The Welding Handbook for maritime welders The Welding Handbook

Abstract

Notice: All welding is carried out on the welder's own risk and account. Welding should be executed by a qualified and experienced welder and adequate safety measures should always be adhered to. The information and guidelines in this Welding Handbook are based on general information and knowledge at hand and are believed to be accurate and reliable, but the information and guidelines are not to be taken as a guarantee or warranty for a special purpose. The information and guidelines are provided to the welder solely for his own consideration, and Wilhelmsen Maritime Services AS assumes no legal responsibility or liability for eventual damages and/or losses should the information and/or guidelines turn out to be incorrect or un-suitable. Wilhelmsen Maritime Services AS is not liable for any loss or damages whatsoever and howsoever arising which is due to force majeure, other events beyond the reasonable control of Wilhelmsen Maritime Services AS or events that could not reasonably be foreseen by Wilhelmsen Maritime Services AS when this Welding Handbook was made. Wilhelmsen Maritime Services AS is in no event liable for indirect, incidental or consequential damages or losses, including damages for loss of profits, resulting from lack of conformity, including but not limited to loss resulting from goods or software not working when connected to other goods/software or for any related cause thereto. Wilhelmsen Maritime Services AS's liability shall in any event not exceed the total purchase price of the Wilhelmsen Maritime Services AS goods used during the welding operations. Theses conditions are automatically accepted by anybody using the information and guidelines in this Welding Handbook.

References (104)

- Coated Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 TIG Welding Rods & Fluxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

- Wires for Wire Welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

- Gas Welding Rods & Fluxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

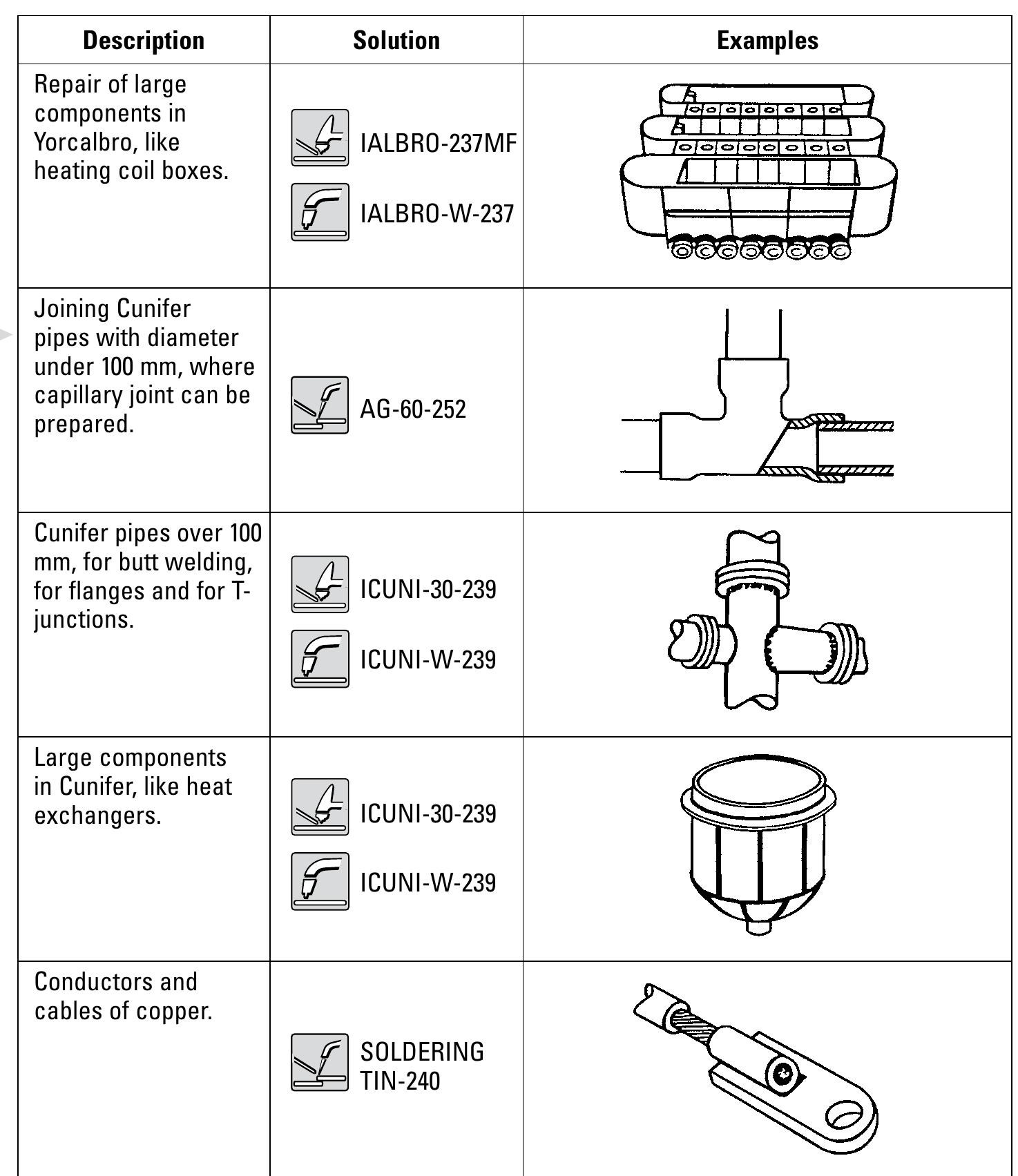

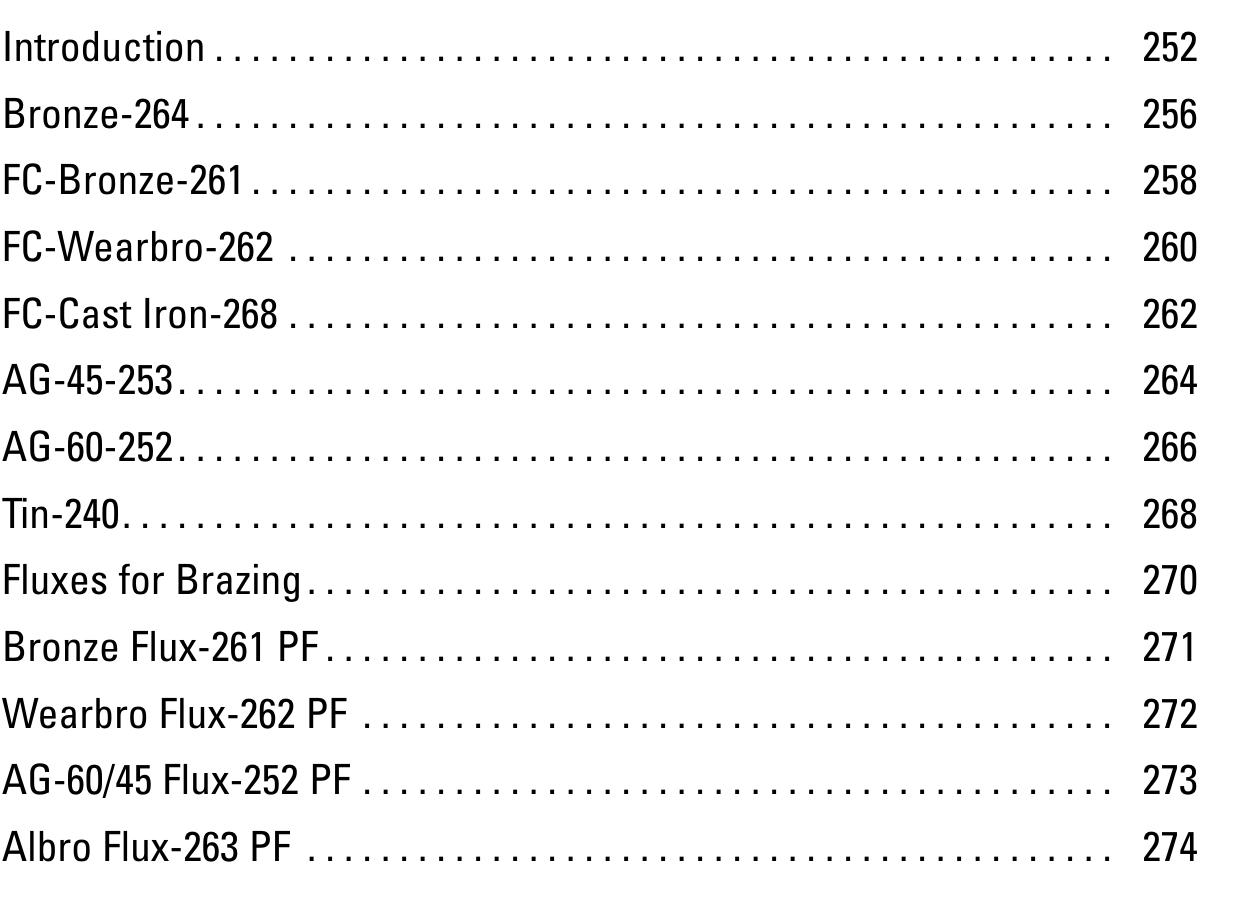

- Brazing Rods & Fluxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

- Cold Repair Compounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 3.01 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 Types of electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Storing and re-drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134 Classification and approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

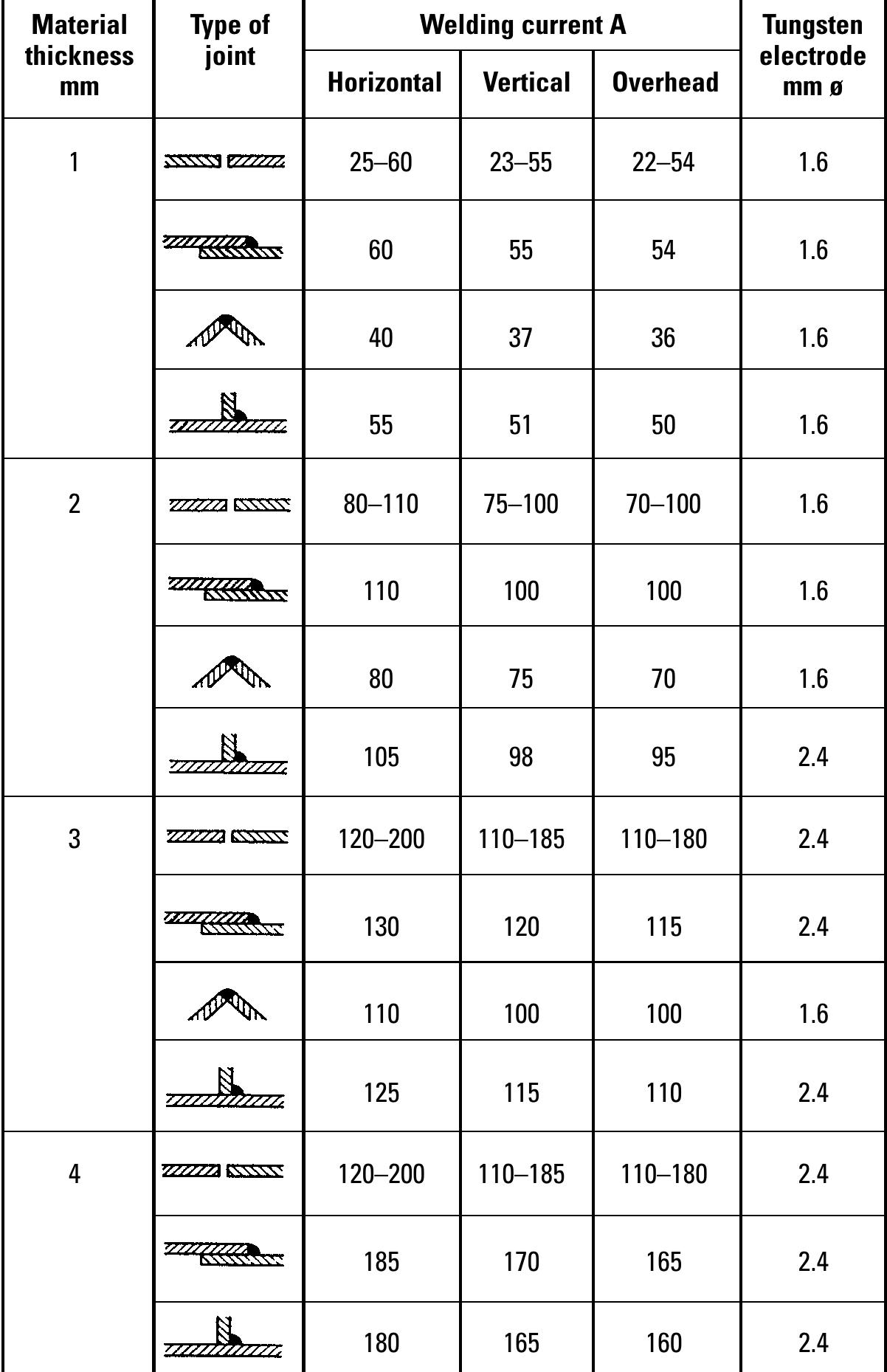

- Welding positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

- GPO-30 N General Purpose Electrode For Mild Steel . . . . . . 150

- GPR-300H High Recovery Electrode for Mild Steel . . . . . . . . . 15 SPECIAL-303 N Double Coated Electrode for Mild and Ship Quality Steel . . . . . . . . . . . . . . . . . . . . . . . . 154

- LHH-314 High Recovery Low Hydrogen Electrode for Ship Quality Steel . . . . . . . . . . . . . . . . . . . . . . . . . 158

- LHV-316 N Vertical Down Welding Low Hydrogen Electrode for Ship Quality Steel . . . . . . . . . . . . . . . . 160

- LHT-318 N Electrode for High Temperature Steel . . . . . . . . . . 16

- LHL-319 N Electrode for Low Temperature Steel . . . . . . . . . . . 164

- LHR-30 N Electrode for Weathering Steel . . . . . . . . . . . . . . . . 166

- TENSILE-38 N Electrode for Difficult-to-Weld Steel. . . . . . . . . . . . 168 IMPACT-39 S Electrode for Heat Resistant Overlays . . . . . . . . . . 170

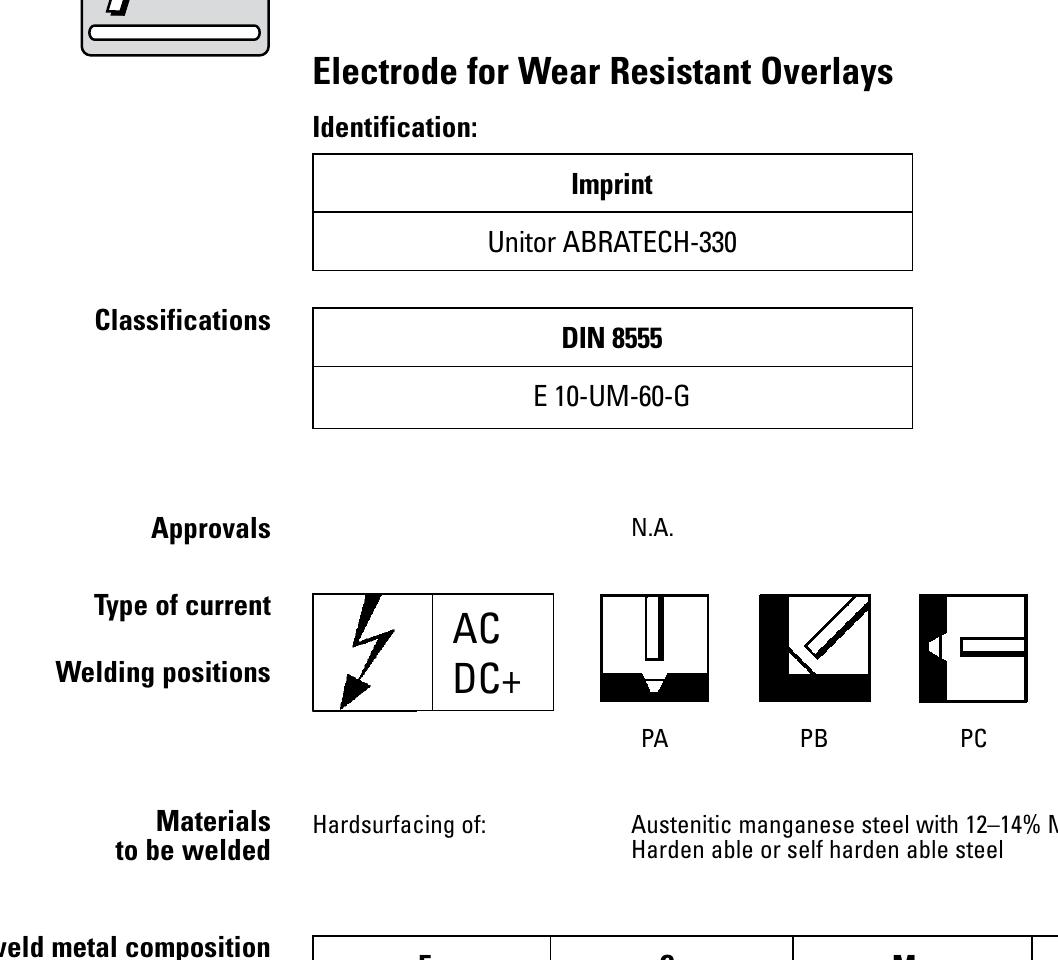

- WEARMAx-37 Electrode for Joining & Wear Resistant Overlays 17 ABRATECH-330 Electrode for abrasive wear . . . . . . . . . . . . . . . . . . . 174 18/8-31 N Electrode for Stainless Steel . . . . . . . . . . . . . . . . . . 176

- 3/14-3 N Electrode for Stainless Steel . . . . . . . . . . . . . . . . . . 178

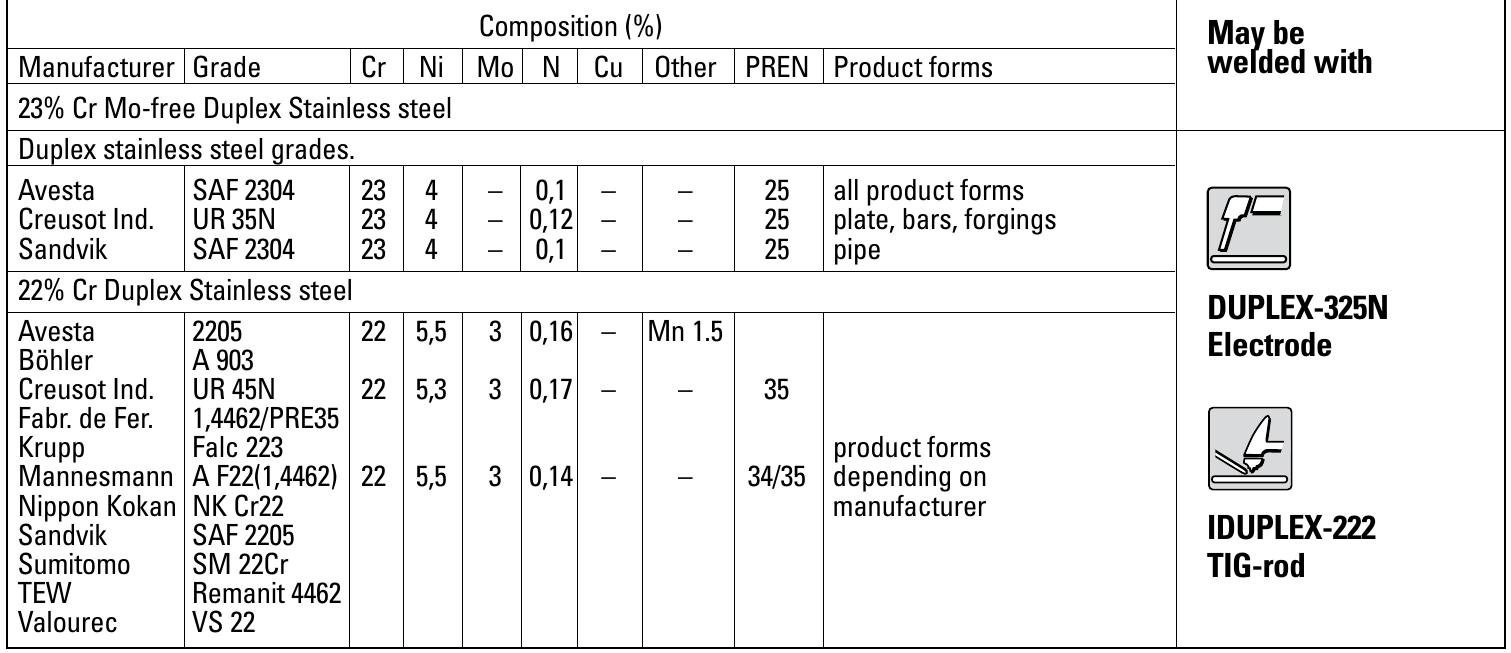

- DUPLEx-35 N Electrode for Duplex Steel . . . . . . . . . . . . . . . . . . . . 180 PICKLING GEL Pickling Gel for Stainless Steel . . . . . . . . . . . . . . . . 18

- NIFE-334 N Nickel Iron Electrode for Cast Iron . . . . . . . . . . . . . 184

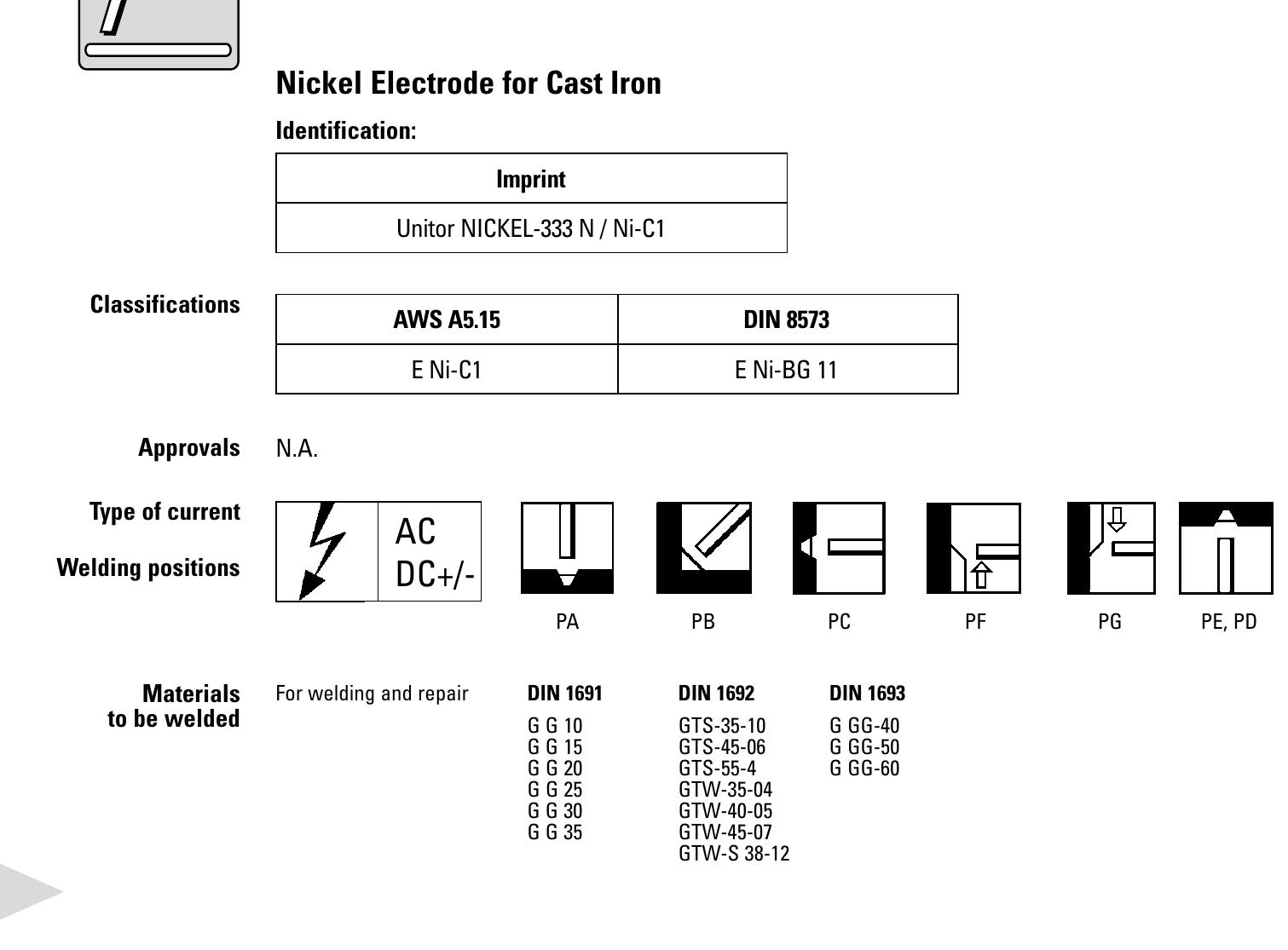

- NICKEL-333 N Nickel Electrode for Cast Iron . . . . . . . . . . . . . . . . . 186

- TINBRO-341 Electrode for Copper Alloys . . . . . . . . . . . . . . . . . . . 188

- ALBRONZE-344 Electrode for Copper Alloys . . . . . . . . . . . . . . . . . . . 190 ALUMIN-351 N Electrode for Aluminum . . . . . . . . . . . . . . . . . . . . . . . 19

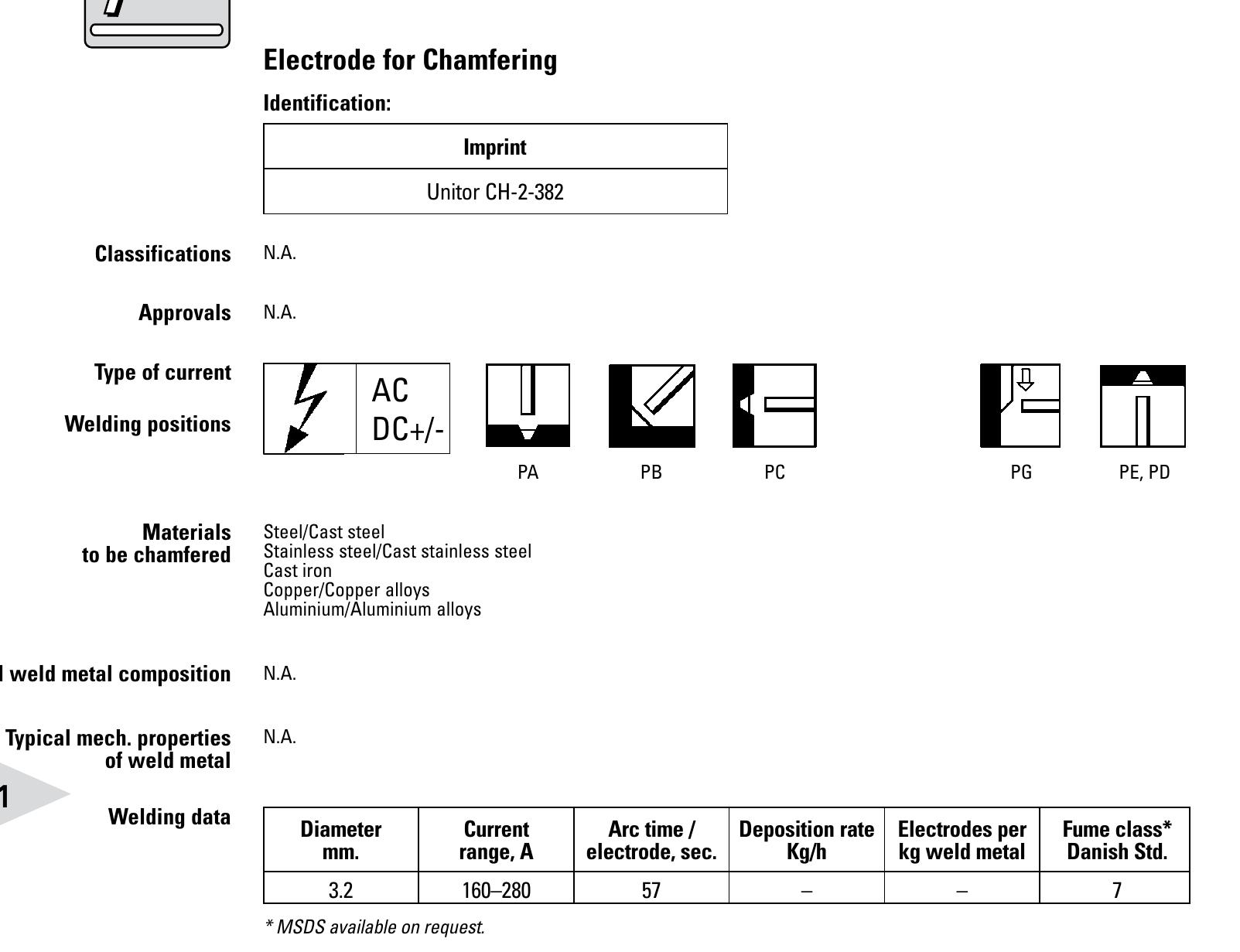

- CH--38 Electrode for Chamfering . . . . . . . . . . . . . . . . . . . . . 194

- ACA-384 Electrode for Air Carbon Arc Gouging . . . . . . . . . . 196

- Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00

- Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01 IMS-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- ICROMO-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04 18/8

- Mo-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06

- IDUPLEx-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 08

- ICUNI-30-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

- IALBRO-37 MF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- I-FLUx-38 PF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

- Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

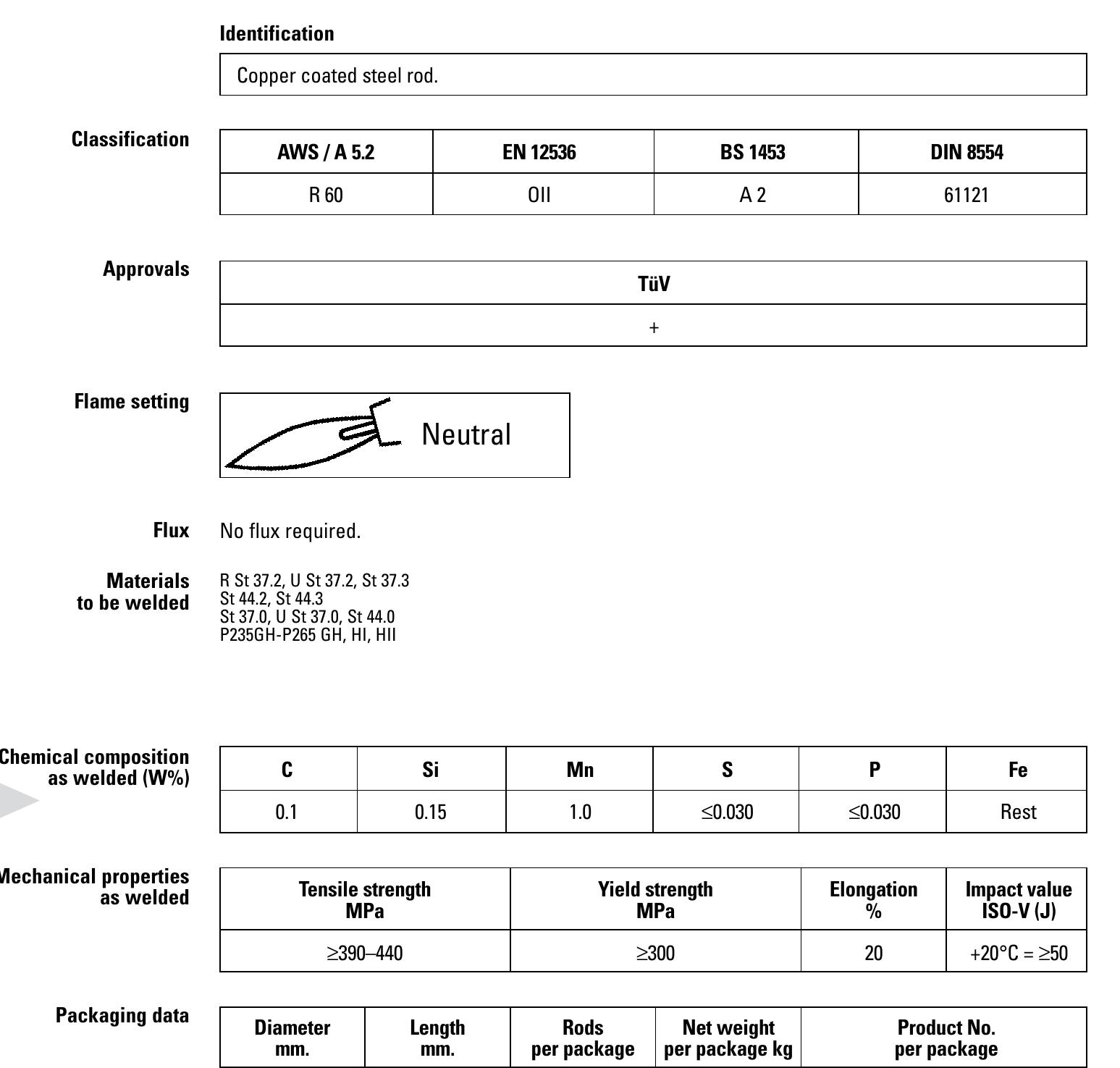

- MS-00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

- Alumag-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

- Aluflux-34 F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

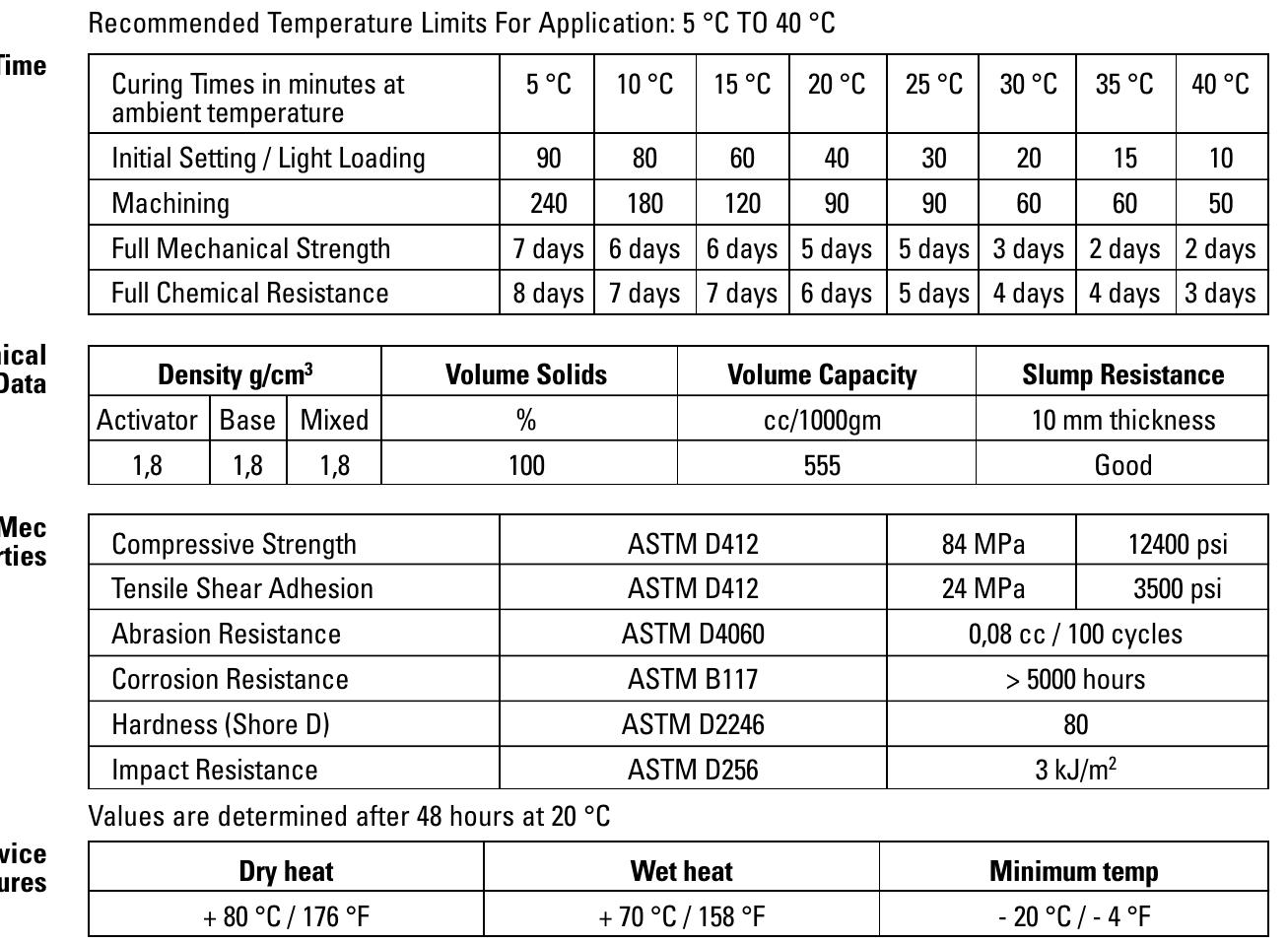

- Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78 Typical application areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78 How do Cold Repairs work? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 How to prepare the surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 How to apply the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

- Polymer Cold Repair Kit-A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

- Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

- Leak Stop -Pipe repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

- Metalgrade Ready-Stick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Metalgrade Express . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

- Metalgrade Rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

- Metalgrade Hi-Temp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

- Aquagrade Rebuild. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

- Ceramigrade Rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

- Ceramigrade Liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

- Ceramigrade Abrashield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

- Rubbergrade 6 Rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

- Rubbergrade 6 Remould . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

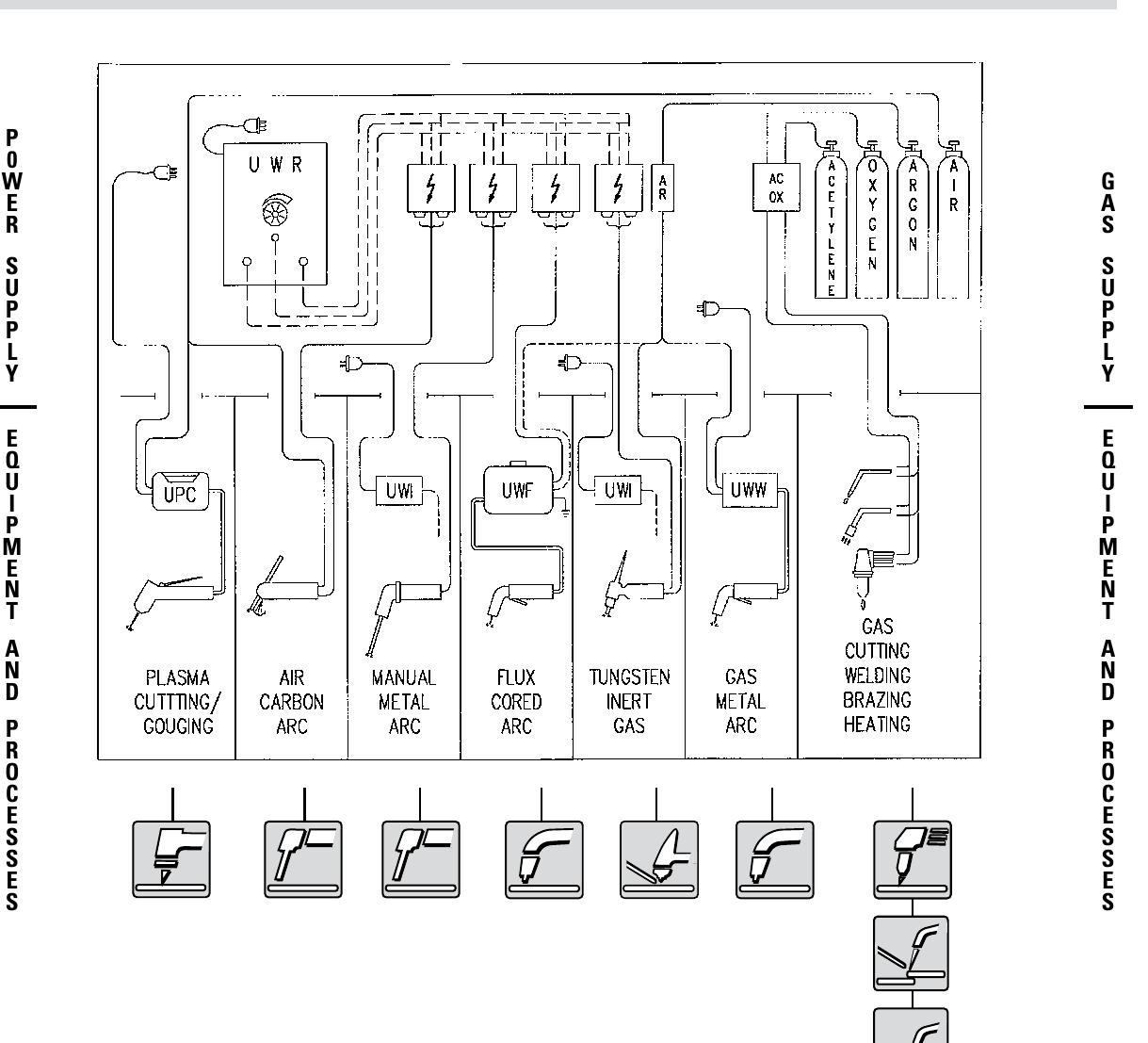

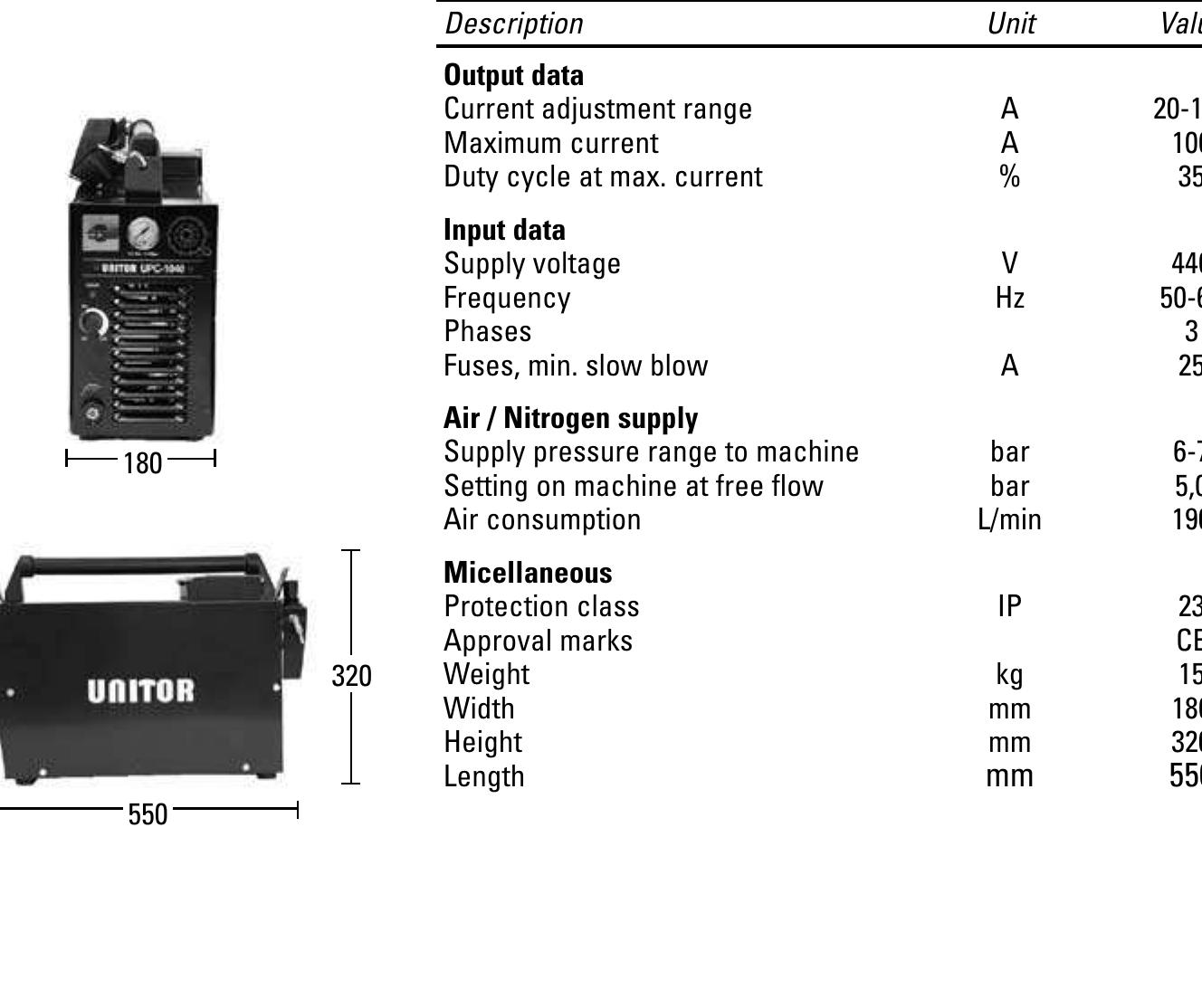

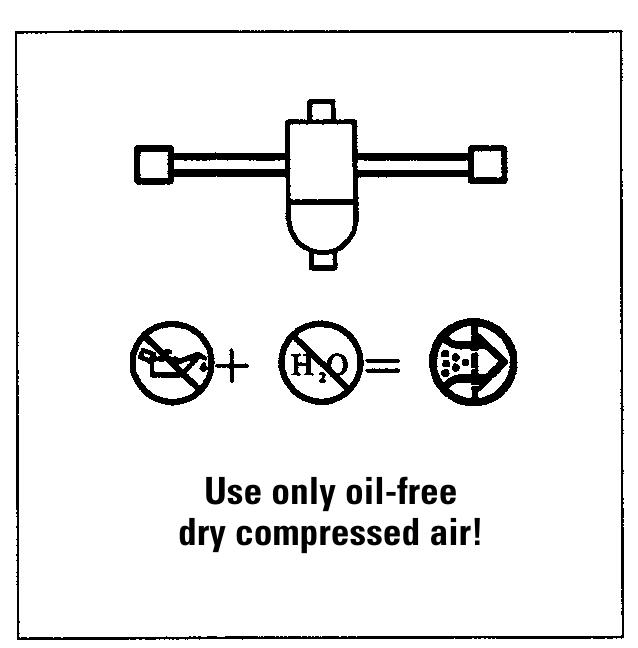

- Electric Welding Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335 Electrode welding & gouging. . . . . . . . . . . . . . . . . . . . . . . . . 335 TIG welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

- Wire welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403 Plasma cutting & gouging. . . . . . . . . . . . . . . . . . . . . . . . . . . . 441 Current distribution system . . . . . . . . . . . . . . . . . . . . . . . . . . 455

- 4.01 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Basic principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power source characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Selecting power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

- UWI-150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UWI-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- UWR-303. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

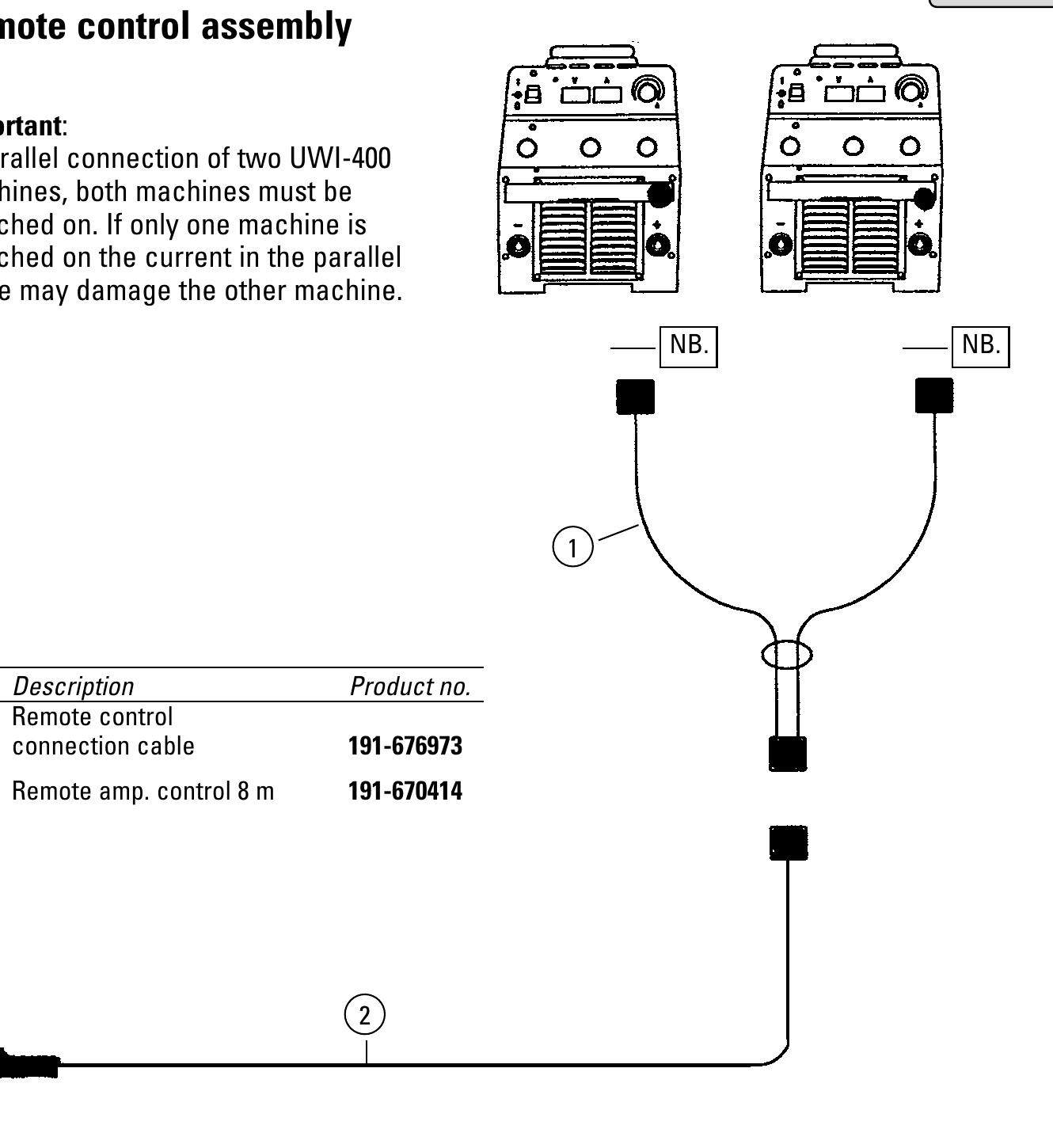

- UWI-400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

- UWR-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Primary extension cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Secondary cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrode holders, cable connectors & ground clamp assembly . . .

- Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

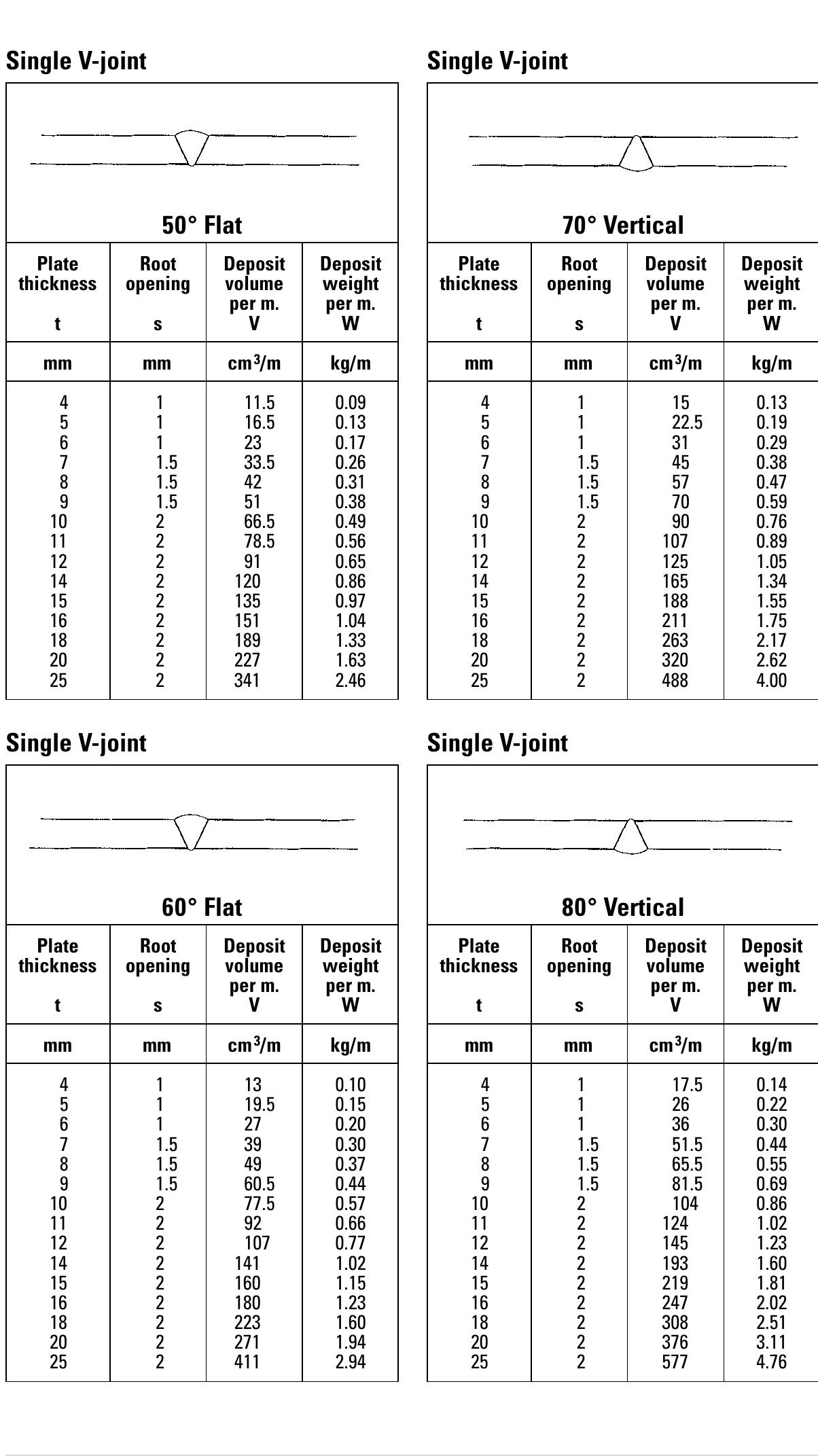

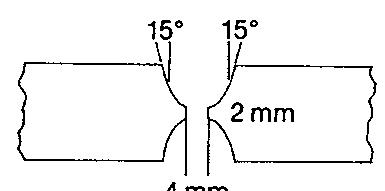

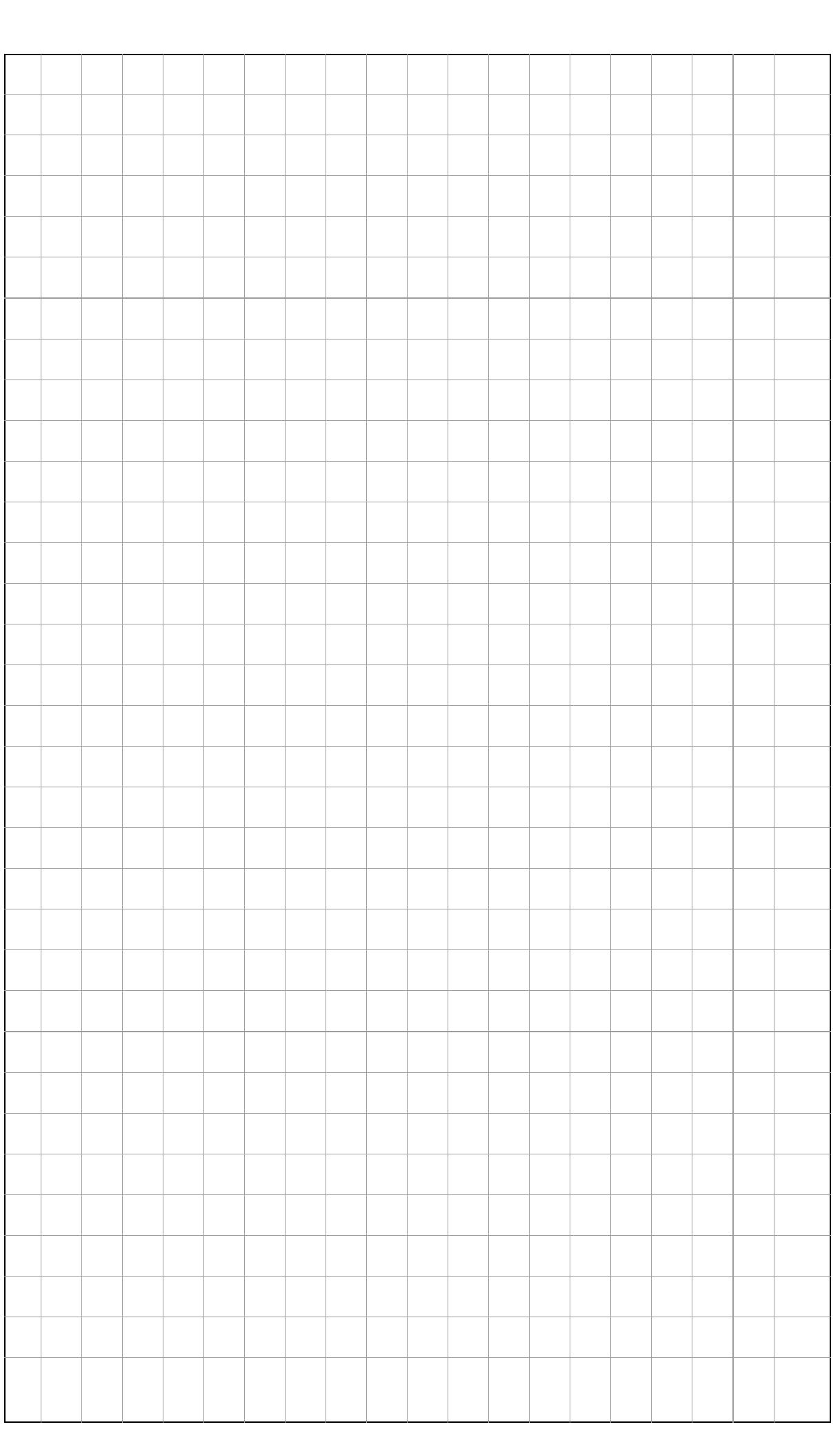

- Welding techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Edge preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrodes for electrode welding & gouging. . . . . . . . . . . . . . . . . . . . . Air Carbon arc gouging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . UWI-134 DP 197-60781 N.A. UWI-140 197-60781 N.A. UWI-150 197-60781 N.A. 197-607810 197-510010 176-576157 176-175596 176-175505 196-63794 197-597310 197-59738

- UWI-400 197-67693 191-670414 (191-67694) Remote amp control 8 m fits on to TIG torch by Velcro straps. Must be added if TIG torch is to function in TIG mode on UWI-400.

- 02 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

- Basic principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

- Shielding gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

- Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

- Speedweld-160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414 SC 1 RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

- Regulator & accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

- Application areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Preparation for welding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

- Welding technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

- Edge preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

- Wires for wire welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

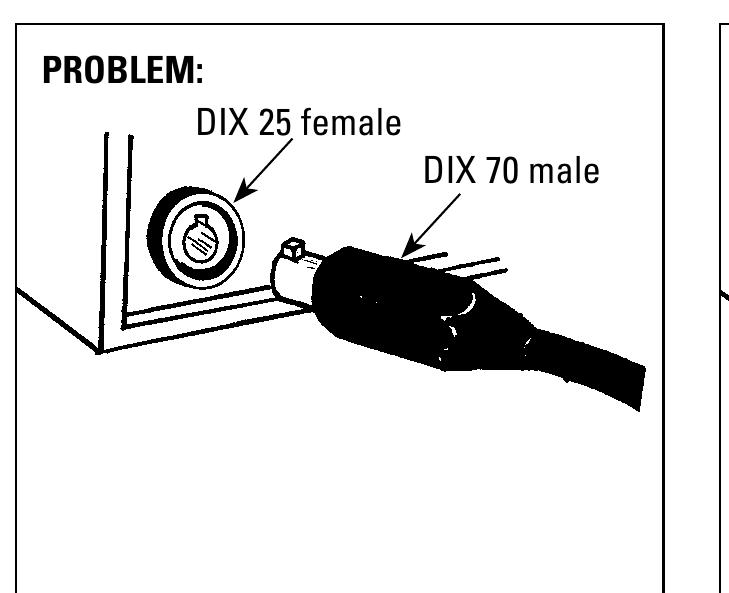

- Description Unit Product no. Inlet station Stainless steel 400 A Pcs. 195-624320 Outlet station stainless steel 400 A Pcs. 195-624338 Inlet station Stainless steel 800 A Pcs. 195-736728 Outlet station stainless steel 800 A Pcs. 195-736736 Remote control connection cable cable for UWI-350 MP Pcs. 195-624577 Remote control connection cable cable for UWI-400/UWR-85 Pcs. 195-608760 Remote control connection cable cable for UWR-303 Pcs. 195-603993 Remote control adapter for UWI-400/UWR-85 Pcs. 195-604157 Remote control adapter for UWI-303 Pcs. 195-604306 Cable connector Dix 70 male/female Pcs. 195-632893 Cable connector Dix 10 male/female Pcs. 195-736744 PROCESS & EqUIPMENT Gas Welding Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

- Ac/Ox cutting, welding, brazing. . . . . . . . . . . . . . . . . . . . . . . 461 Gas supplies and gas distribution system . . . . . . . . . . . . . . 511

- 5.01 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

- The Combination Torch UCT-500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

- UCT-500 Components and spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

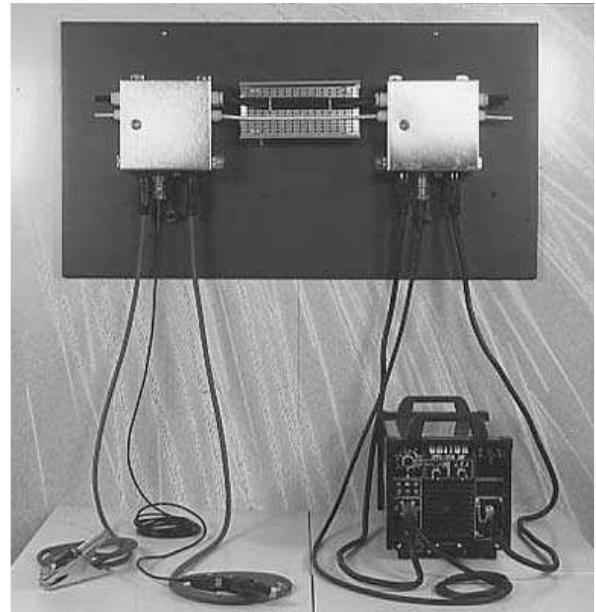

- The Unitor Workshop Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

- Welding and grinding goggles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 470

- Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

- Portable gas equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

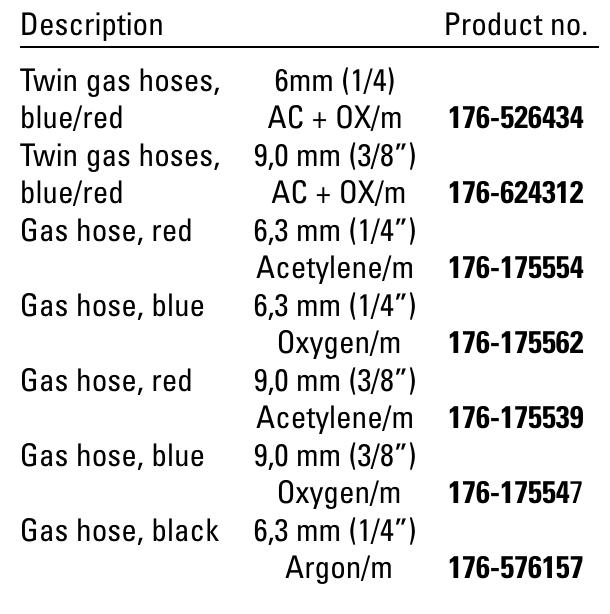

- Gas hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

- Hose connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

- Gas regulators for cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

- Flashback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

- Flashback arrestors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

- The acetylene/oxygen flame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 484

- Operating instructions for UCT-500 cutting torch . . . . . . . . . . . . . . . . . 486

- Cutting procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488

- Common cutting faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

- Operating instructions for UCT-500 brazing, welding & heating torch 49 Maintenance of blowpipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 494

- Heating techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 496

- Flame straightening techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

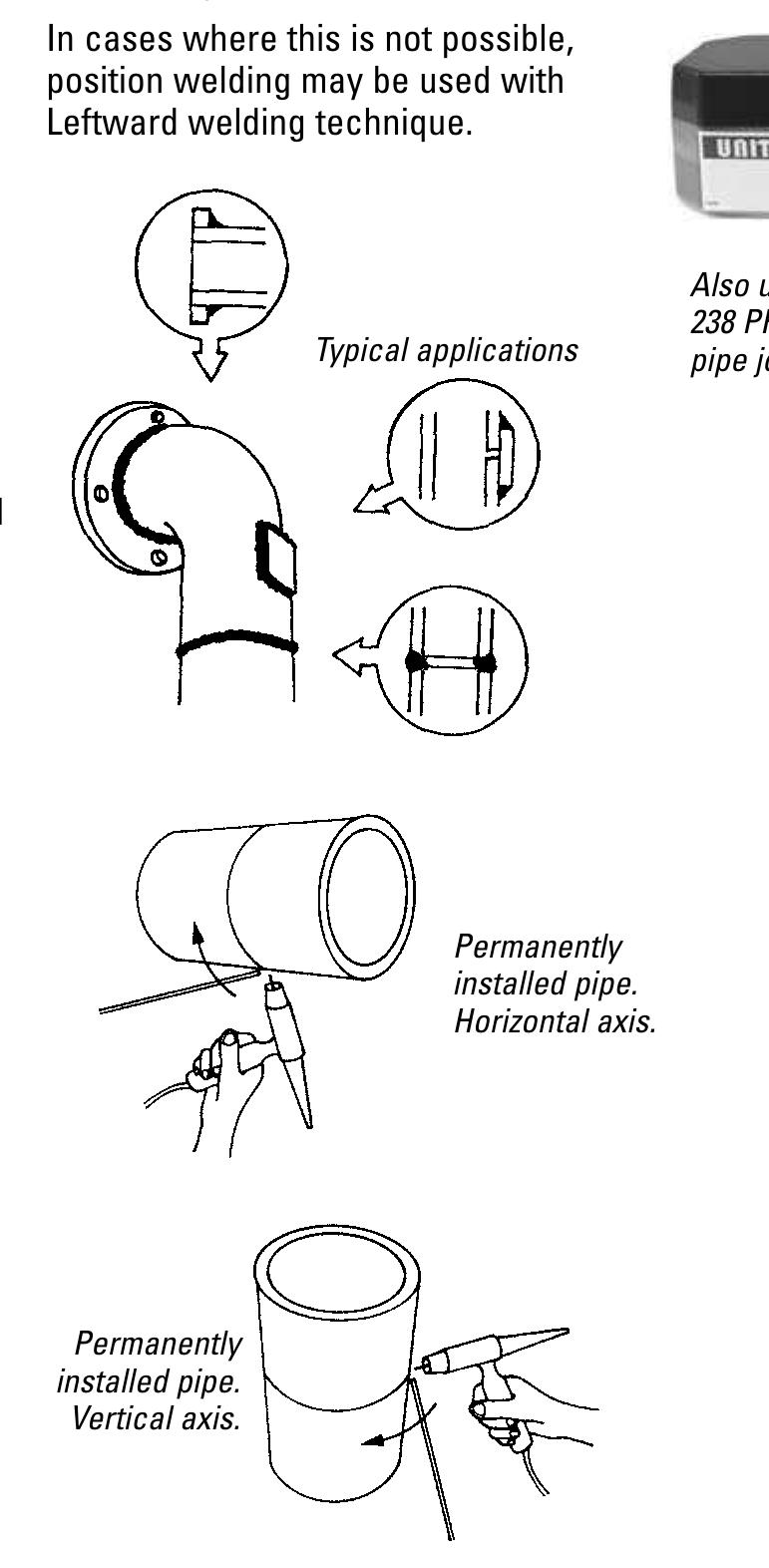

- Welding techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 499

- Butt joints for gas welding of steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

- Consumables and parameters for gas welding . . . . . . . . . . . . . . . . . . 503

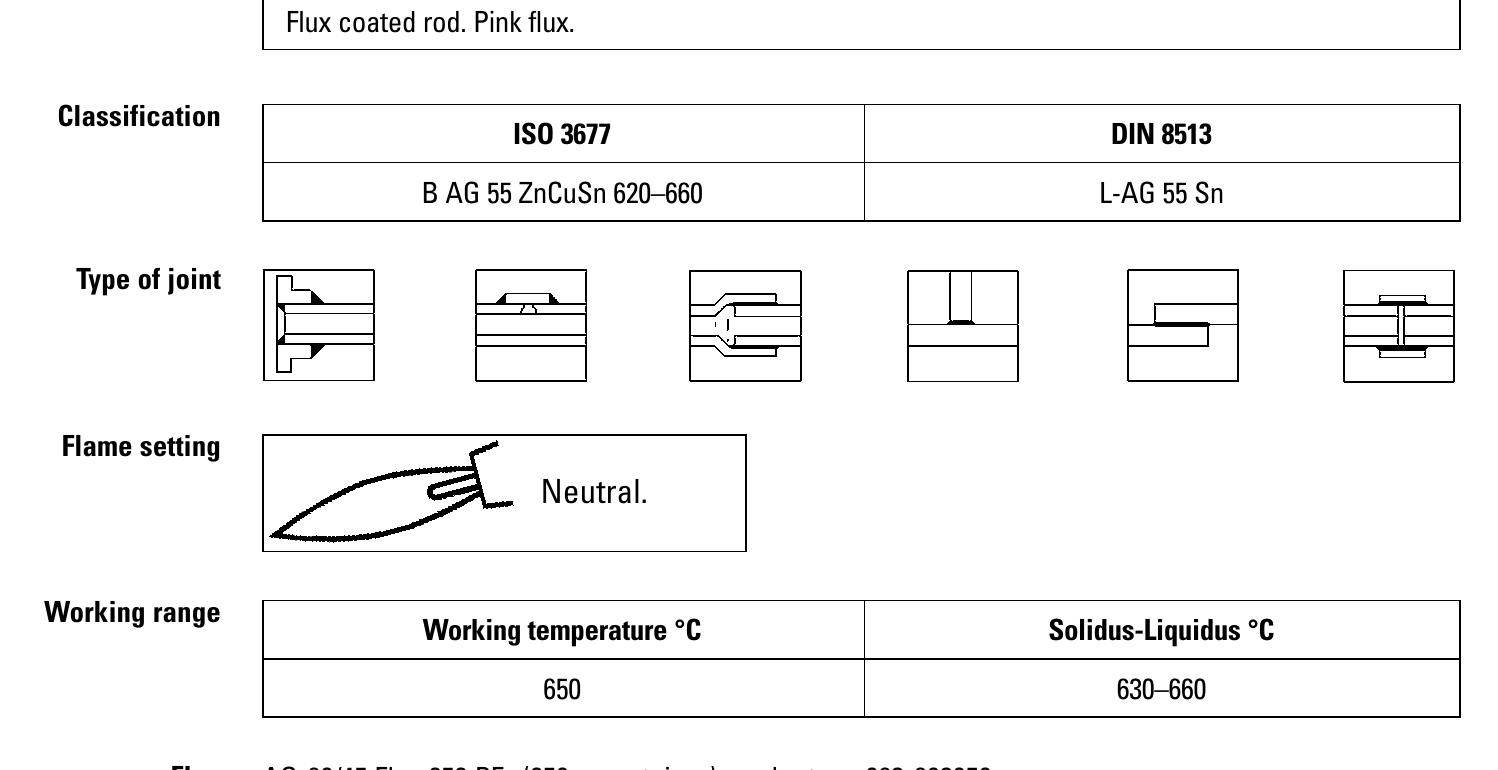

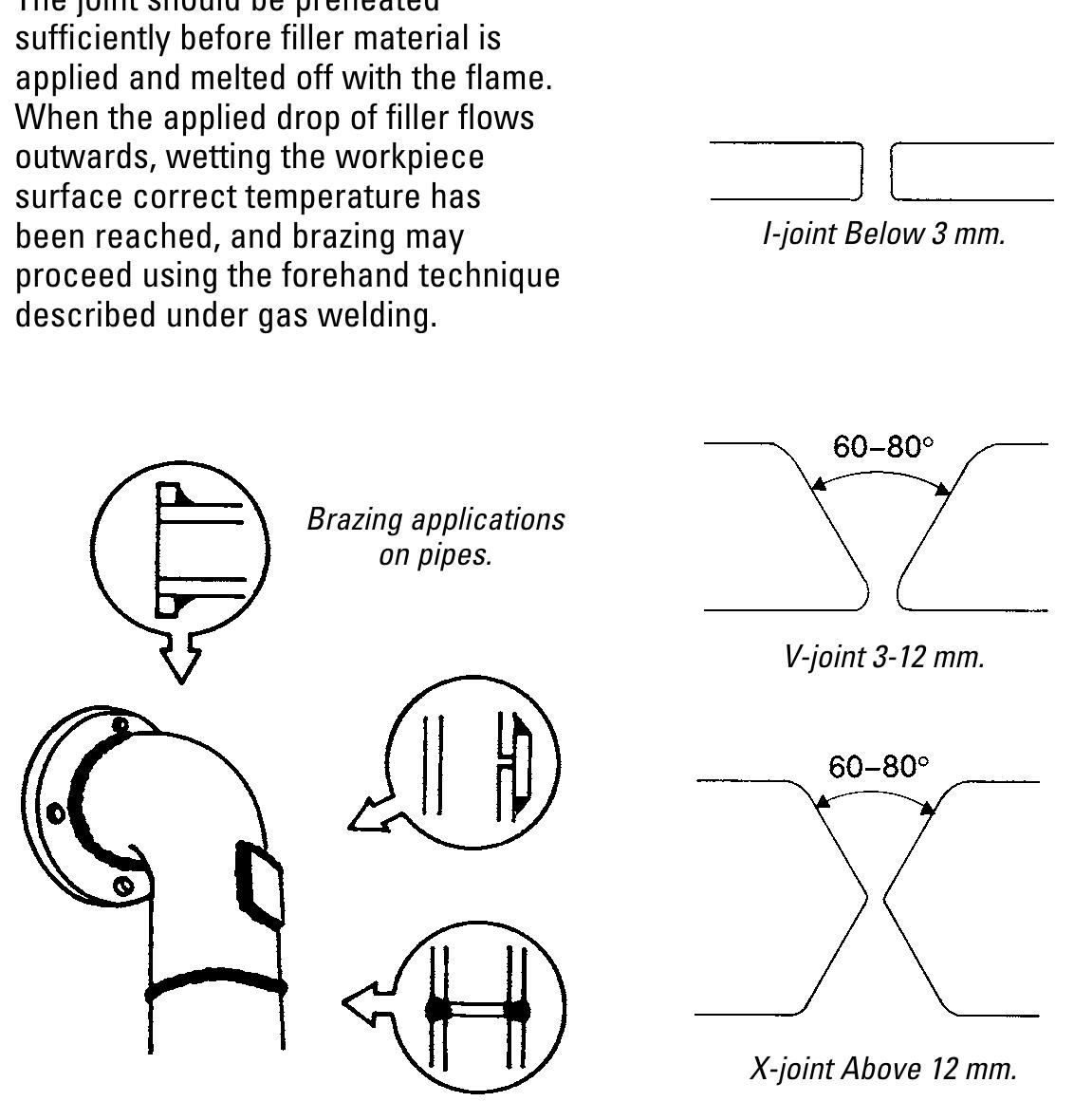

- Soldering and brazing techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 504

- Edge preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

- Consumables and parameters for brazing . . . . . . . . . . . . . . . . . . . . . . . 508 UCT-500 Master kit in heavy duty PVC case, Product number: 170-500000

- UCT-500 Compact kit in heavy duty PVC case, Product number: 170-500001

- 01 T-bars, straightening in web direction Heat both flanges, first no. 1 starting at the arrow head, and then no. .

- T-bars, straightening the web sideways Heat both flanges, first no.1 starting at the arrow head, and then no. .

- 01 International system of units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- The Greek Alphabet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . General conversion factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

- Roman numerals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Metric and decimal equivalents of fractions of an inch . . . . . . . . . . . Wire cross section AWG/mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Common gauge series for sheet thickness and wire. . . . . . . . . . . . . . Physical properties of some elements . . . . . . . . . . . . . . . . . . . . . . . . . . Hardness comparison table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Corrosion of galvanic couples in sea water . . . . . . . . . . . . . . . . . . . . . Temperature scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressure variations related to temperature. . . . . . . . . . . . . . . . . . . . . . Abbreviations and welding terminology. . . . . . . . . . . . . . . . . . . . . . . . . 54 6.00 Barwil Unitor Ships Service Mail: P.O. Box 33 NO-1324 Lysaker, Offi ce: Strandveien 20, 1326 Lysaker, Norway Tel: +47 67 58 45 50, Fax: +47 67 58 45 70, Internet: www.barwilunitor.com Price: USD 25.00

- Id no. 811002 Rev: 03, Printer: Pozkal/ Brdr. Fossum, 10 k. 08.07. Country of origin NO. All reasonable care has been taken in compiling the information in this document. All recommendations and sugges- tions on the use of Unitor products are made without guarantee since the conditions of use are beyond the control of the Company. It is the customer's responsibility to ensure that each product is fit for its intended purpose and that the actual conditions of use are suitable. This book and any advice is provided by Barwil Unitor accordingly on terms that no liability (including liability for negligence) will attach to the Company or its servants or agents arising out of or in connection with or in relation to this brochure or any such advice. Any goods supplied by the Company will be supplied solely upon its standard conditions of sale, copies of which are available on request. The Company's policy of continuous product development renders specifica- tions liable to modification. Information provided in this book is therefore subject to change without prior notification.

helton bruze

helton bruze