The Welding Handbook

Abstract

Notice: All welding is carried out on the welder's own risk and account. Welding should be executed by a qualified and experienced welder and adequate safety measures should always be adhered to. The information and guidelines in this Welding Handbook are based on general information and knowledge at hand and are believed to be accurate and reliable, but the information and guidelines are not to be taken as a guarantee or warranty for a special purpose. The information and guidelines are provided to the welder solely for his own consideration, and Wilhelmsen Ships Service AS assumes no legal responsibility or liability for eventual damages and/or losses should the information and/or guidelines turn out to be incorrect or un-suitable. Wilhelmsen Ships Service AS is not liable for any loss or damages whatsoever and howsoever arising which is due to force majeure, other events beyond the reasonable control of Wilhelmsen Ships Service AS or events that could not reasonably be foreseen by Wilhelmsen Ships Service AS when this Welding Handbook was made. Wilhelmsen Ships Service AS is in no event liable for indirect, incidental or consequential damages or losses, including damages for loss of profits, resulting from lack of conformity, including but not limited to loss resulting from goods or software not working when connected to other goods/software or for any related cause thereto. Wilhelmsen Ships Service AS's liability shall in any event not exceed the total purchase price of theWilhelmsen Ships Service AS goods used during the welding operations. These conditions are automatically accepted by anybody using the information and guidelines in this Welding Handbook.

References (47)

- Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

- Types of electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Storing and re-drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Classification and approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Welding positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- GPO-302 N General Purpose Electrode For Mild Steel . . . . . .

- GPR-300H High Recovery Electrode for Mild Steel . . . . . . . . .

- SPECIAL-303 N Double Coated Electrode for Mild and Ship Quality Steel . . . . . . . . . . . . . . . . . . . . . . . .

- LHH-314 H High Recovery Low Hydrogen Electrode for Ship Quality Steel . . . . . . . . . . . . . . . . . . . . . . . . .

- LHV-316 N Vertical Down Welding Low Hydrogen Electrode for Ship Quality Steel . . . . . . . . . . . . . . . .

- LHT-318 N Electrode for High Temperature Steel . . . . . . . . . .

- LHL-319 N Electrode for Low Temperature Steel . . . . . . . . . . .

- LHR-320 N Electrode for Weathering Steel . . . . . . . . . . . . . . . .

- TENSILE-328 N Electrode for Difficult-to-Weld Steel. . . . . . . . . . . . IMPACT-329 S Electrode for Heat Resistant Overlays . . . . . . . . . . WEARMAX-327 Electrode for Joining & Wear Resistant Overlays 18/8-321 N Electrode for Stainless Steel . . . . . . . . . . . . . . . . . . 23/14-322 N Electrode for Stainless Steel . . . . . . . . . . . . . . . . . .

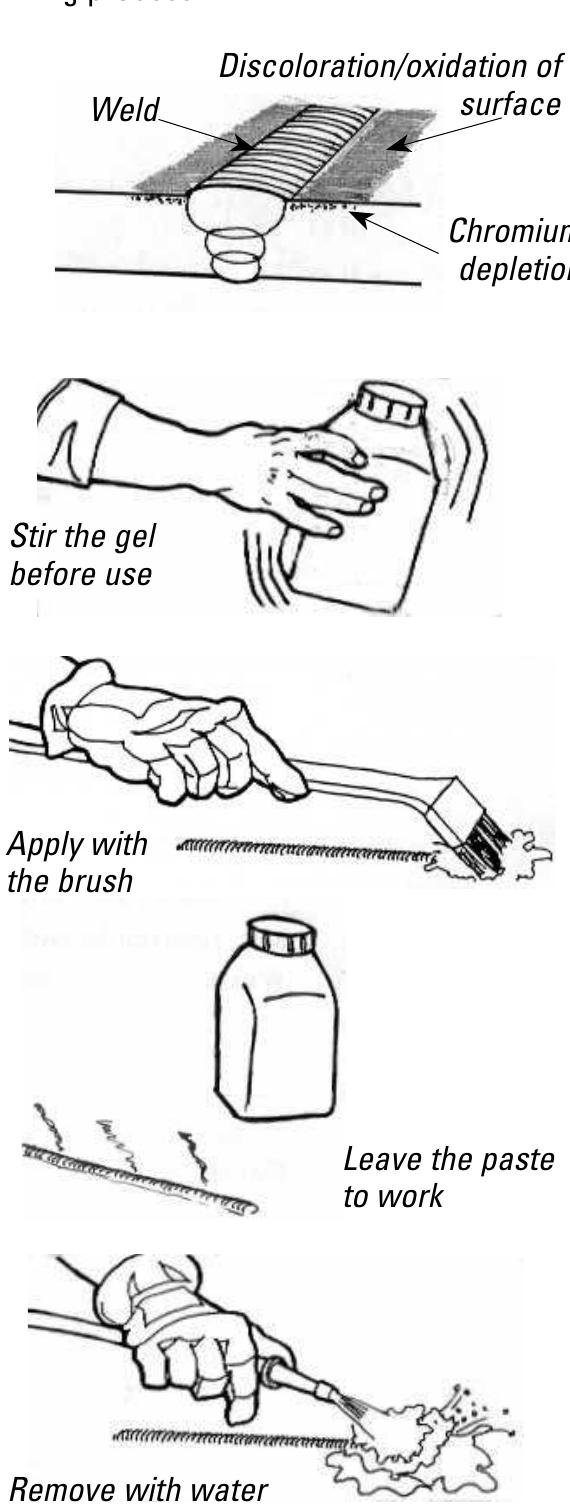

- DUPLEX-325 N Electrode for Duplex Steel . . . . . . . . . . . . . . . . . . . . PICKLING GEL Pickling Gel for Stainless Steel . . . . . . . . . . . . . . . . NIFE-334 N Nickel Iron Electrode for Cast Iron . . . . . . . . . . . . . NICKEL-333 N Nickel Electrode for Cast Iron . . . . . . . . . . . . . . . . .

- TINBRO-341 Electrode for Copper Alloys . . . . . . . . . . . . . . . . . . .

- ALBRONZE-344 Electrode for Copper Alloys . . . . . . . . . . . . . . . . . . . ALUMIN-351 N Electrode for Aluminum . . . . . . . . . . . . . . . . . . . . . . .

- CH-2-382 Electrode for Chamfering . . . . . . . . . . . . . . . . . . . . .

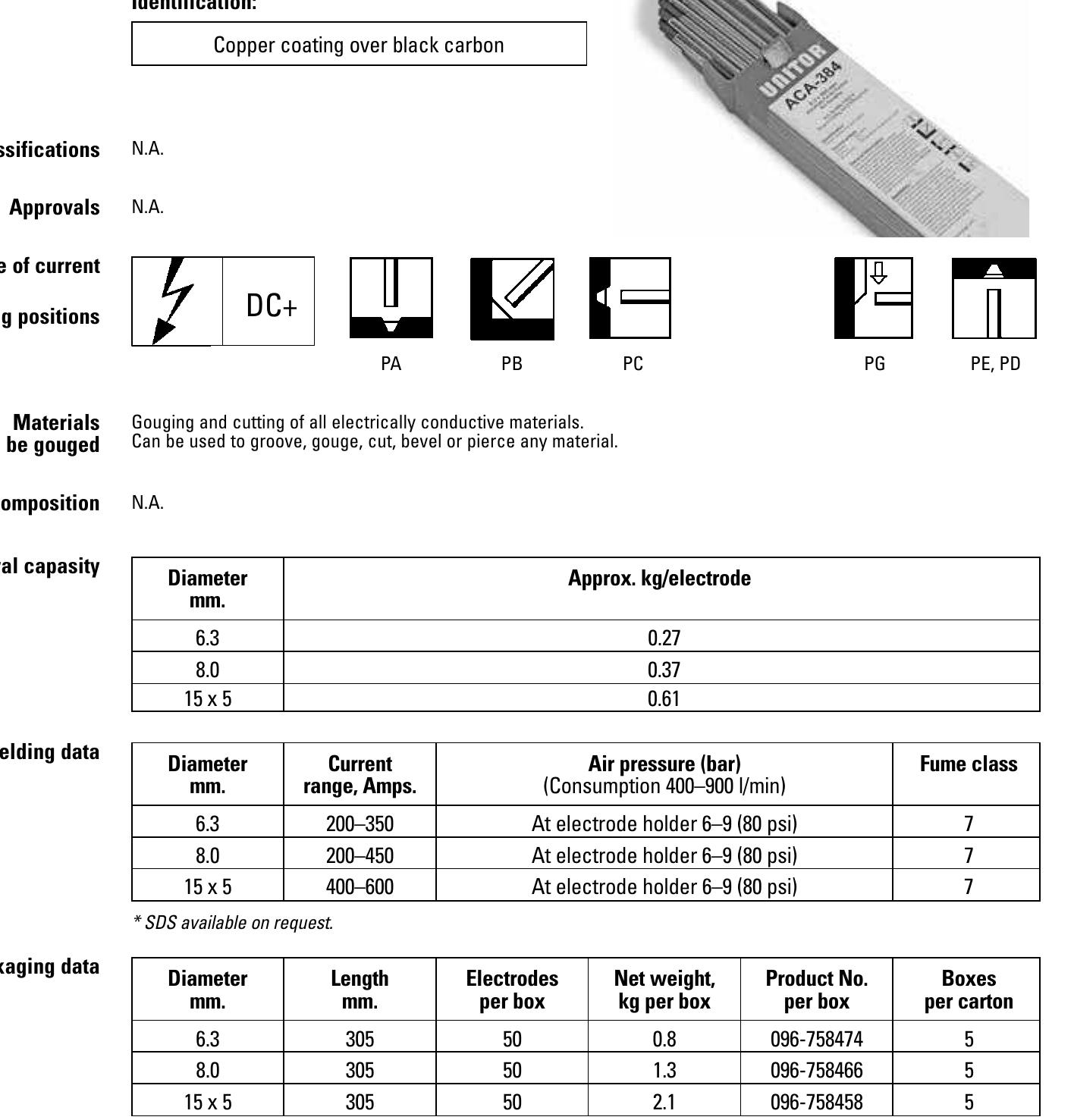

- ACA-384 Electrode for Air Carbon Arc Gouging . . . . . . . . . .

- Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- IMS-210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- ICROMO-216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Mo-221 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- IDUPLEX-222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- ALUMAG-235 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- ICUNI-30-239 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- IALBRO-237 MF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

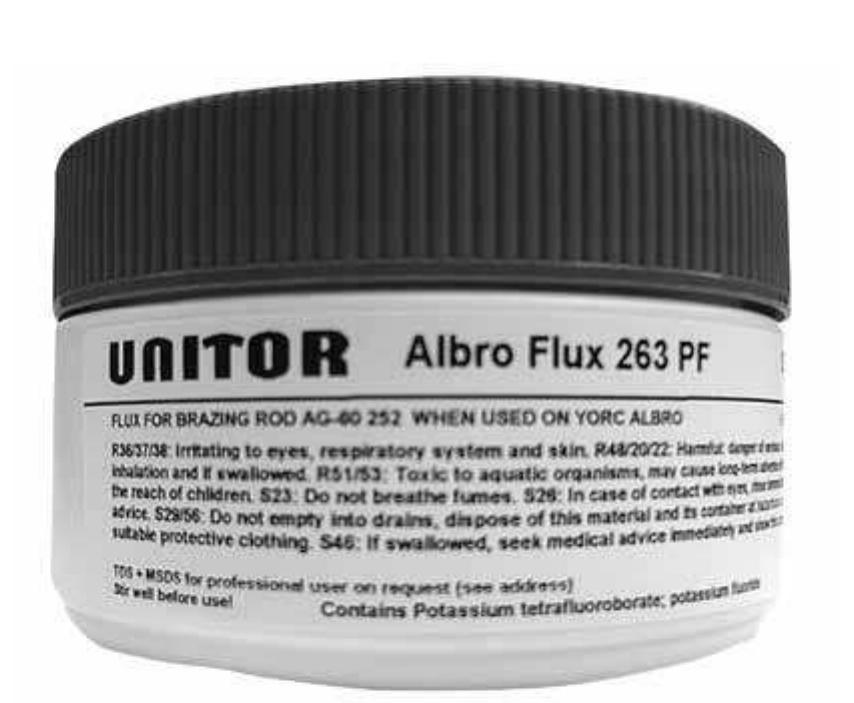

- I-FLUX-238 PF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

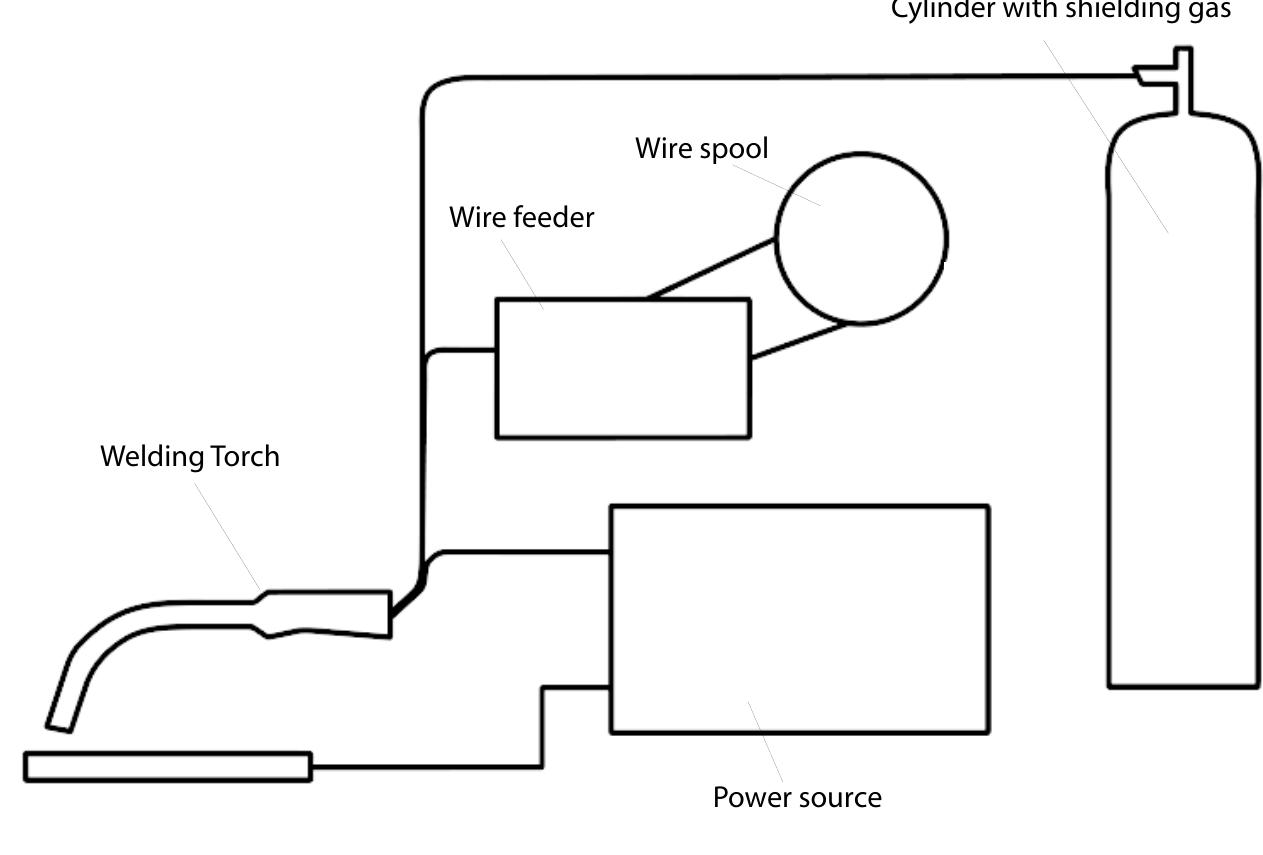

- Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Basic principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power source characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Selecting power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UWI-150 TP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UWI-230 TP AC/DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UWI-203 TP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UWR-320 TP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UWI-500 TP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Primary extension cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Secondary cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrode holders, cable connectors & return clamp assembly . . . .

- Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

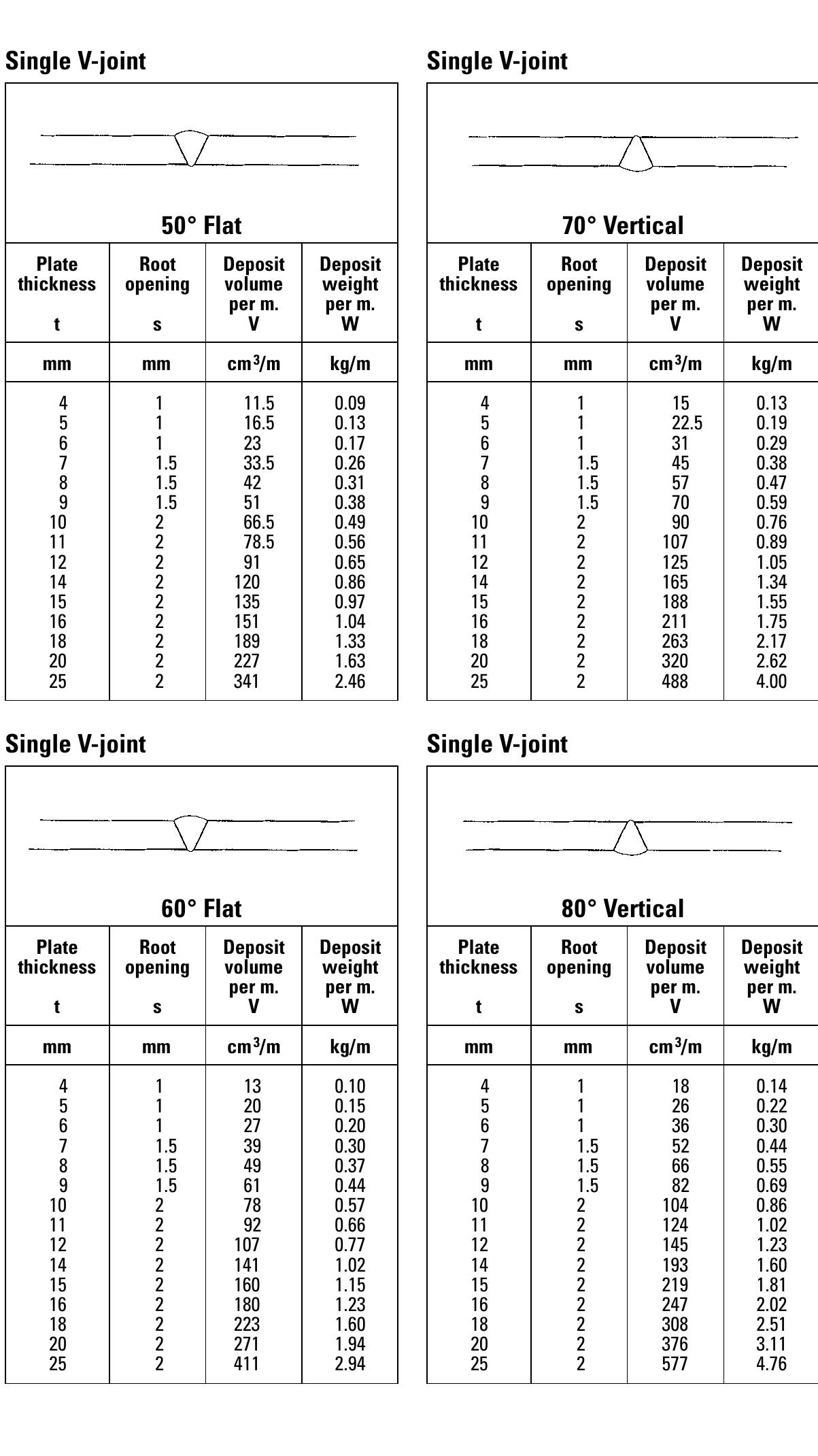

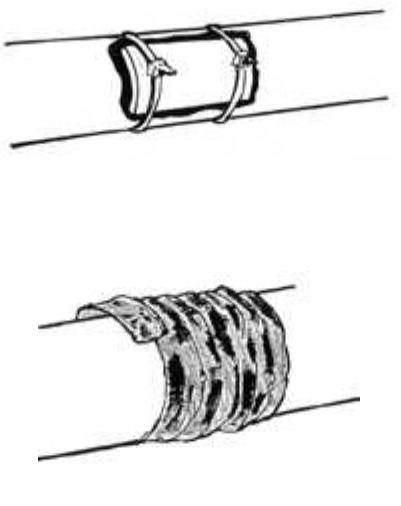

- Welding techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Edge preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrodes for electrode welding & gouging. . . . . . . . . . . . . . . . . . . . .

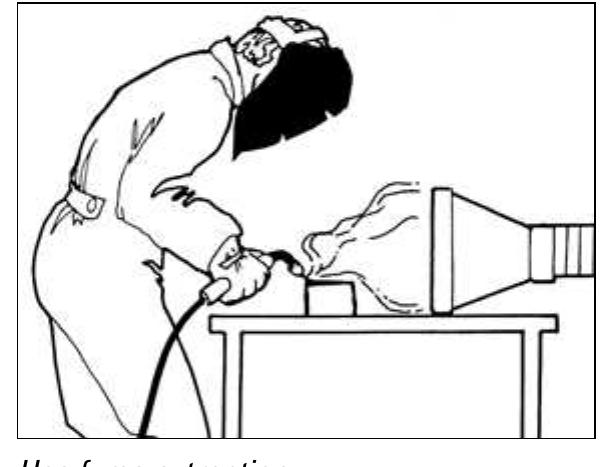

- Air Carbon arc gouging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Basic principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Plasma cutting equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UPC-310 TP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UPC-1041 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cutting technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maintenance and trouble shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- 04 Description Unit Product no. Inlet station Stainless steel 400 A 240x240x150 mm with Dix 70 male Pcs. 195-624320 Outlet station stainless steel 400 A 240x240x150 mm with Dix 70 female Pcs. 195-624338 Inlet station Stainless steel 800 A 300x300x200 mm with Dix 120 male Pcs. 195-736728 Outlet station stainless steel 800 A 300x300x200 mm with Dix 120 female Pcs. 195-736736 Remote control connection cable for UWI-320/400/500/UWR-852 Pcs. 195-608760 Remote control connection cable for UWR-303 Pcs. 195-603993 Remote control adapter for UWI-320/400/500/UWR-852 Pcs. 195-604157 Remote control adapter for UWR-303 Pcs. 195-604306 Cable connector Dix 70 male/female Pcs. 195-632893 Cable connector Dix 120 male/female Pcs. 195-736744 511089 Non return valve Ox.

- 520387 Non return valve Ac.

- 302505 High Pressure connector Ox.

- 517086 High Pressure connector Ac.

- 302547 Blind plug.

- 510021 Regulator 520 Ox pressure 0-16 bar.

- 585372 Flashback arrestor Ac 85-10.

- 9 621565 High Pressure connector AC.

- 9 621573 High Pressure connector OX. 10 624684 Bushing for steel pipes. 11 320226 Clamp No. 20 F/steel pipe. 12 550335 Cabinet F/outlet station, steel. 12 536805 Cabinet F/outlet station, glass fibre. 13 550319 Twin valve unit F/outlet.

- 14 510030 Regulator 530 Ac pressure 0-2.5 bar. 14 510031 Regulator 530 Ox pressure 0-16 bar. 15 708537 Flasback arrestor S55 Ac. 15 708545 Flashback arrestor S55 Ox. 16 235010 Stretch relief bracket. Signs for entrance doors 526533 «Acetylene» (100x500) 526541 «Oxygen» (100x500) 183202 «Gas under pressure» (250x450) 526566 «Gas danger» small (150x300) 516625 «Gas danger» large (300x600) 526558 «No admittance» (200x500) Instructions signs for gas central 176404 «Acetyleng instruction» (350x300) 176412 «Oxygen instruction» (350x300) 183236 «Piperline pressure» (190x145) Signs for outlet station 183244 «Close valves (90x75) 511253 «Working pressures» (70x200) NOTE: The «Gas danger» small sign shall be placed at the outlet point of the ventilation pipes from the central regulators. (Size in mm HxW)

Julián Méndez Torres

Julián Méndez Torres