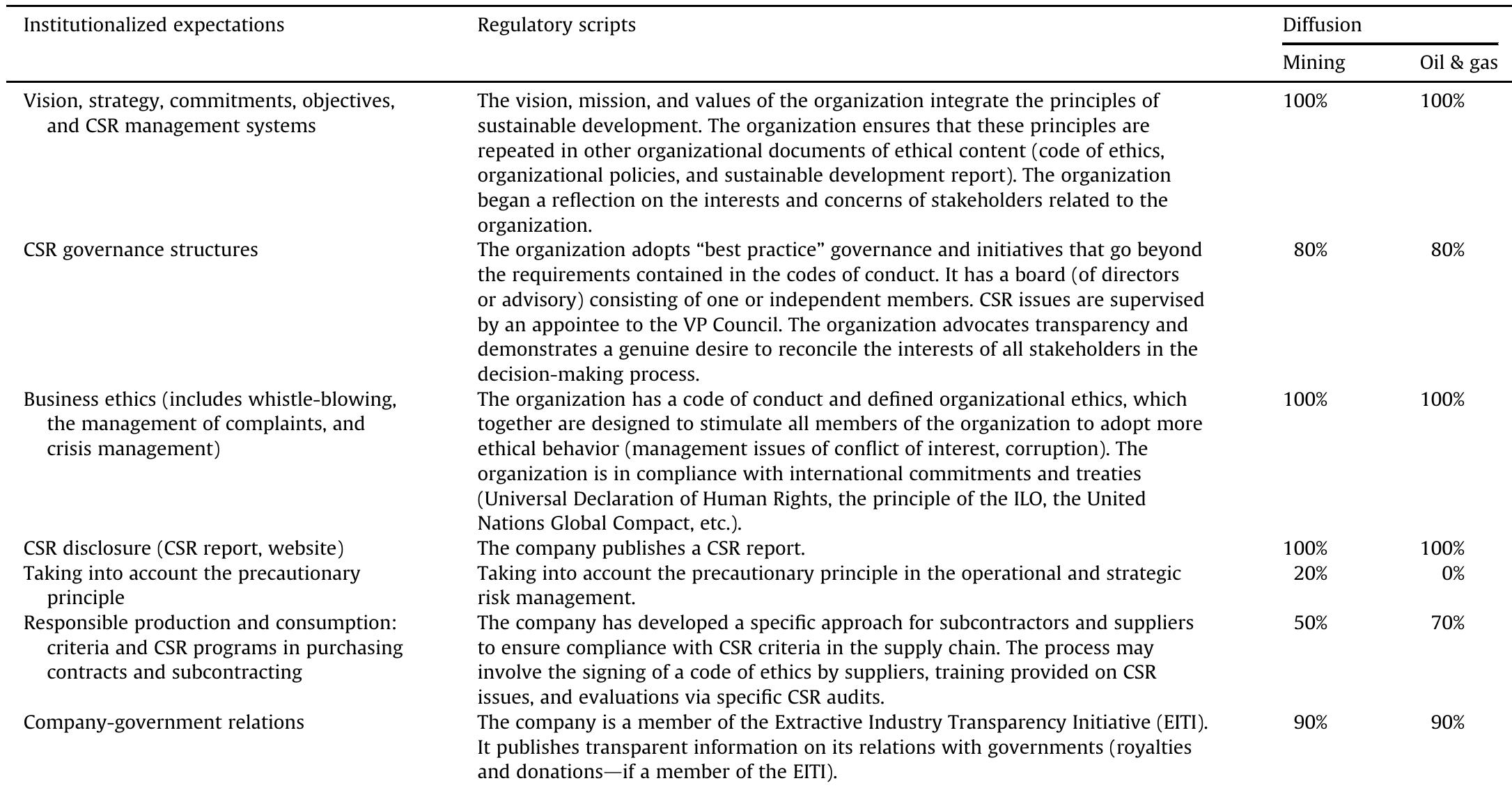

Companies in the mining and oil and gas (MOG) industries operate in diverse institutional contexts, including developed and developing countries. The companies face significant environmental and social challenges ranging from pollution to... more

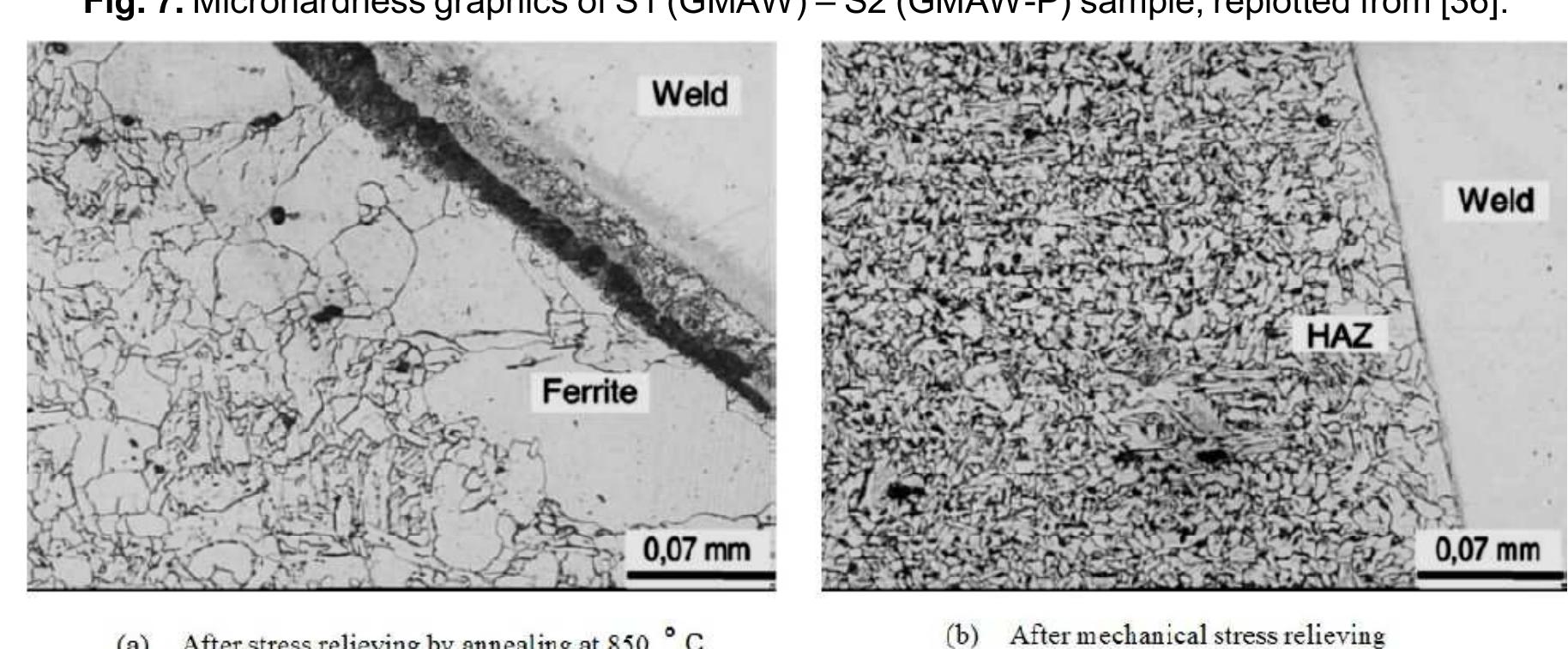

Dissimilar ferrous metal welding using advanced gas metal arc welding processes k ( & 3 c N [ P R D a b f 5R [ a R 5 a Rev. Adv. Mater. Sci.

This study examined the use of coal bottom ash (BA) from Tuncbilek Thermal Power Plant, Turkey, as an aggregate to produce aerated concrete. The BA was used as an aggregate with different replacement amounts. To determine the effect of... more

A new trend of product-service systems (PSS) that has the potential to minimise environmental impacts of both production and consumption is emerging. This article attempts to build a theoretical framework for PSS and serves as a... more

Titanium dioxide nanoparticles have been prepared by hydrolysis of titanium isopropoxide. Aqueous solution with various pH and peptizing the resultant suspension has been applied for preparation of the TiO 2 nanopowder with narrow size... more

The user has requested enhancement of the downloaded file. All in-text references underlined in blue are added to the original document and are linked to publications on ResearchGate, letting you access and read them immediately. This... more

Business Process Management Systems (BPMSs) are software platforms that support the definition, execution, and tracking of business processes. BPMSs have the ability of logging information about the business processes they support. Proper... more

![The pros and cons of electronic information provision (adapted from Elvins [41] and Scott and Jackson [42])](https://figures.academia-assets.com/31082541/table_001.jpg)

![Classification of top 10 mining companies according to reporting formats (adapted from Satterbaxter [57])](https://figures.academia-assets.com/31082541/table_004.jpg)

![Fig. 1. The Hart-Milstein matrix for assessing the value of sustainability within an organization’s strategic plan, from Hart and Milstein [4]. A review of business cases indicates that SMEs can bring skill sets to bear on disruptive opportunities quickly and more competitively than existing MNE firms [17,28,33,71]. These cases, ranging from health care and communications to apparel and manufacturing, all have similar narratives: SMEs, founded and structured using a lens of sustainability, can focus on new innovations without the dis- tractions of having to “fix” existing operations. These SMEs, focused on sustainable opportunities, do not have an existing history of “compliance only” investment and infrastructure to overcome. SMEs can invest in leading edge efforts in sustainable enterprise, without risking or dealing with entrenched expectations internally or externally to the firm. Initially, entrepreneurial firms such as Smaller firms can often develop without such competitive fric- tion and expectations. Therefore, MNEs may find that by adopting new sustainable strategies, through SMEs, they can more quickly evolve technologies and markets that are disruptive, rather than fighting through frustrating organizational conflicts. This strategy](https://figures.academia-assets.com/31208845/figure_001.jpg)

![The pros and cons of electronic information provision (adapted from Elvins [41] and Scott and Jackson [42])](https://figures.academia-assets.com/43539676/table_001.jpg)

![Classification of top 10 mining companies according to reporting formats (adapted from Satterbaxter [57])](https://figures.academia-assets.com/43539676/table_004.jpg)

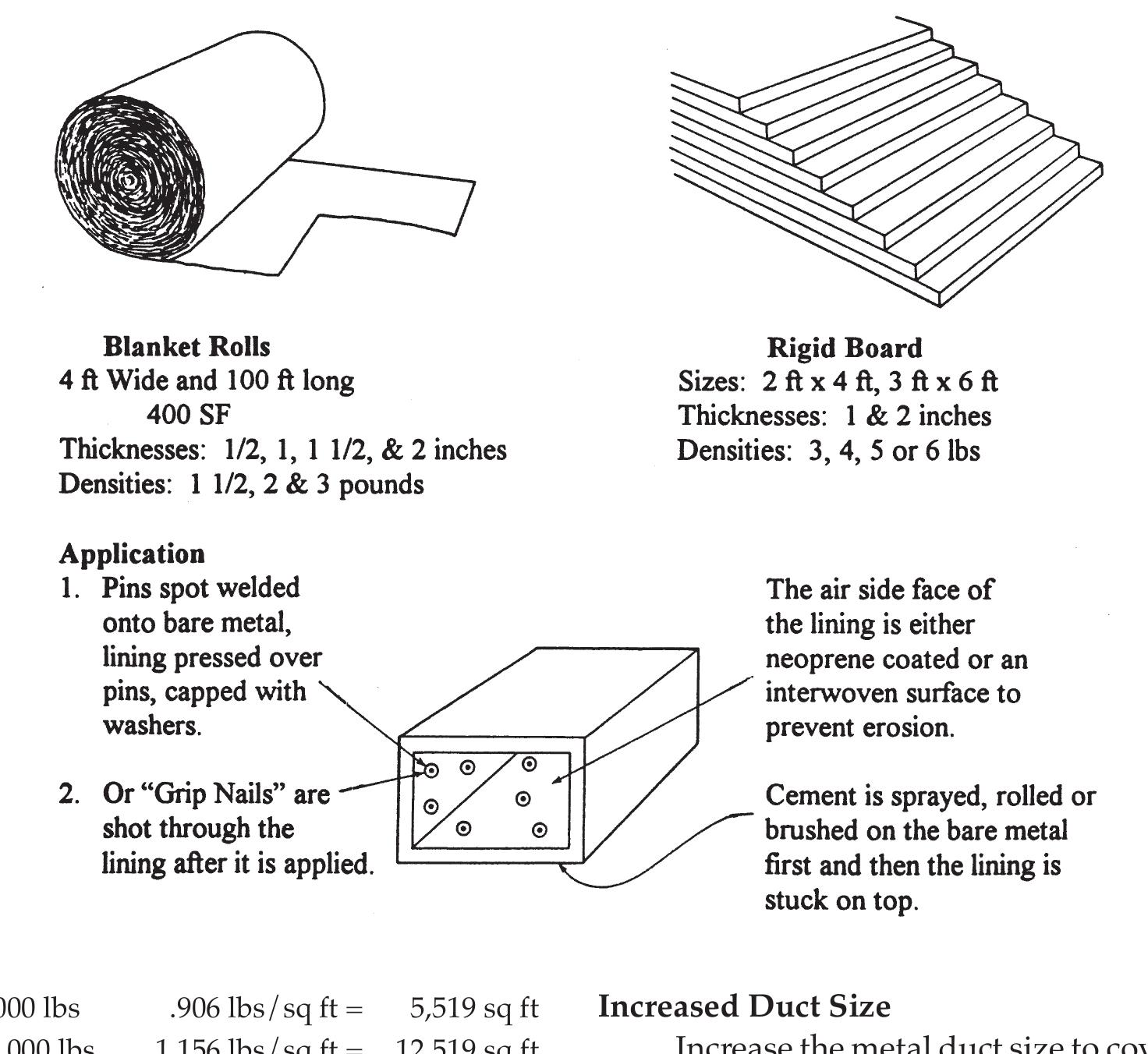

![it is becoming increasingly difficult to meet customers’ demands and to compete. The advances in virtual reality technology in the last decade have provided the impetus for applying VR to different engineering applications such as product design, modelling, shop floor controls, process sim- ulation, manufacturing planning, training, testing and veri- fication. VR holds great potential in manufacturing applica- tions to solve problems before being employed in practical manufacturing thereby preventing costly mistakes. Virtual reality not only provides an environment for visualisation in the three-dimensional environment but also to interact with the objects to improve decision making from both qualitative and quantitative perspectives [8]. The following section discusses the use of virtual reality in manufacturing applications, which include, design, prototyping, machin- ing, assembly, inspection, planning, training and simulation. Virtual reality applications in manufacturing have been classified into three groups; operations management, man- ufacturing processes, and design. A brief description of every group and its relevant subgroups will be provided in the coming sections. product in the virtual environment. At this stage, functional experimentation of mechanical sembly, etc. could be performed to evaluate the conceptual design and modifications could product, which are to be inves neering analysis, manufacturing typing should include [6]. features such as hinges, as- be made as required. Once the designers are satisfied with their design, then the de- sign could be detailed to make the necessary modifications. n the product development process, prototyping is an es- sential step. Prototypes represent important features of a tigated, evaluated, and im- proved. Virtual prototyping could be used before building the physical prototype to prove design alternatives, to do engi- planning, support manage- ment decisions, and to get feedback on a new product from prospective customers. The virtual environment for proto-](https://figures.academia-assets.com/52463751/table_002.jpg)

![summary for virtual reality benefits in manufacturing applicatior 1.2.3.2. Assembly. Virtual assembly is a key component of virtual manufacturing and is defined as: “the use of computer tools to make or “assist with” assembly-related engineering decisions through analysis, predictive models, visualisation, and presentation of data without realization of the product or support processes’. In assembly work [18], VM is mainly used to investigate the assembly processes, the mechanical and physical characteristics of the equipment and tooling, the interrelation among different parts and factors affecting the quality based on modelling and simulation. Virtual re- ality can be used for assembly/disassembly operations. For example, can a human worker assemble a part or a com- ponent? And then can the part be disassembled for ser- vice and maintenance at latter stages? Other questions need to be addressed, too: is it “difficult” or “easy” to assem- ble/disassemble a part? How long does it take? How stressful is itin terms of ergonomics? Is there enough room for tools?.](https://figures.academia-assets.com/52463751/table_004.jpg)

![Fig. 1. Framework for encouraging rural entrepreneurship [18].](https://figures.academia-assets.com/47899124/figure_001.jpg)

![Fig. 2. Overview of ‘E’ climate elements [18].](https://figures.academia-assets.com/47899124/figure_002.jpg)

![Fig. 1. Process flow diagram for the cement manufacturing process, showing energy and heat consumption or inputs, as well as gaseous and particulate emissions (adapted from Ref. [31]). Note that emissions at the preheating and kiln stages include both fugitive emissions and cement kiln dust or those particulates captured with controlled devices. Life cycle assessment (LCA) is a method of evaluation used to assess the environmental impacts of technologies from “cradle to](https://figures.academia-assets.com/48228092/figure_001.jpg)

![Fig. 3. Material flow diagram for the production of 1 ton of traditional Portland cement (adapted from Rundman [28]).](https://figures.academia-assets.com/48228092/figure_003.jpg)

![Fig. 4. Life cycle network (cradle to gate) showing the allocation of environment impact for each step of the traditional Portland cement manufacturing process. The environmental impact score by impact categories for the four different cement products is shown below in Table 4. Of primary interest is the global warming potential of the traditional cement product versus the three (3) process/product alternatives. The main greenhouse gas generated from the manufacturing cement is carbon dioxide (COz). As mentioned previously approx- imately half of the carbon released during the manufacturing of cement originates from the calcining process (driving off CO2 from limestone to form clinker) and the remaining carbon results from the burning of fuels to fire the kiln and power the other manufacturing processes. Of the cement products examined, the blended cement has the lowest global warming potential followed by cement produced when a portion of the process related carbon emissions are captured back by sequestration in CKD. The recycling of CKD back into the kiln feed has little to no effect on reducing carbon emissions compared to traditional cement. The high impact scores for heavy metals and acidification are believed to be an artifact of the types of fuels selected and the incomplete representation of chemical interactions occurring in the kiln. For instance the actual sulfur dioxide emissions (a major contributor to acid rain) are much lower than those predicted in SimaPro. The clinker and CKD serve as partial scrubbers for SO2, removing a significant portion of the sulfur oxides (greater than 70%) in the combustion gases before they are released to the atmosphere [36]. Actual fugitive emissions of SO2 equal approxi- mately 0.27 and 0.54kg per ton of clinker produced [36,18], compared to the 4.86 kg estimated by SimaPro. As for heavy metals, the lead (Pb) content of the fuels selected (i.e. fuel oil) is assumed to be the source of the high heavy metal impact score. While heavy metals are released during the burning of many of the fuels typi- cally used during the manufacturing of cement, as with sulfur dioxide (SO), metals tend to concentrate in both the cement kiln dust (primarily) and clinker [36]. Since the focus of this assessment was global warming potential or greenhouse impact, corrections](https://figures.academia-assets.com/48228092/figure_004.jpg)

![Raw material composition of clinker, the primary component of Portland cement [7]. Table 1](https://figures.academia-assets.com/48228092/table_001.jpg)

![Energy consumption by fuel type in 2000 by the United States cement industry (from Ref. [18]). kMt: thousand metric tons and ML: million liters.](https://figures.academia-assets.com/48228092/table_003.jpg)

![Meeting the global demand for en- ergy is now the key challenge to sus- tained industrialization. Furthermore, modern power distri- bution systems made abundant energy reliably available and rela- tively independent from the plant location. More than two centuries of past industrialization exploited non- renewable energy resources, how- ever, often with undesirable side effects such as pollution and other damage to the natural environment. In the second half of the 20th century, extraction of energy from nuclear processes grew in popularity, reliev- ing some demands on limited fossil fuel reserves, but at the same time, raising safety and political problems. On the other hand, network and wireless communication systems have birthed another modern eco- nomic and industrial revolution. New industries and economies based on communication services have sprung up from the widespread availability of information. Harnessing information continues to change the course of technological and social development [1]. In this article, the authors suggest that the landscape or history of indus- trialization is a full circle: from energy](https://figures.academia-assets.com/40645725/figure_001.jpg)

![FIGURE 2—A possible scenario of the future power system based on smart-grid technolo- gies, with power electronic building blocks (PEBBs) and mechanical building blocks (MEBBs) as intelligent energy conversion nodes. In the next section, a possible scenario for future power systems is explored. The requirements of energy control and information flow are exam- ples of multidisciplinary cooperations A smart grid is modeled by two concentric circles—the outer circle represents energy flow and the inner circle models information flow over communication networks. Different approaches to the management of energy flow in active grids integrating distributed power generation have been proposed [11]. One of the most interesting ideas employs energy hubs to manage multiple energy car- riers (e.g., electricity, natural gas, and district heating) [12]. Within each hub](https://figures.academia-assets.com/40645725/figure_005.jpg)

![FIGURE 3—Major ICT application domains in smart grids and their correlation with grid levels. From an application perspective, there are three major domains for ICT (Figure 3). Supervisory control and data acquisition (SCADA) is already widely used for remote monitoring and controlling of higher levels of the distribution grid [17]. This area is also well covered by advanced standards such as IEC 61850 for substation auto- mation. Active distribution grids are the core of modern smart grids and enable the integration of distributed energy sources mainly into the mid- level voltage grid. The predominant task of communication in this respect is to collect critical network parame- ters and to actively influence the dis- tributed energy generation so as to maintain overall power quality. On the lower grid levels, smart metering is the most relevant use case for ICT.](https://figures.academia-assets.com/40645725/figure_006.jpg)

![Fig. 1. Revised ENV 40003: modeling framework for enterprise integration [2].](https://figures.academia-assets.com/43942799/figure_002.jpg)

![Fig. 1. Metallurgical and high temperature coatings in a gas turbine. Sometimes it is necessary to build up a worn out, damaged or mismatched component [2] for reuse instead of replacing them. The coating thickness may vary anywhere from a few microns to 2.54 mm. The build up coating needs correct dimen-](https://figures.academia-assets.com/32198363/figure_002.jpg)

![Fig. 5c. Microstructure of diamalloy 2005 coating substrate. Nanostructured wear resistant coatings provide superior hardness, toughness and wear resistance [43]. This is because the fracture toughness and hardness have inverse relation with the square root of the grain size (Hall-Petch effect) [44]. A grain size below which (typically of the order of 10 nm) the material becomes amorphous by loosing its crystalline nature is the limiting point beyond material softening takes place due to inverse Hall-Petch effect. The Hall—-Petch effect breaks down at a critical grain size below which the grains are not able to support dislocation pile ups [45]. The Hall—Petch slope becomes negative below this critical grain size. Nanoparticles cannot be successfully thermal sprayed because of their low mass and their inability to be carried (momentum which is mass multiplied by the velocity of the powder particle is less) ina moving gas stream and deposited on a substrate. In order to make use of conventional thermal spray units that are commer- cially available, nanosized particles are agglomerated with a binder followed by certain degree of sintering for making feed-](https://figures.academia-assets.com/32198363/figure_011.jpg)

![Fig. 6b. Degradation of platinum aluminide coating in service [71]. Fig. 6a. The phases present in the platinum aluminide coating on DS CM247 LC blade without prior platinum diffusion [71]](https://figures.academia-assets.com/32198363/figure_013.jpg)

![tionis positive, by twisting the blade the value of out of plane damping will decrease (but must be still positive) and the in: plane damping will receive positives values. Due to the twis' of spars, the blade will vibrate not clearly edgewise or flap- wise [5]. Fig. 3. The twisted blade with straight spar. aspect. The negative value of aerodynamic damping means that some additional energy is added to the blade during vibra- tion and the amplitude of vibration is increased. A erodynamic damping has in plane and out of plane components. Damp- ing in-plane direction will have the negative value if the blade section produce the power. If damping in out of plane direc-](https://figures.academia-assets.com/41591195/figure_002.jpg)

![BEM method is an iterative method, at the beginning the value of axial retardation coefficient a is assumed to be zero, the results of simulation (calculated a) are compared with the initial value. If their values differ the calculation is repeated with the received axial retardation coefficient as initial value. If they agree the calculation is finished. Below there are shortly presented the equations used in BEM method [2].](https://figures.academia-assets.com/41591195/figure_004.jpg)

![The applied probabilities of genetic operations were adopted on the basis of studies performed, inter alia, by the authors and presented, for instance, in Ref. [1]. a ae Optimisation calculations were done with the use of the authors’ program that implemented a modified genetic algo-](https://figures.academia-assets.com/41591195/figure_010.jpg)

![Figure 1. Classification of the power converter applications The roots of power electronics go back to 1901 when P. C. Hewitt invented glass-bulb mercury-arc rectifier [1]. However, the present era of semiconductor power electronics started with the commercially introduced by General Electric (GE) silicon controlled rectifier (SCR), popularly called thyristor, in 1958. Next, the development continued in new semiconductor structures, materials, fabrication, etc. bringing on the market many new devices with higher power ratings and improved characteristics. Today among most common power electronic devices are: power metal oxide semiconductor field effect transistor (MOSFET) and insulated gate bipolar transistors (IGBT), and in very high power range the integrated gate-commutated thyristors (IGCT) jError! No se encuentra el origen de la referencia.]. Also, integrated intelligent power modules (IPM) are available. Today very promising, opening new era of high voltage, high frequency, and high-temperature technology are semiconductor devices based on wide-band gap silicon carbide (SiC) material.[3]. The new power semiconductor devices have always triggered the development of new converter topologies. At the beginning it started with diode and thyristor line commutated converters and continued with modern forced commutated converters controlled via pulse width modulation (PWM) methods. The list of application of power electronics is too long to list them in all. Therefore, in Figure 1, a classification of the typical applications of power electronic converters from low to high power group is given. This paper presents an overview of power converter-fed high performance AC drives in three basic parts: power converter topologies. POWER CONVERTER TOPOLOGIES IV. 1. Voltage Source Converters](https://figures.academia-assets.com/44817266/figure_001.jpg)

![Several Torque Control (TC) methods have been developed in the last 40 years. Not all of them have found wide industrial applications. Therefore, we present only the most popular strategies used commercially and some of future trends. Existing TC methods can be classified in different ways [72][73]. In this paper, the TC methods are presented in two main groups: linear and nonlinear controllers. The discussed generic TC methods are presented for the induction motor drives; however, they can be easily expanded for control of permanent magnet synchronous motors (PMSM) with sinusoidal electromotor force (EMF) and currents.](https://figures.academia-assets.com/44817266/figure_006.jpg)

![controller is applied and its output produces an increment in the torque angle, Ady (see vector diagram in Figure 9) [80][81]. Assuming that the rotor and flux magnitudes are approximately equal, the torque is controlled only by changing the torque angle, dw, which corresponds o the increment of the stator flux vector AW;. The commanded stator flux vector is calculated by addition of the estimated flux position ys; and change of he torque angle Ady. Its value is compared with the estimated flux and the stator flux error AW, is used directly for calculation of VSI switching states in he FVM block [82][83]. Thanks to internal stator flux loop used for calculation of AW, in flux pulse width modulator, the flux PI controller of Figure 8 is eliminated.](https://figures.academia-assets.com/44817266/figure_009.jpg)

![As reported in the works by G. Papafotiou et. al. (see in [86][87]) by using a long output horizon predictive DTC, the average switching frequency, and as consequence also inverter switching losses, has been reduced 16,5% with respect to the classical DTC used by ABB while maintaining the same control quality of the motor torque, magnitude of stator flux and 3-level inverter’s neutral point voltage. This illustrates a very high improvement potential of the MPC.](https://figures.academia-assets.com/44817266/figure_012.jpg)

![Figure 15. Flux vector observer based on measured Vs, |,, Qn with compensation signal calculated from measured /, and estimated /,’ stator current vectors [85][95] between the two models is defined by design of the PI controller which generates compensation voltage Ucomp. Finally, in Figure 15, an flux vector observer based on measured stator voltage Vs, current I,, and mechanical speed Q, with compensation signal calculated from measured |, and estimated |,’ stator current vectors is shown. In this observer the motor model is fed with current vector estimated from the stator and rotor flux. The measured stator current is delivered only to Pl controller for calculation the compensation voltage Ucomp. Therefore, the model can be easily used for testing and investigation. With mechanical motion sensor it operates well at zero speed [85][95].](https://figures.academia-assets.com/44817266/figure_015.jpg)

![Short term overheating is characterized with a thin-lipped longitudinal rupture, iccompanied by noticeable tube bulging, which creates the large fish-mouth appearance, ‘ig. 2 [7]. Generally, all kinds of tubes, which carry water or steam and are exposed to 1igh operating temperatures are susceptible to this type of failure. The more serious uptures occur at tube metal operating temperatures well above the oxidation limits of the naterial but typically above the eutectoid transformation temperature 727°C. Peak metal yperating temperatures above the eutectoid transformation temperature can be estimated yy the amount of bainite or martensite mixed with ferrite in the metal microstructure at he failure origin. Short-term failure can be caused by low water level, partial or complete luggage of tubes, rapid start-ups, excessive load swings and excessive heat input [8]. Creep is high temperature damage mechanisms which includes time-dependent deformation and high temperature creep cracking. In the other words creep damage is the result of permanent plastic deformation at elevated temperatures and at stresses much less than the high temperature yield stress. Microstructural damage is detected by the presence of creep voids at the grain boundaries which have tendency to coalescence during the time and form a crack. Cracks generally propagate in an intercrystalline manner in components that fail over an extended time. These include boiler superheater and other components operating at high temperature.](https://figures.academia-assets.com/32333592/figure_002.jpg)

![Long-term overheating, Fig.4., [13] usually occurs in superheaters, reheaters and waterwalls as a result of gradual accumulation of deposits or scale, partially restricted steam or water flow, excessive heat input from burners or undesired channeling of fireside gases. Horizontal or inclined tubes subjected to steam blanketing are also prone to long-term overheating failures. Tube metal operating temperatures above 454 °C, or slightly above the oxidation limits of the tube steels, can lead to blistering, tube bulging or thick-lipped creep rupture failures [8]. Long-term failures by creep damage can occur with little or no detectable change: in the tube wall thickness. Microstructural examination is a very appropriate method o: confirming long-term overheating. The cementite platelets in the pearlite of steels will thermally decompose to spheroidized carbide. Continued decomposition will result ir total degradation to graphite plus ferrite, or graphitization [8,9]. Microstructural degradation is a damage mechanism that can lead to failure by](https://figures.academia-assets.com/32333592/figure_003.jpg)

![Figure 3. Neubauer's classification of creep damage based o: replicas observation and action to be taken [12] Based on the distribution of creep voids and microcracks observed by in situ metallography, Neubauer and Wedel [12] have been made a classification of creep damage in steam generators illustrated schematically in Fig. 3. However, as has been shown subsequently that the method is not reliable for CrMo steels, at least, as apparent voids may be developed during the polishing and etching sequence [9].](https://figures.academia-assets.com/32333592/figure_004.jpg)

![damage, because the two mechanisms are closely bound together and, indeed, are difficult to separate [9]. It has been already emphesized that Cr-Mo steels that are liable to fail by creep in a short time may decompose to spheroidized carbides but little, if any, void formation, Fig. 5. The formation of voids appears, in many cases, to be a very local phenomenon occurring very close to the time of fracture. Fatigue, involving repeated stressing, can lead to failure independently of temperature level. In components operating at high temperature it often arises through temperature changes that can lead to cyclic thermal stresses. The final result of repeating thermal stressing is appearance of thermal fatigue cracking, Fig.6. The cracks tends to develop in areas of high constraint which may arise because of different causes, 1.e because of local creep deformation.](https://figures.academia-assets.com/32333592/figure_005.jpg)

![Figure 7. Erosion at elevated temperature [15] If the hard particles are present in gas flow erosion can occur in high temperature components, Fig.7. This is a common situation in coal-fired power plants in which erosion by fly-ash can lead to tube thinning and failure in economizers and reheaters. Sootblower erosion can produce thinning in superheaters and reheaters in those tubes that are in the paths of the blowers.](https://figures.academia-assets.com/32333592/figure_006.jpg)

![shallow corrosion pits - gouges without any scalling were observed, Fig. 20c [13,22]. Microstructure in the middle of the sample 2 cross sections was also ferrite- pearlite, with the presence of completely degradated pearlite. Also, a distinctly banded structure with non-homogenous distribution of very fine elongated MnS inclusion was visible, Fig. 21a. Complete decarburization (pure ferrite), with macro crack along the boundaries and many discontinuous intergranular micro cracks were observed closer to the inner side of sample 2, Fig. 21b. Observed decarburization as well as the degradation of pearlite microconstituent indicate that the hydrogen penetration occurred through the tube wall. Many discontinuous, intergranular cracks and fissures are the result of great pressure effect of methane molecules or molecular hydrogen precipitated along the ferrite grain boundaries during high temperature tube metal hydrogen attack.](https://figures.academia-assets.com/32333592/figure_018.jpg)

![ee This process will cause dissolved or suspended solids to begin to be deposited just downstream of the flow disruption and on the hot side of the tube, Fig. 23-3. In thick porous deposit, process of wick boiling of fluid further increased the concetration of acid components within the boundary layer defective magnetite-porous deposit due to hydrolysis of salts and tube metal thermal cycling. In deposit area, local pH value drops significantly due to concetration of acidic contaminant. Just like in the case of sample | at the sites of local destruction of magnetite resulting from the flow-assisted corrosion, thermal cycling and its chemical decomposition during reaction with the hydrolysis products [3], hydrogen is formed during steam-water corrosion of metal.](https://figures.academia-assets.com/32333592/figure_020.jpg)

![In the following section, a number of concepts and associated institutions will be related to the model presented in section 1. All of those institutions are work- ing with sustainability as the ultimate goal, and have elaborated working programs that take a systems per- spective of the kind presented in the model into account. However, their “entry points” into the model vary. This means that each has its distinct primary focus (highlighted in the respective figures, see below) from which other aspects of sustainability have been elabor- ated as secondary consequences to the primary focus. This is important to recognize in order to avoid misun- derstandings of the presentation. Differences in primary focus should lead, almost per definition, to some important differences in perspectives and experiences. When the different tools are considered, this potential synergy ought to be utilized in conscientious and deliber- ate ways, rather than being perceived solely as alterna- tives, or even “competitive” alternatives. This process has led to the development of The Natu- ral Step Framework TNSF [for references, see 10] for decision-making. It is designed for qualitative problem analysis, community building, and for the development of investment-programs in business corporations and municipalities. Its primary focus is on a comprehensive definition of level 2 in the presented model, resulting in the development of the system conditions, and on back- casting and other essential elements for strategic plan- ning in level 3 to comply with level 2 (see figure below). This intellectual approach is dependent on tools developed by others to cover the other aspects of the model. This includes more quantitative assessments of the objective of meeting the system conditions (as pro- vided by other institutions like the Factor 10 Institute, see below), and various tools to monitor the transition, for instance tools for management like ISO 14001 and for indication of progress such as LCA and the Factor concept (level 5). Furthermore, since the whole idea of TNS is to develop and disseminate a framework to guide](https://figures.academia-assets.com/46523843/figure_002.jpg)

![Ecological Footprinting (EF) [3] is a way of “bench- marking” all dematerializations under the system con- ditions (level 2 in the model). One of the major differ- ences to Factor 10 is that, with Ecological Footprinting, the outcomes of various activities in society are not determined by factors (i.e. incremental units related directly to the specific materials or material flows). The outcomes are instead measured and aggregated into units of area, i.e. as a reduction or an increase in the ecological area needed to support the activities. This is then related to an estimation of the total life sustaining area of the a a Efforts have also been done to relate the material intensity to the desired utility, MIPS (material intensity](https://figures.academia-assets.com/46523843/figure_003.jpg)

![and not just arbitrarily chosen data on emissions and energy use [37]. sustainable technology up to a viable product in the mar- ket is an essential consideration in the approach of SDT. STD focuses on some well known aspects of sus- tainability as the primary objectives of planning, and like TNSF, it also puts primary focus on the relation between the objective of planning on one hand (sustainability), and principles for the process to reaching the objectives on the other. More specifically [41]:](https://figures.academia-assets.com/46523843/figure_005.jpg)

![Natural Capitalism [9] attempts to define and describe means to connect human institutions including business within the flow of natural cycles including ecosystem services. To do so it is necessary to integrate all relevant aspects of society into an economic framework used for decision-making, particularly those aspects that are becoming increasingly scarce, or are at increasing risk. Hence, our “global commons” — the well-being of glo- bal ecosystems and the long term quality of life of all people — must be integrated into any comprehensive economic model. Such an economic model recognizes the critical relationship between the pursuit of human productivity, and thus higher income, and the greater use of natural capital. Natural capital includes not only the resources demanded by business and society, but also includes the flow of services that flow from ecosystems that are not monetized or valued. Natural Capitalism describes a set of fundamental assumptions necessary for this integration of economy, ecology and societal demands. These include viewing the economy as a sub- set of the global environment; future economic growth will be limited by natural capital rather than human- made capital; radical increases in resource productivity Because of UNEP’s central position in Society’s inter- national policy making, there are some major differences between Cleaner Production, and the other institutions presented in this survey. As demonstrated by the launch of the International Cleaner Production Declaration [44], the Cleaner Production Programme objective is to cata- lyse, in all parts of the world, Cleaner Production activi-](https://figures.academia-assets.com/46523843/figure_007.jpg)

![Fig. 1. Schaeffler constitution diagram and prob- lems with welding dissimilar metals, stainless steel, and carbon steel, replotted from [19].](https://figures.academia-assets.com/42694718/figure_001.jpg)

![In industry it is often necessary to use non-stain- less steel in places where oxidation is not the pri- The mechanical properties of DMW joints regarc the critical factors of load ability and safety war. ranty. In this regard, E. Lertora et al. [21] highlightec the use of a welding robot in a mass productior setting. The enhanced process applied was a su: per-imposition metal active gas welding process (SP-MAG), which provided stable filler material trans: fer, based on adaptive waveform control. The stud) investigated dissimilar metals welds with S355 (EN 10025) steel and DP600 HSS (EN 10338). It was found that the process demonstrated the ability tc produce a dissimilar weld with adequate structura characteristics. Fig. 2 shows the hardness profile with the absence of a softening area. Pouranvar [22] found in fusion resistance spot welding of simi: lar and dissimilar high-strength low-alloy stee (HSLA) and low-carbon steel (LCS) that the micro: structure and hardness of the fusion zone (FZ) were governed by the carbon content and alloy level o the FZ. In the particular case of dissimilar HSLA LCS combinations, FZ chemical composition is af. fected by the mixing of both steels. Increasingl) harder microstructures were observed as the car. bon equivalent of the FZ increased. The mechanica performance of the joints combination revealed tha the peak load of HSLA/LCS was similar to LCS, LCS. Both investigations show that proper weldinc heat input control and matching the electrode tc minimize carbon migration can improve weld chemi cal and mechanical properties. 4.1. Other than stainless steel combinations](https://figures.academia-assets.com/42694718/figure_002.jpg)

![Although the combination of mild steel and car- bon steel can provide high rupture energy and bear- ing quality, their weldability poses a challenge be- cause of the chemical composition difference. Mir Sadat et al. [23] evaluated the mechanical proper- ties of the welded joint between dissimilar metals, mild steel IS 2062 (S275 JR according to EN 10025), carbon steel IS 45 C8 (C45E according to EN 8), bearing quality steel IS 103 Cr1 (EN-31), and car- bon steel IS C 55 in the pairs IS 2602 and IS 45 C8, IS 2602 and IS 103 Cr1, as well as IS C 55 and IS 103 Cr1, and the effect of process parameters. When comparing the hardness of the parent metal, it was shown that the slight variation of alloying elements did not result in considerable physical changes for IS602, even though a significant change occurred in the mechanical properties. In addition, Monika et al. [24] investigated the effect of the heat input on the mechanical properties of GMAW welded two dissimilar joints, |S2062-IS 45 C8 and IS2062-1S103 Cr 1. It was observed that as the heat input de- creases, there is an increase in the tensile strength In order to combine low weight and higher tough- ness, high-strength steels are widely used in in- dustry such as pressure vessel construction be- cause of their good weldability and formability. They are, however, very sensitive to welding heat input and weld diffusion. Mohandas et al. [25] studied the heat affected zone softening in high-strength low- alloy steels. The effect of the chemistry of the steel and the welding processes SMAW, GTAW, and GMAW were investigated. The extent and degree of softening have been observed to be maximum in GTAW and GMAW, which are high heat input pro- cesses. Post-weld heat treatment in the austenite region eliminated the softened zone. It is possible to achieve successful DMW with HSLA steels if proper welding procedures are followed. Ranjbarnodeh et al. [26] carried out an investigation on the influence of welding parameters on residual stresses in dissimilar HSLA steels welds. A series of dissimilar steels joints based on the S6OOMC](https://figures.academia-assets.com/42694718/figure_003.jpg)

![Fig. 3. Tensile strength for IS 2062 and IS 45 C8 joint at different heat inputs, replotted from [24].](https://figures.academia-assets.com/42694718/figure_004.jpg)

![Fig. 6. Micrography of the weld after immersion for 30 days in artificial deep water, replotted from [35].](https://figures.academia-assets.com/42694718/figure_006.jpg)

![Fig. 8. Microstructure of the 18G2A/1H18N10T steel joints after stress relieving, replotted from [37].](https://figures.academia-assets.com/42694718/figure_007.jpg)

![Fig. 9. Micrograph of dissimilar weld, (a) HAZ microstructure, austenitic side (6) HAZ microstructure, duplex steel side, replotted from [14].](https://figures.academia-assets.com/42694718/figure_010.jpg)

![Fig. 10. The 6-ferrite content of the fusion zones at various welding passes during multi-pass welding, replotted from [48].](https://figures.academia-assets.com/42694718/figure_011.jpg)

![Fig. 3. A comparison of tool wear between TiAl and TiAIN + cBN top layer coated cemented carbide cutting inserts for different cutting speeds [99].](https://figures.academia-assets.com/40605441/figure_003.jpg)

![Fig. 4. Cross-section of ESC deposited CBN, pores in the cBN layer and cross section of cBN-TiN coating [92]. Due to its extreme hardness and resistance to wear, diamond is the ideal coating material for cutting tools, designed for “difficult-](https://figures.academia-assets.com/40605441/figure_004.jpg)

![Fig. 6. Microstructure of Ti4gAls4N coating and nanostructured supernitride (SNrr) one [51].](https://figures.academia-assets.com/40605441/figure_005.jpg)

![Fig. 5. Phase diagram of the metastable system TiN-AIN [51].](https://figures.academia-assets.com/40605441/figure_006.jpg)

![Fig. 7. Cutting performance of the applied coatings in milling 42CrMo4-hardenedc steel [51].](https://figures.academia-assets.com/40605441/figure_007.jpg)

![Fig. 8. Surface structure of micro- (left) and nanocrystalline (right) CVD-diamond layer [5].](https://figures.academia-assets.com/40605441/figure_008.jpg)

![Fig. 9. Flank wear in machining Al-20 wt% SiC composite [89]. The comparison of the lifetime of coated tapping tools is illustrated in Fig. 12. At the standard machining rate of 25 m/min the performance of the nanocomposites is only a little better than the best TiAICN coating and about two-times better than the TiCN](https://figures.academia-assets.com/40605441/figure_009.jpg)

![Fig. 13. Comparison of coatings on drills made of cemented carbide (drilling GGG40) [182]. Fig. 12. Comparison of the lifetime of tools for dry tapping [182].](https://figures.academia-assets.com/40605441/figure_010.jpg)

![Fig. 11. Influence of nanocomposite structure on spinodal segregation [36,86].](https://figures.academia-assets.com/40605441/figure_012.jpg)

![Fig. 19. Radial bearing ring with DLC force sensor structures (for details see [16]).](https://figures.academia-assets.com/40605441/figure_019.jpg)

![Fig. 20. Strategies for sun-control windshield manufacture, e.g. coating on glass or lamination of coated PET (left) and layout of double silver sun-control coatings (right) [56].](https://figures.academia-assets.com/40605441/figure_020.jpg)

![Fig. 21. Optical spectra of uncoated, tinted sun-control glass and double silver coated sun control glass [55]. The sun spectrum for air mass 1.5 is also shown. Another important field of application is the control of surface energy in order to achieve water repellant easy-to-clean layers without droplet formation during rainy weather. Organic hydro-](https://figures.academia-assets.com/40605441/figure_021.jpg)

![Fig. 22. Self-regenerating coating for long term hydrophobic coating based on nanostructured surface which is covered with a hydrophobic agent supplied by the underlying replenishment layer [142].](https://figures.academia-assets.com/40605441/figure_022.jpg)

![Fig. 1. XRD patterns for TiO» particles obtained from different pH solutions and dried at 100°C for 3h. level of the solution is 2, a homogenous suspension of fine par- ticles is formed. The crystallite size of the particles has been estimated from the Debye-Scherrer’s equation using the XRD line broadening as follows [32]:](https://figures.academia-assets.com/47189204/figure_001.jpg)

![Fig. 2. Crystalline size variation of prepared powders at different pH. where s is the crystallite size, 4 the wavelength of the X-ray radiation (Cu Ka=0.15406 nm), k a constant taken as 0.94, 0 the diffraction angle and B is the line width at half maximum height. The (1 0 1) plane diffraction peak is used for anatase and (1 10) peak for rutile. Fig. 2 shows the crystalline size of as- prepared TiOz nanoparticles in the different pH. As it can be found from Fig. 2 the smallest crystallites have been obtained from the hydrolysis of TTIP in the acidic solution (pH 2) and the dried powder at 100°C. Fig. 3, shows the XRD pattern of the prepared powder from acidic solution (pH 2) and calcined at various temperatures in atmospheric condition for 2h. It can be found that all samples are crystalline and the dried powder at 100°C has anatase phase. It shows that the control of deox- olation process by initial water concentration and peptization could accelerate the anatase crystallization and shift it to tem- peratures lower than even 100°C. The temperature observed in our result is much lower than that achieved by others [33]. The effect of calcination temperatures on the crystalline size of TiO2 was shown in Figs. 4 and 5. When the temperature has been](https://figures.academia-assets.com/47189204/figure_002.jpg)

![Fig. 5. SEM micrographs of dried powders at 100°C: (a) pH 2; (b) pH 9. raised to 200 and then 400 °C, the size of formed crystallites has increased which could be attributed to the thermally promoted crystallite growth. The size of anatase crysta lites increases from 7.6 to 38.7 nm when calcination temperature has been elevated to 600°C. At 600 °C, apart from anatase, sh arp rutile peaks was also observed in the XRD result. The formed rutile showed quite different behavior having larger size than the remained anatase particles. This, in fact, reveals that nucleation and growth of rutile phase would have been initiated at tem perature somewhere from 400 to 600°C [34]. Anatase to rutile transformation tem- perature is shifted to the very low temperature level for nanosize crystallites because of the high surface energy of the particles. It is observed that, in the higher calcination temperatures, the larger particle size with spherical morphology is obtained. For the sample calcined at 400°C (Fig. 7), the particle size is almost 100 nm. Shape and morphology is clearly observed in the SEM micrographs of the samples calcined at that temperature. From the SEM photographs of samples prepared under different pH values, it has been revealed that the spherical morphology was a specification of the prepared powder under acidic solu- tion of pH 2 and it was not seen in other samples. The TEM image and the select-area electron diffraction (SAED) pattern](https://figures.academia-assets.com/47189204/figure_005.jpg)

![Fig. 2. Examples of growing total consumption. Source: Ref. [7]. other and shape the development of society. Many studies fo- cus on why people buy goods, how products satisfy consumer preferences and how products become symbols of meaning in society. Sociology proposes that consumer choice is influenced by functional, conditional, social, emotional and epistemic values of products. Changes of values are often explained from evolutionary and generational perspectives. An important line of sociological research analyses institutional influences, such as family, religion and the educational system. Social Sociological studies focus on how various institutions in society affect consumption patterns and investigate the forma- tion processes around consumption practices. The major themes studied are the influences of social culture, social class and family, ethnic and religious groups. Social institutions, social groups, ideologies and behaviours mutually reinforce each a rational response to price signals being influenced by differ- ent internal and external drivers induced by human psychol- ogy, social norms and institutional settings.](https://figures.academia-assets.com/51021475/figure_002.jpg)

![Fig. 1. Total and per capita energy consumption in 1995. Source: Ref. [5].](https://figures.academia-assets.com/51021475/figure_003.jpg)

![Fig. 3. Thresholds of happiness in different countries. Source: Ref. [8].](https://figures.academia-assets.com/51021475/figure_005.jpg)

![Global annual expenditures on products and investments needed for different social goals Source: Ref. [6].](https://figures.academia-assets.com/51021475/table_001.jpg)

![Fig. 10. Screen shot from Business Process Cockpit: process focus and taxonomy perspective. started in a certain time window) or to specific resource values (e.g., analyze only instances in which a specific resource was involved). As an example, Fig. 10 shows the distribution of process instances among the categories of a duration taxonomy. The duration taxonomy has four categories: fast (defined as processes lasting less than 5 days), acceptable (between 5 and 10 days), slow (between 10 and 15 days) and very slow (more than 15 days). More details on the BPI Cockpit can be found in [7]. resource values (e.g., analyze only instances in which](https://figures.academia-assets.com/50252680/figure_009.jpg)