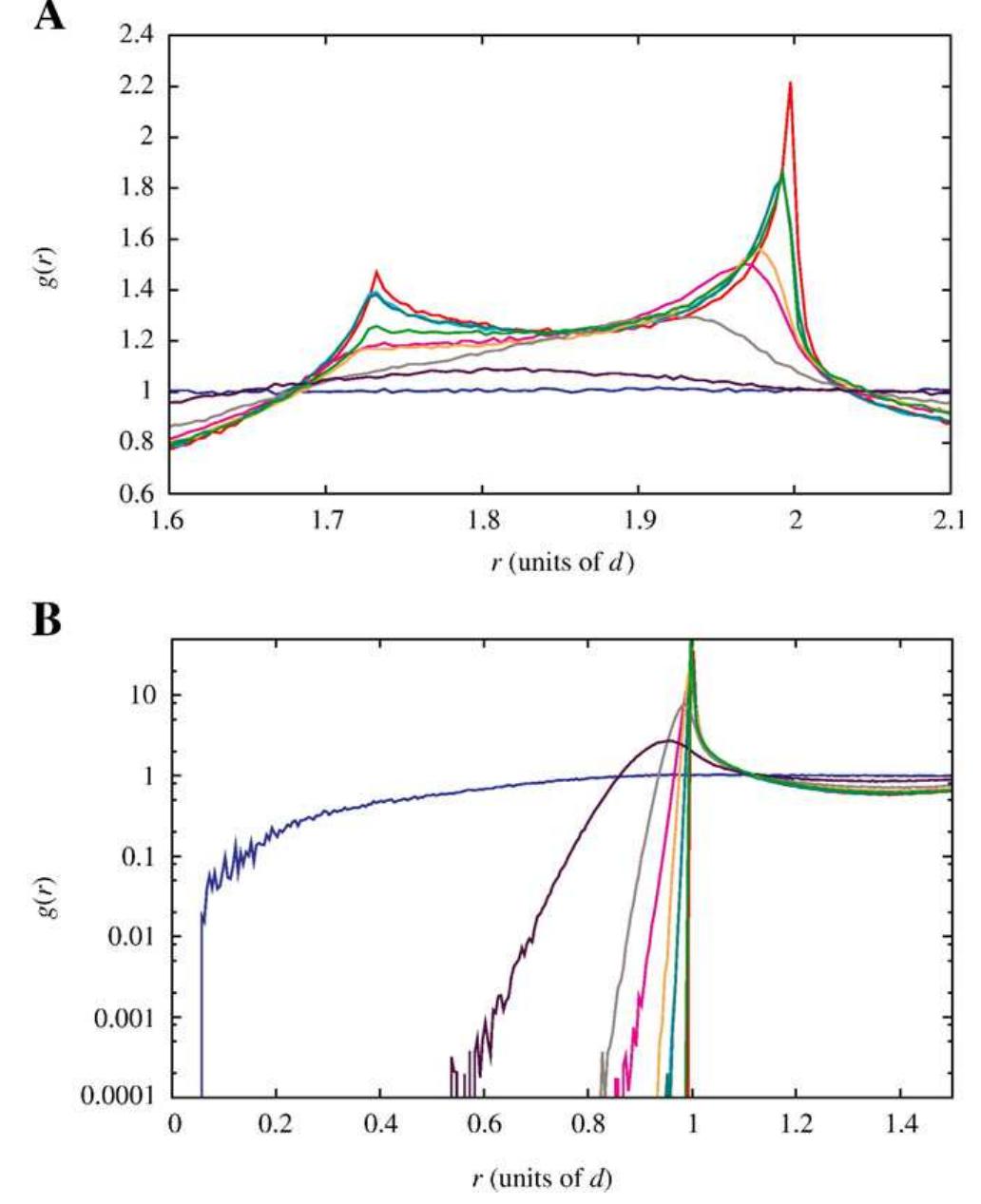

We develop a multiscale simulation method for dense granular drainage, based on the recently proposed spot model, where the particle packing flows by local collective displacements in response to diffusing "spots" of interstitial free... more

The motility of a population of swimming bacteria can be characterized by a random motility coefficient, p, the operational equivalent of a diffusion coefficient at the macroscopic level and in the absence of interacting chemical... more

Nine non-noble-metal catalysts (NNMCs) from five different laboratories were investigated for the catalysis of O 2 electroreduction in an acidic medium. The catalyst precursors were synthesized by wet impregnation, planetary ball milling,... more

The nitrogen-doped diamond films have been successfully synthesized by using urea as the nitrogen source. Selected-area deposition of diamond nuclei was formed by using a SiO 2 layer as the masking material. Diamond pads, around 9 mm in... more

A versatile method for positive-type patterning of polyimide (PI) based on a two-layer photosensitive poly(benzoxazole) (PSPBO) and poly(amic acid) (PAA) film has been developed to provide a promising material in the field of... more

Today, renewable energy sourcese.g. forest biomassare of great importance, not only domestic but also industrialf.i. wood fired power stationutilization is wide spread as well. However, the comminution of such fibrous texture materials... more

The general purpose of this work is to examine the relative ability of some well-selected zeolitic materials for the reduction of HC emissions generated within the Diesel "cold-start" period, i.e. when the work temperature of the Diesel... more

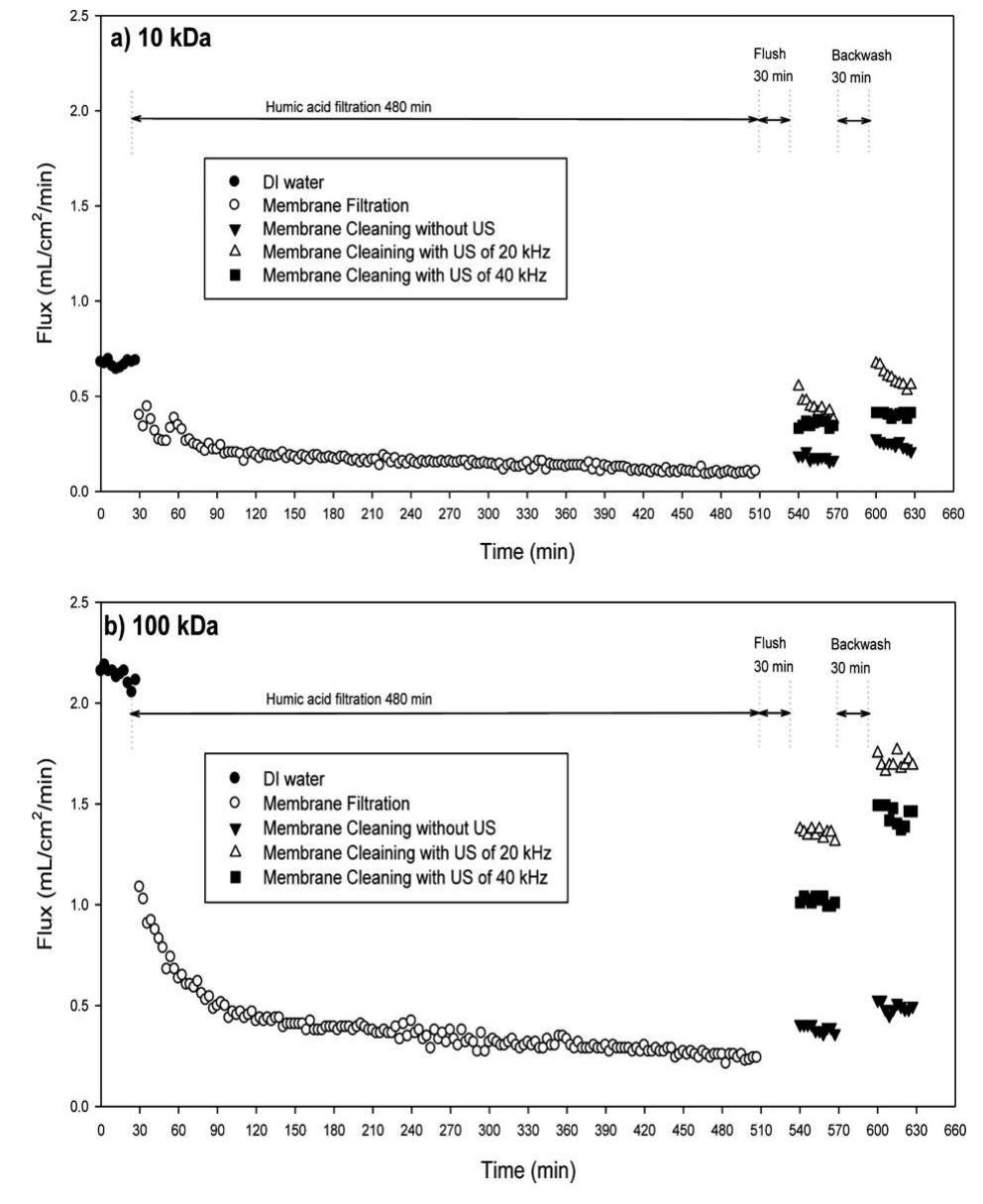

The impact of ultrasound (US) on membrane filtration and cleaning were studied and compared at various operating parameters of nominal pore sizes of 10 and 100 kDa membrane, trans-membrane pressure (TMP) of 100 and 140 kPa, and US... more

This paper deals with the problem of the colorimetric fidelity of digitised colour slides of painted works of art. A six-matrix conversion model was derived that permitted the transformation of any RGB device-dependent measurement on... more

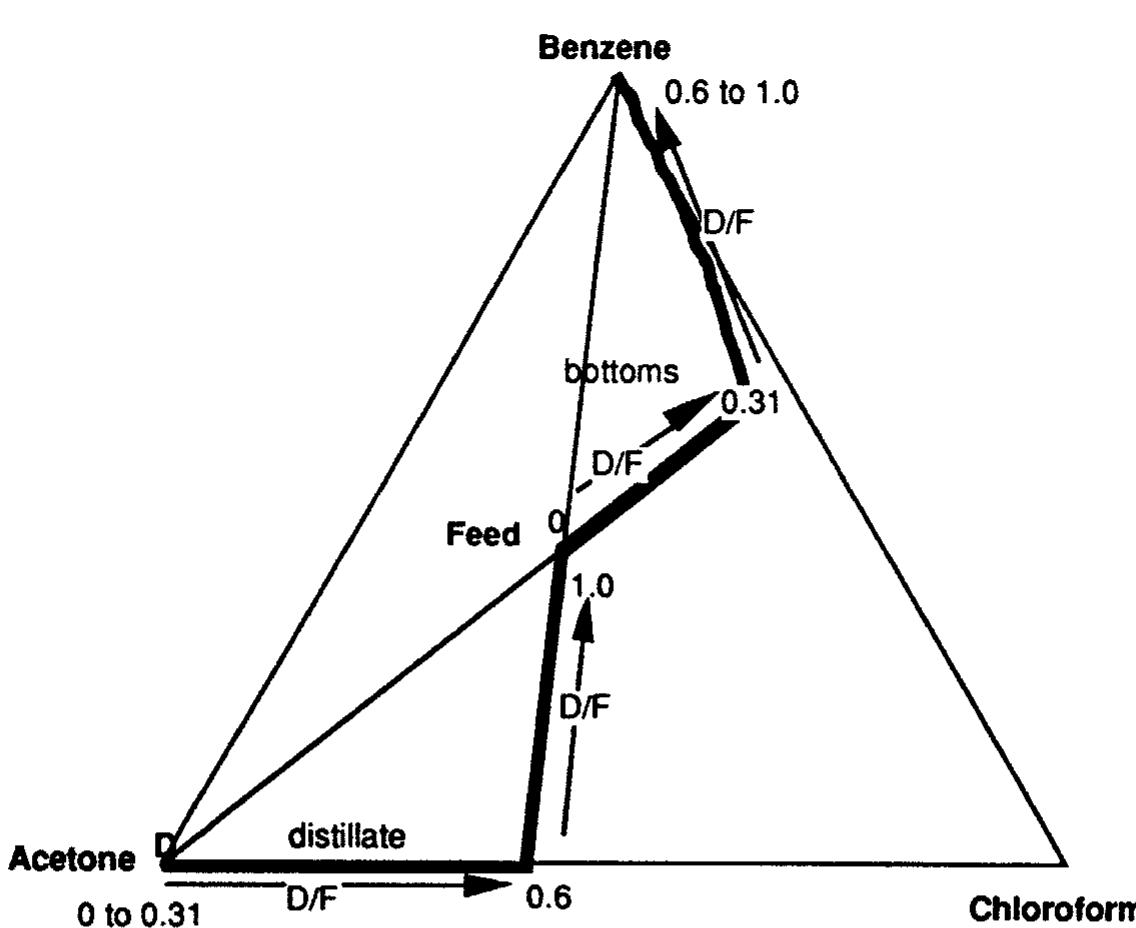

A method for systematic reactor design, described by Hillestad , is applied to the Fischer-Tropsch synthesis. The reactor path is sectioned into stages and design functions are optimized to maximize an objective function. Two different... more

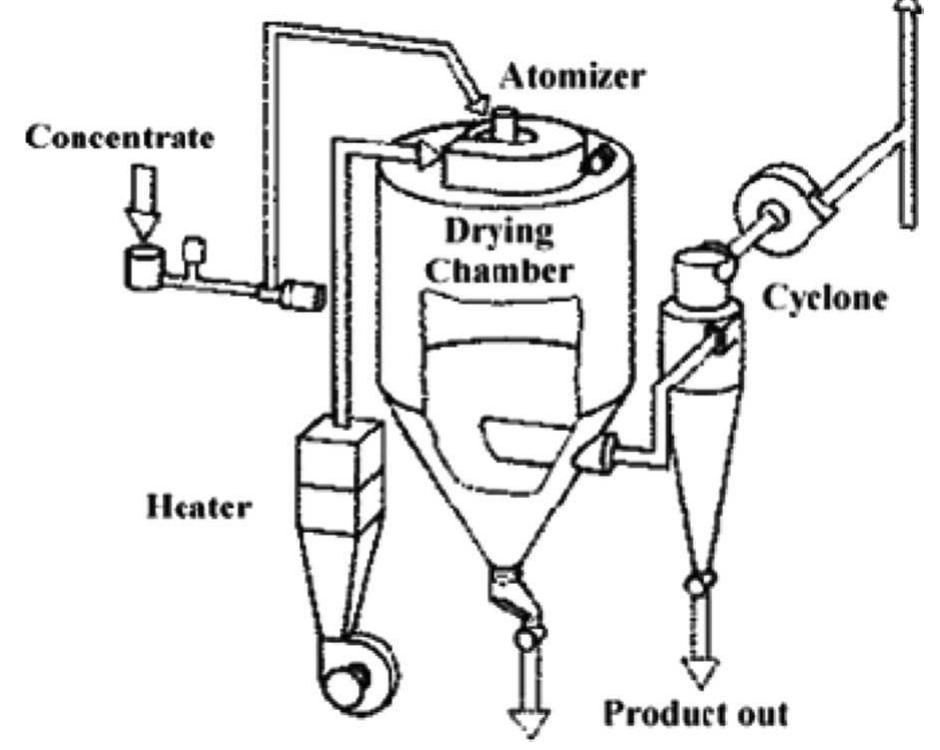

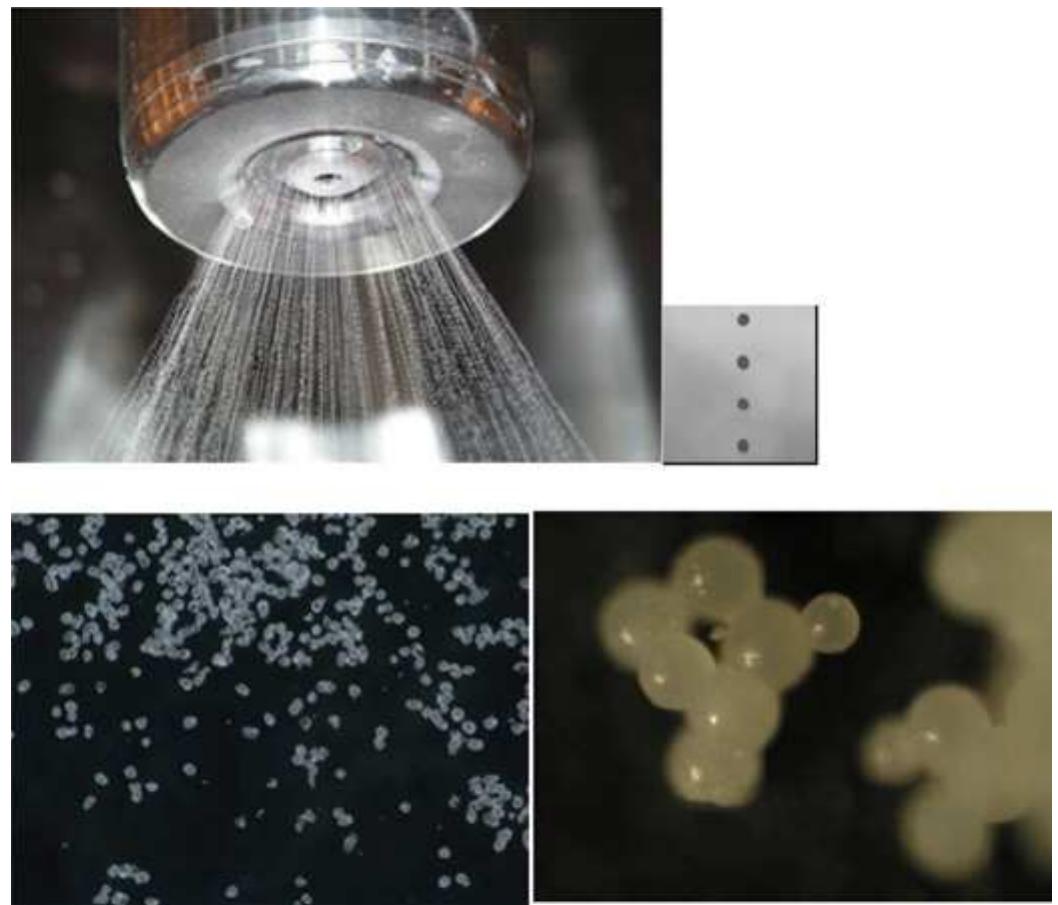

A new atomization nozzle based on ink jet technology is introduced for spray drying. Application areas are the food and dairy industry, in the first instance, because in these industries the quality demands on the final powders are high... more

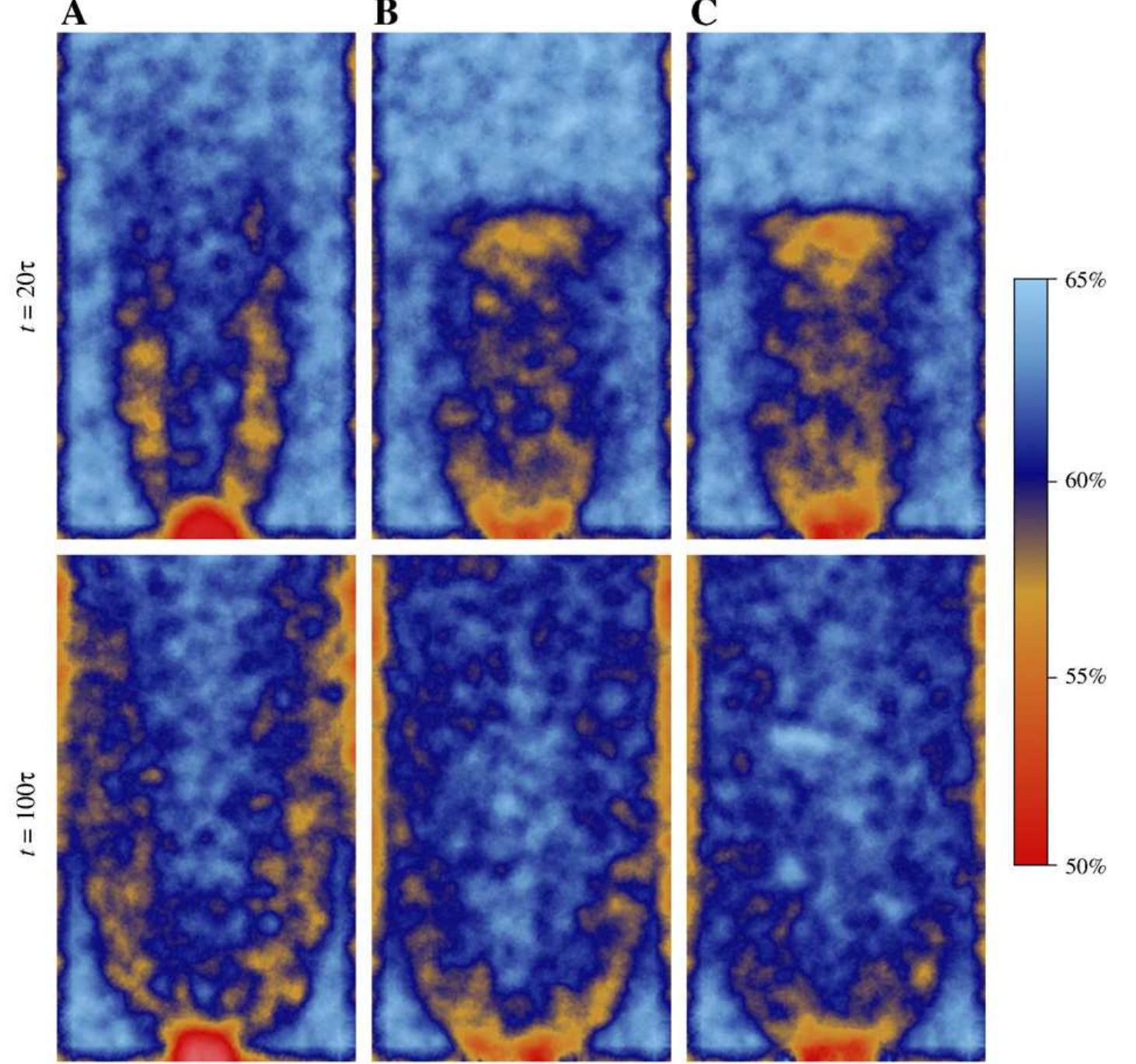

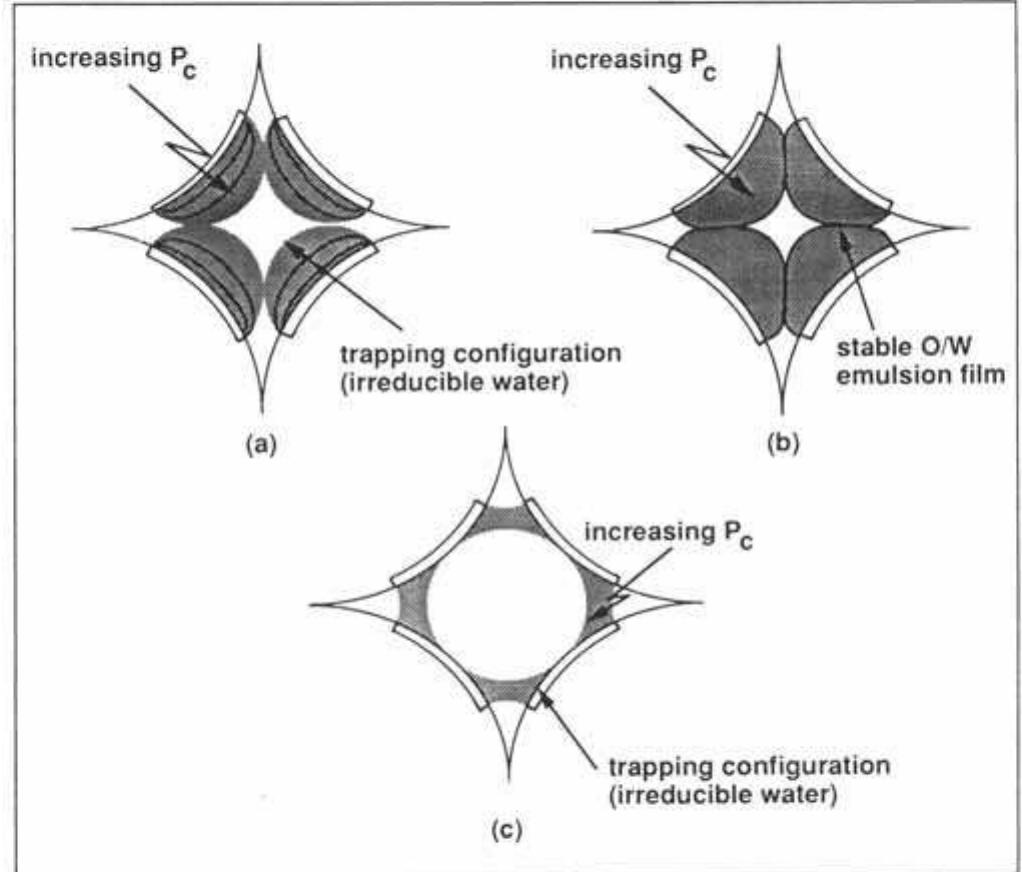

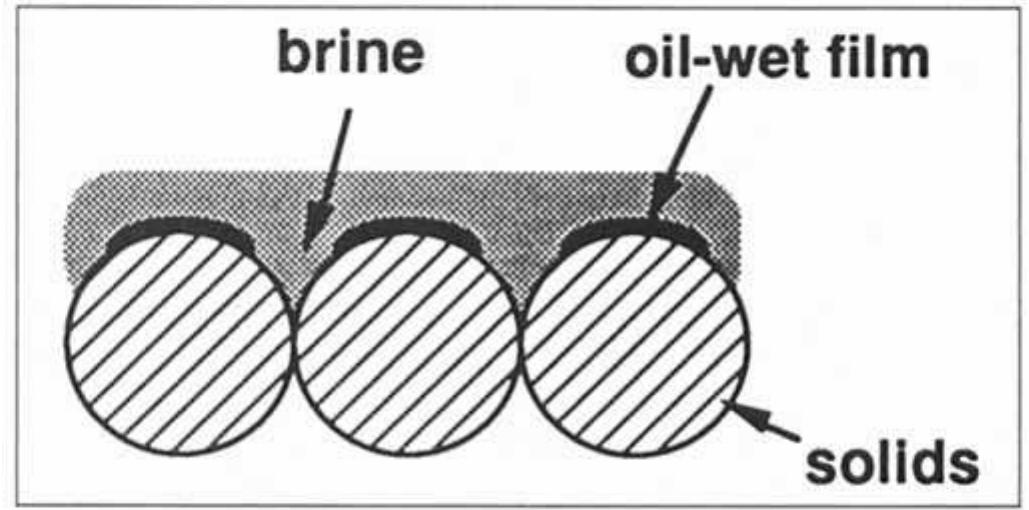

Understanding the role of thin films in porous media is vital to elucidate wettability at the pore level. The type and thickness of films coating pore walls determine reservoir wettability and whether or not reservoir rock can be altered... more

A new phthalonitrile derivative with two different substituents on 4-and 5-positions has been synthesized and its cyclotetramerization in the presence of anhydrous metal salts without any solvent resulted with phthalocyanines (4e6)... more

A new kinetic model for the fluid catalytic cracking (FCC) riser is developed. An elementary reaction scheme, for the FCC, based on cracking of a large number of lumps in the form of narrow boiling pseudocomponents is proposed. The... more

The impact of high O 2 + high CO 2 modified atmospheres (MA), on the preservation of minimally processed carrots was studied. A combination of 50% O 2 + 30% CO 2 prolonged the shelf life of sliced carrots compared to storage in air by 2... more

The kinetics of abiotic oxidation in the dark and the kinetics of biological mineralization in soil and in a compost environment of thermally oxidized LDPE were studied. It was demonstrated that different activation energies are obtained... more

Novel high hydroxyl number and high functionality polyols were developed using thiol-ene reaction of castor oil with mercaptoethanol or mercaptanized castor oil with allyl alcohol (by photochemical reaction) and 2-hydroxyethyl acrylate... more

High-titanium slag can be oxidised by exposure to oxygen or water vapour, since the slag contains trivalent titanium and divalent iron; such oxidation is used in slag upgrading processes. The presence of water vapour may increase the rate... more

Low-temperature plasma physics and technology are diverse and interdisciplinary fields. The plasma parameters can span many orders of magnitude and applications are found in quite different areas of daily life and industrial production.... more

Nanotechnology has made great strides forward in the creation of new surfaces, new materials and new forms which also find application in the biomedical field. Traditional biomedical applications started benefiting from the use... more

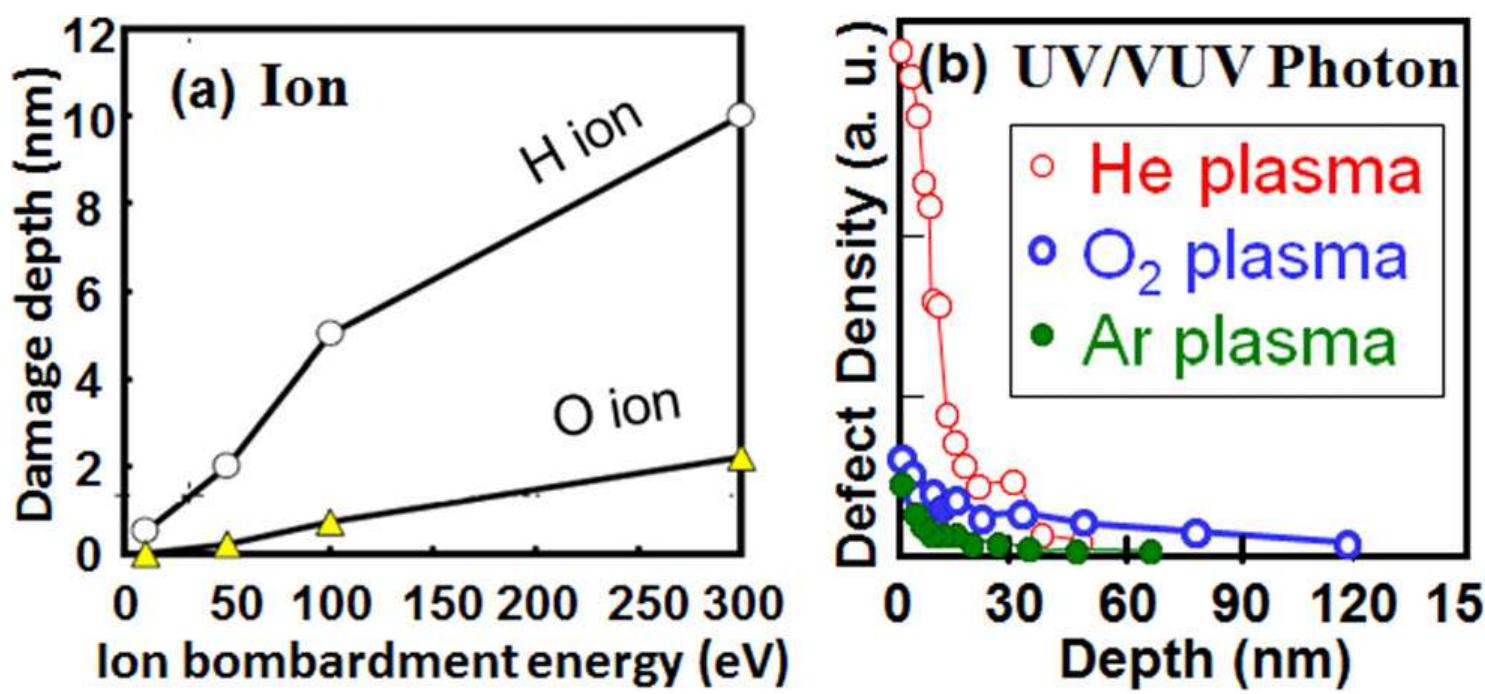

Plasma-substrate interactions in diamond synthesis via microwave plasma-assisted chemical vapor deposition (CVD) are an important issue in CVD reactor optimization. The hot spot formation observed during single-crystal diamond synthesis... more

This article models bubble removal in centrifugal casting of the thermosetting silicone polydimethylsiloxane (PDMS). Given spin speeds, mold geometry, and resin properties for centrifugal casting, it is possible to predict the amount of... more

CITATIONS 15 READS 342 4 authors, including: Some of the authors of this publication are also working on these related projects: Changes in the structural properties during osmotic drying: Relationship with mass transfer and retention of... more

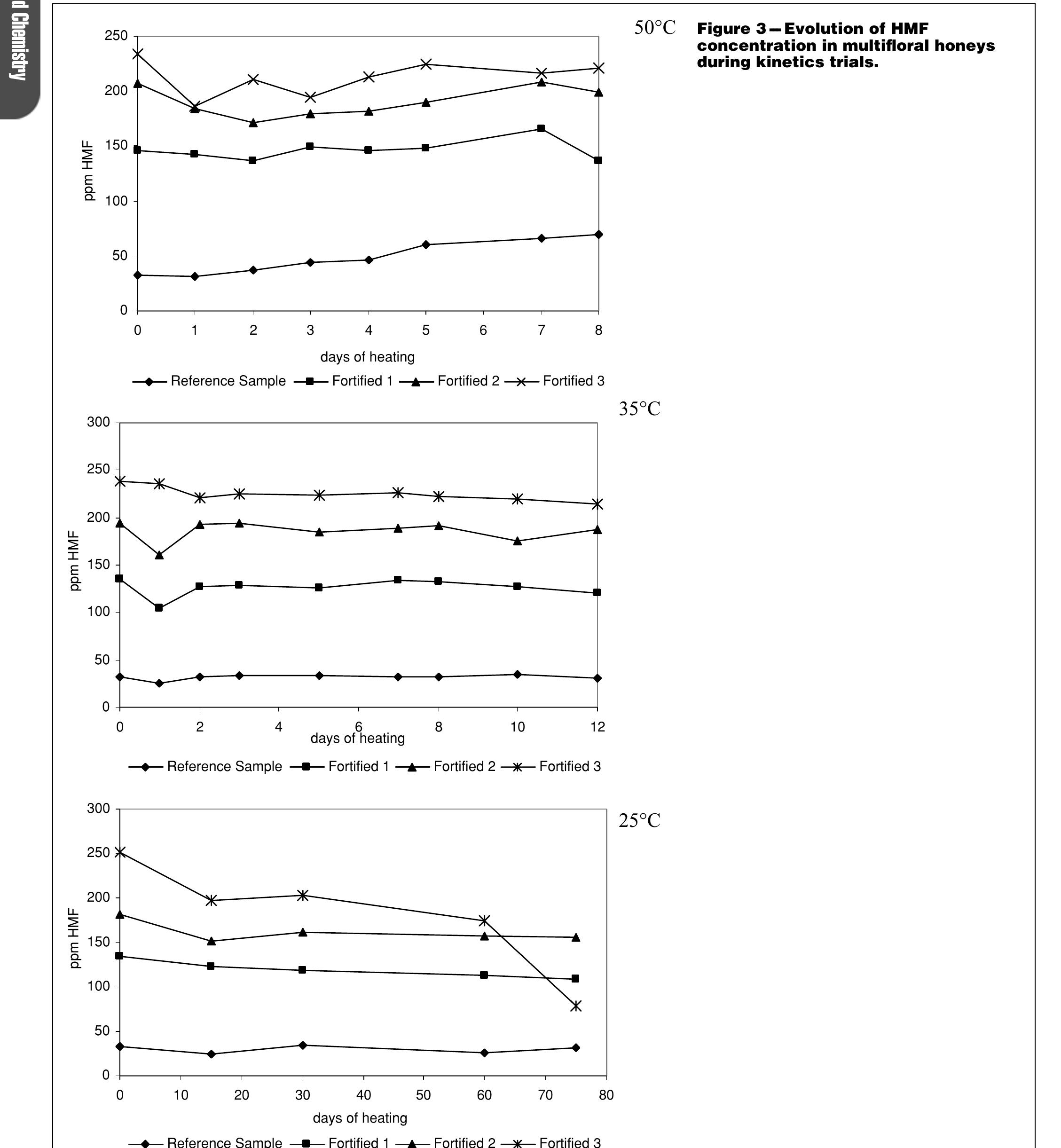

5-Hydroxymethylfurfural (HMF) is the most important intermediate product of the acid-catalyzed dehydration reaction of hexoses and/or Maillard reaction; furthermore, it is the most used index to evaluate thermal damages or ageing in food... more

Extrusion-based bioprinting (EBB) is a rapidly growing technology that has made substantial progress during the last decade. It has great versatility in printing various biologics, including cells, tissues, tissue constructs, organ... more

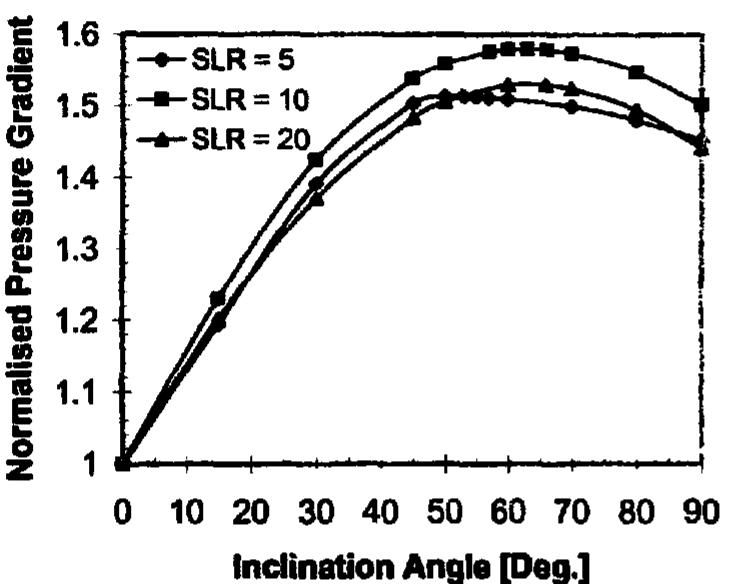

An analytical model for gas-solid suspension flow through an inclined section of pipe was developed. This model predicts the ratio of the total pressure drop in an inclined pipe to that of a horizontal pipe. The model has been used to... more

Tin oxide (SnO 2 ) is considered a very promising material as a high capacity Li-ion battery anode. Its adoption depends on a solid understanding of factors that affect electrochemical behavior and performance such as size and... more

The effects of an organic additive, polyoxyethylene sorbitan trioleate (Tween 85), on the induction time for the precipitation of calcium carbonate are experimentally and theoretically investigated. Calcium carbonate was precipitated from... more

The results of a set of experiments that were designed to integrate current knowledge on the major constituents of sugarcane bagasse lignin, specifically p-coumaric, ferulic, syringic acids, and vanillin are presented. These aromatic... more

Effects of activated carbon in a carbon-coated alumina (CCA) support, active phase morphology and its composition of Ni 6 -PW 12 S/C x /Al 2 O 3 catalysts in hydrotreating of model compounds were studied. The catalysts were synthesized... more

A large number of products, both natural and synthetic, have been and are used for the consolidation of flaking or fragile paint layers occurring on paintings, polychrome sculpture, furniture and other cultural objects. Most products in... more

Nanocomposite films based on poly(lactic acid)-poly(hydroxybutyrate) (PLA-PHB) blends and synthesized cellulose nanocrystals (CNC) or surfactant modified cellulose nanocrystals (CNCs), as bio-based reinforcement, were prepared by melt... more

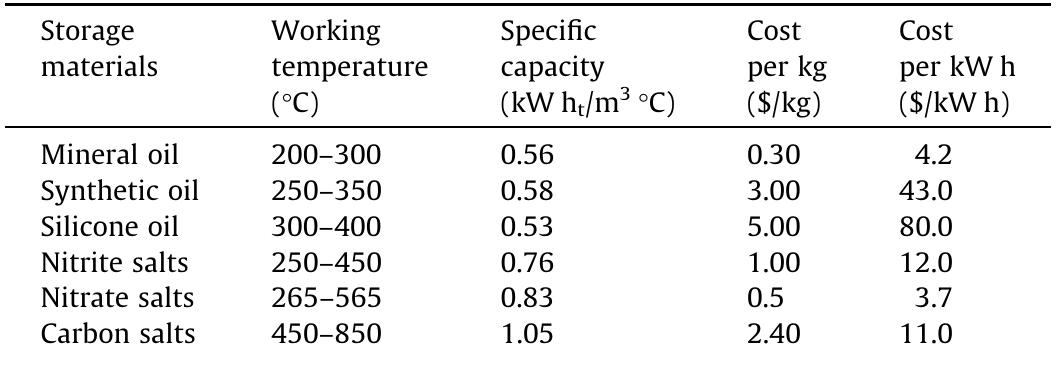

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must... more

Effect of the Addition of Membrane Processed Olive Mill Waste Water (OMWW) to Extra Virgin Olive Oil

Modern membrane technologies are useful for enhancing the concentration of phenolic antioxidants in olive mill waste water (OMWW) to produce concentrates with valuable applications in functional foods. Three types of OMWW concentrates,... more

The 2.05 Ga Bushveld Complex in South Africa, host to many lucrative ore deposits, is surprisingly pristine and unaltered given its geological age. In some areas, however, there is evidence of low temperature weathering, alteration and... more

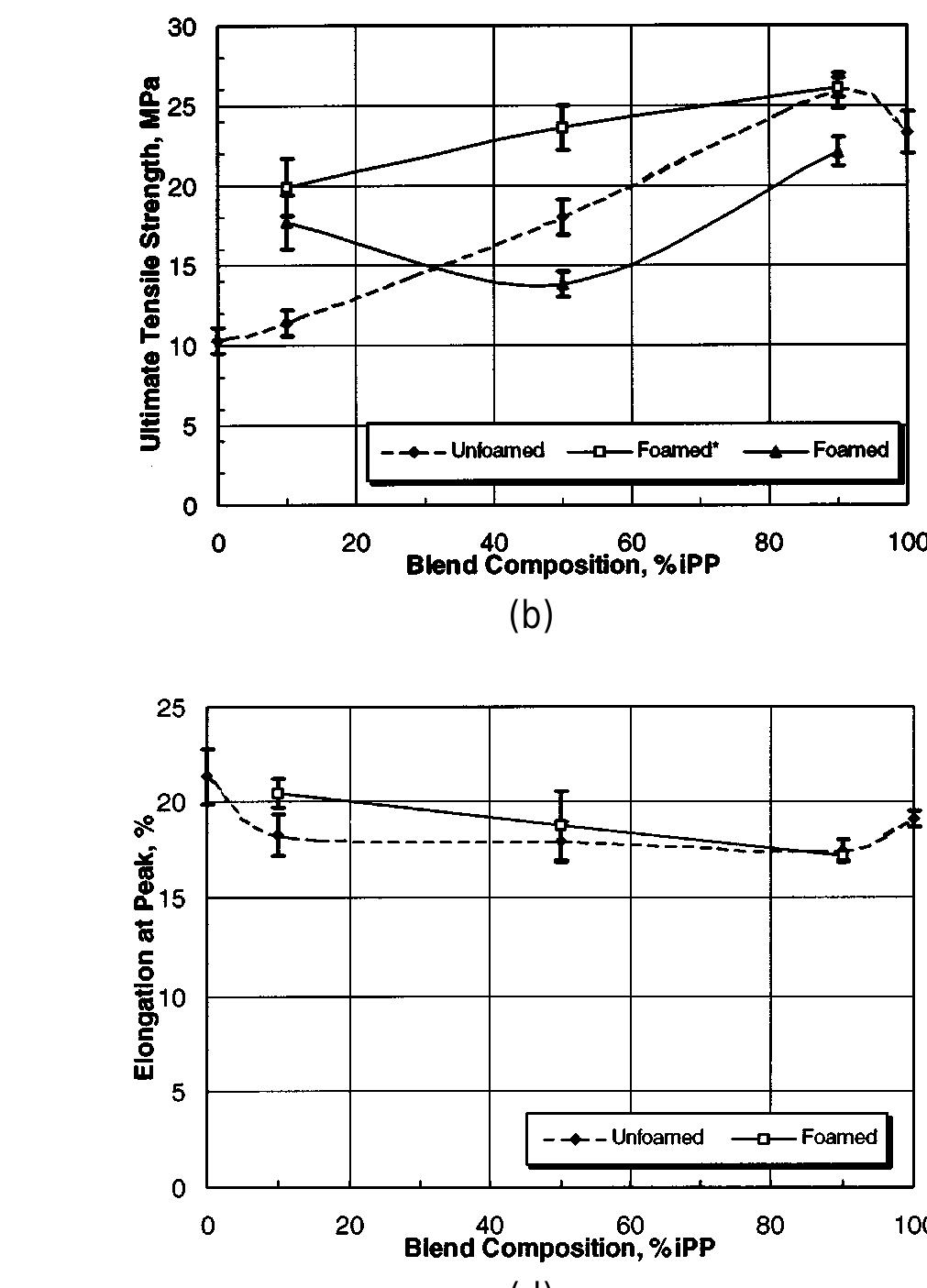

In this paper, a study on the batch processing and characterization of microcellular foamed high-density polyethylene (HDPE/iPP) blends is reported. A microcellular plastic is a foamed polymer with a cell density greater than 109... more

Microgreens have gained increasing popularity as food ingredients in recent years because of their high nutritional value and diverse sensorial characteristics. Microgreens are edible seedlings including vegetables and herbs, which have... more

The aim of the study was to obtain high quality biodiesel production from a microalga Chlorella protothecoids through the technology of transesterification. The technique of metabolic controlling through heterotrophic growth of C.... more

Recent observations suggest that increased silicon levels improve ladle desulfurization of aluminum-killed steel. A kinetic model was developed and presented in part I of this paper, demonstrating that increased silicon levels in steel... more

AbstrAct It is a current concern in the wood preservation field to avoid the use of toxic chemicals and develop new technologies based on low environmental impact agents and sustainable principles. Under this expectation, an intended... more

The performance and membrane fouling of a lab-scale submerged sponge-membrane bioreactor (Sponge-MBR) and a conventional MBR were investigated and compared for hospital wastewater treatment at low fluxes of 2-6 LMH. COD removal by the... more

The indium foil activation technique has been employed to measure thermal neutron fluences (F th ) among various locations in the treatment room with a 20 Â 20 cm 2 field size and a 15 and 10 MV X-ray beam. Spatial F th are visualized... more

![Fig. 1. The mechanism for structural rearrangement in the spot model. The random displacement of a diffusing spot of free volume (dashed circle) causes affected particles to move as a block by an amount (A), followed by a relaxation under soft-core repulsion forces (B); the net co-operative motion combines these two steps (C). (Particle displacements are exaggerated for clarity.) Fioure from Ref [22].](https://figures.academia-assets.com/47641182/figure_001.jpg)

![Fig. 4. Snapshots of (A) DEM simulation, (B) a spot simulation using a random walk with simple biasing, (C) a spot simulation using simple biasing and influence weighting, and (D) spot simulation using adapted biasing (with (= 3) and influence weighting. The snapshots are taken at t= 300r. A further modification to the spot model can be employed to correct for this. In the previous implementation, when a spot moves by VV, then the particles experience a displacement —Vv/w, where w is a fixed quantity. Suppose that a spot is going to influence p particles, each of volume V,,. If spots are thought of as carrying a completely fixed amount of free volume V,, then another possible approach would be to let w=pV,/Vs, so the spot's influence is divided equally among the parti- cles in range. In the bulk, where the particles are roughly at constant In the void model, the evolution of the free surface has been addressed by making use of a very simple modification of the random walk process [11]. In the bulk of the packing, when a void generally has two particles in the lattice points above it, the void moves to each of these sites with equal probability. However, in the case when only one of these two sites is filled with a particle, the void always moves in](https://figures.academia-assets.com/47641182/figure_004.jpg)

![(a) The parameters used in the DEM simulation. (b) The five parameters used in the spot model simulations that were fitted from DEM simulation. All values are taken from Ref. [22]. The spot simulation was implemented in C++, with the main routine being written as part of a class that represents the entire simulation domain. For efficiency, the class divides the simulation up into a rectangular subgrid of regions, and keeps a separate list of position vectors of particles within each region. When particles are added to the container, they are sorted into the correct region. Two key routines are used to implement the spot microscopic mechanism. The first, spot (pV rs) applies the spot motion, by displacing all particles within a distance r, of p’ by an amount V. Table 1](https://figures.academia-assets.com/47641182/table_001.jpg)

![FIGURE 1. (A) Polarization curves in RDE at 1500 rpm. O»-saturated electrolyte of pH 1 at 20 °C. NNMC loading of 800 ug cm * except UK63-65 (460 wg cm”) and CoTMPP700 (306 wg cm’). Curve a: Pt/ C, 302 wg of Pt cm? (355 ug of C cm ”). Curve b: NNMC target for year 2010 for a loading of 460 wg cm’. Other curve labels are 1 (UK63), 2 (UK65), 3 (FC 280), 4 (M786), 5 (DAL900C), 6 (COTMPP700), 7 (GAdFeCu), 8 (DAL900A), and 9 (CHb200900). (B) Tafel plots (E vs log Iy) in RDE. Same conditions as those in part A. Curve a: 46% Pt/C. Curve b: NNMC target by U.S. DOE for year 2010. For curve a, the Pt activity is as defined by eq II [A (g of C) ' contained in Pt/C].](https://figures.academia-assets.com/43564385/figure_001.jpg)

![FIGURE 3. Tafel plots of the various NNMC cathodes in a PEMFC. NNMC loading 1 mg cm. Naf/Cat = 2. Curve a: 46% Pt/C; 0.33 mg of Pt cm ?; Naf/Cat = 2. For curve a, the Pt activity is as defined by eq II [A (g of C)' contained in Pt/C]. Curve b: estimated target activity for NNMC for year 2010 (see the Supporting information, section D).](https://figures.academia-assets.com/43564385/figure_003.jpg)

![Scheme 1. Patterning process of two-layer system. N,N-Dimethylacetamide (DMAc) was purified by vacuum distillation. 4,4’-Oxydianiline (ODA) purchased from Tokyo Chemical Industry Co., Ltd (TCI) was recrystallized from tet- rahydrofuran (THF) under nitrogen. 3,3’,4,4’-Biphenyltetra- carboxylic dianhydride (BPDA) purchased from TCI was dried in vacuo at 180 °C for 12 h before use. The 9,9-bis(4- tert-butoxycarbonyloxypheny]l)fluorene (t-BocBHF), TBMPF and PHA derived from 4,4’-(hexafluoroisopropylidene)- bis(o-aminophenol) and 4,4’-oxybis(benzoic acid) deriva- tives were prepared as described previously [17,24]. The number- and weight-average molecular weight (M, and Firstly, the PAA solution is spin-coated on a silicon wa- fer and baked in the usual way. Then, the thin layer of PSPBO consisting of PHA, TBMPF and PTMA is formed onto the thick PAA film and dried by pre-baking. This film is ex- posed to UV light to generate propanesulfonic acid from PTMA. Upon post-exposure bake (PEB) treatment of the film, the acid deprotects the tert-butyl ester of TBMPF](https://figures.academia-assets.com/70360709/figure_001.jpg)

![concentration of CO) at the end of the path is 34.81%. This will increase H,/CO at the end of the reactor path to 5.33. The optimal mixing structure is plug flow [12].](https://figures.academia-assets.com/45642159/figure_003.jpg)

![Staging with optimal distribution of heat transfer area, dis- tribution of syngas, and mixing configuration will increase the profit measure as demonstrated here. The results of this study can serve as initial points for staging of the FT reactor in the overall GTL process with different syngas production config- urations [23].](https://figures.academia-assets.com/45642159/figure_005.jpg)

![Table 1. Kinetic and adsorption parameters in Eqs. (2) and (3) [2].](https://figures.academia-assets.com/45642159/table_001.jpg)

![relatively sharp absorption peaks and almost no shoulder on the higher energy side, which would correspond to aggregated species [5,16,34,35]. There is almost no appreciable change in the molar absorptivities of the Q bands in the concentration range of 10-°—-10-° M. The metal-free phthalocyanine (10) gives doublet Q band in the visible region (684 and 718 nm) as a result of the D2, symmetry [5,35]. When compared with diethylmalonate and chlorine substituted derivatives re- ported earlier, substitution of chloro-group with alkylsulfanyl moiety leads to a shift of 17—19 nm to longer wavelength and it might be important to bring a new approximation for tuning the optical properties of phthalocyanines.](https://figures.academia-assets.com/45114819/figure_002.jpg)

![Figure 3. Technology roadmap of CVD for realizing an ultimate functional device. (Picture of carbon nanowalls as an example for self-assembling material synthesized by CVD [21].).](https://figures.academia-assets.com/33964799/figure_003.jpg)

![The second main challenge is the understanding of the physical and chemical processes occurring at the plasma— liquid interface (see also figure 9). The liquid interface can be an important heat sink. In fact, very strong temperature gradients are observed at the plasma—liquid interface and it remains to be seen if a real connection between plasma at Electrical breakdown and ionization in liquids have been investigated for several years. Ionization mechanisms in relatively basic liquids such as liquid Ar are well understood [48]. Although it is generally assumed that breakdown in water Figure 8. Upper drawings present three basic configurations of PLs. The corresponding figures below are a typical image of the discharg generated in the above configuration. (a) Direct filamentary (microsecond pulsed) discharge in water, (b) dc excited glow discharge (in ai with water cathode and metal anode and (c) (nanosecond pulsed) discharge in (Ar) bubbles in water.](https://figures.academia-assets.com/33964799/figure_008.jpg)

![Figure 9. Schematic overview of some important transfer processes at the plasma-liquid interface. Note that some processes are polarity dependent. More details can also be found in [47] and references therein.](https://figures.academia-assets.com/33964799/figure_009.jpg)

![Figure 12. Time evolution of species during the low-temperature plasma reduction of a NiO—Al,O; catalyst to Ni by CH, ina dielectric barrier reactor at atmospheric pressure. Reproduced from [70] by permission of Elsevier Ltd. Figure 11. Schematic representation of the way in which plasma catalysis involves both effects of the plasma on the catalyst and the catalyst on the plasma. Adapted from [66].](https://figures.academia-assets.com/33964799/figure_011.jpg)

![Figure 13. Calculated isotherms in gas—metal arc welding arc and electrodes, including (left) and neglecting (right) the influence of aluminium vapour from the electrodes, for the welding parameters used in [80].](https://figures.academia-assets.com/33964799/figure_013.jpg)

![Figure 14. Temperature distributions measured by emission spectroscopy in a cross-section of an argon plasma jet at four times, each separated by 2.14 ws. From [87].](https://figures.academia-assets.com/33964799/figure_014.jpg)

![Figure 16. [93] Specific energy requirement (SER) of H.S dissociation as a function of specific energy input (SED) for different discharges (including microwave (MW) and Gliding Arc in Tornado (GAT)) and thermodynamic equilibrium model under absolute quenching assumption. Figure 15. Variations of pH of deionized water after DBD plasma treatment in three different gases [95].](https://figures.academia-assets.com/33964799/figure_015.jpg)

![Figure 17. Quantitative data concerning decrease in induction delay time by pulsed nanosecond discharge in a combustible mixture (reference [Kosarev2009] from [99], work of group of Starikovskii at MIPT).](https://figures.academia-assets.com/33964799/figure_017.jpg)

![Figure 18. Quantitative data concerning density of O-atoms in air and air—ethylene (ER = 0.5) mixture. TALIF measurements, P = 60Torr, nanosecond pulse energy is 0.76 mJ (according to [20] from review [101]).](https://figures.academia-assets.com/33964799/figure_018.jpg)

![Figure 22. Plasma parameters from a 3D-hybrid simulation for a streamer in air. The lines show the demarcation between regions using a fluid simulation and those using a particle simulation. (Adapted from [145].)](https://figures.academia-assets.com/33964799/figure_022.jpg)

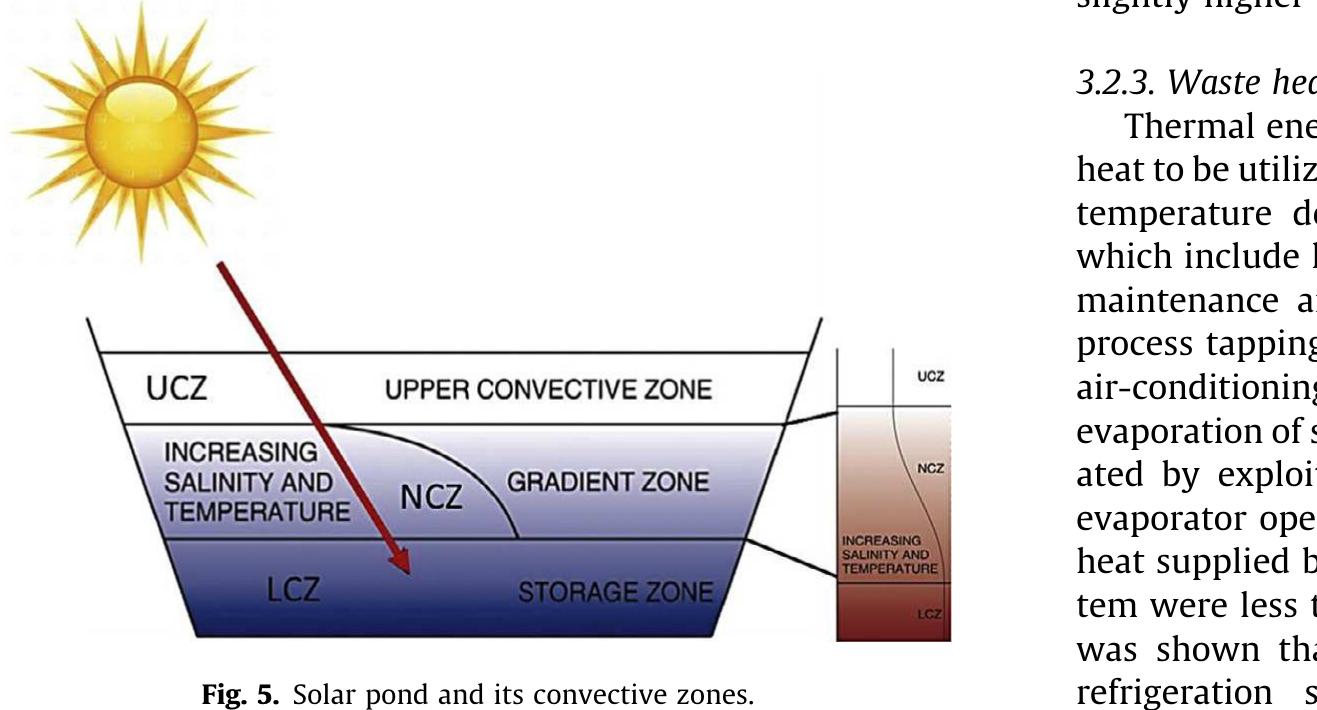

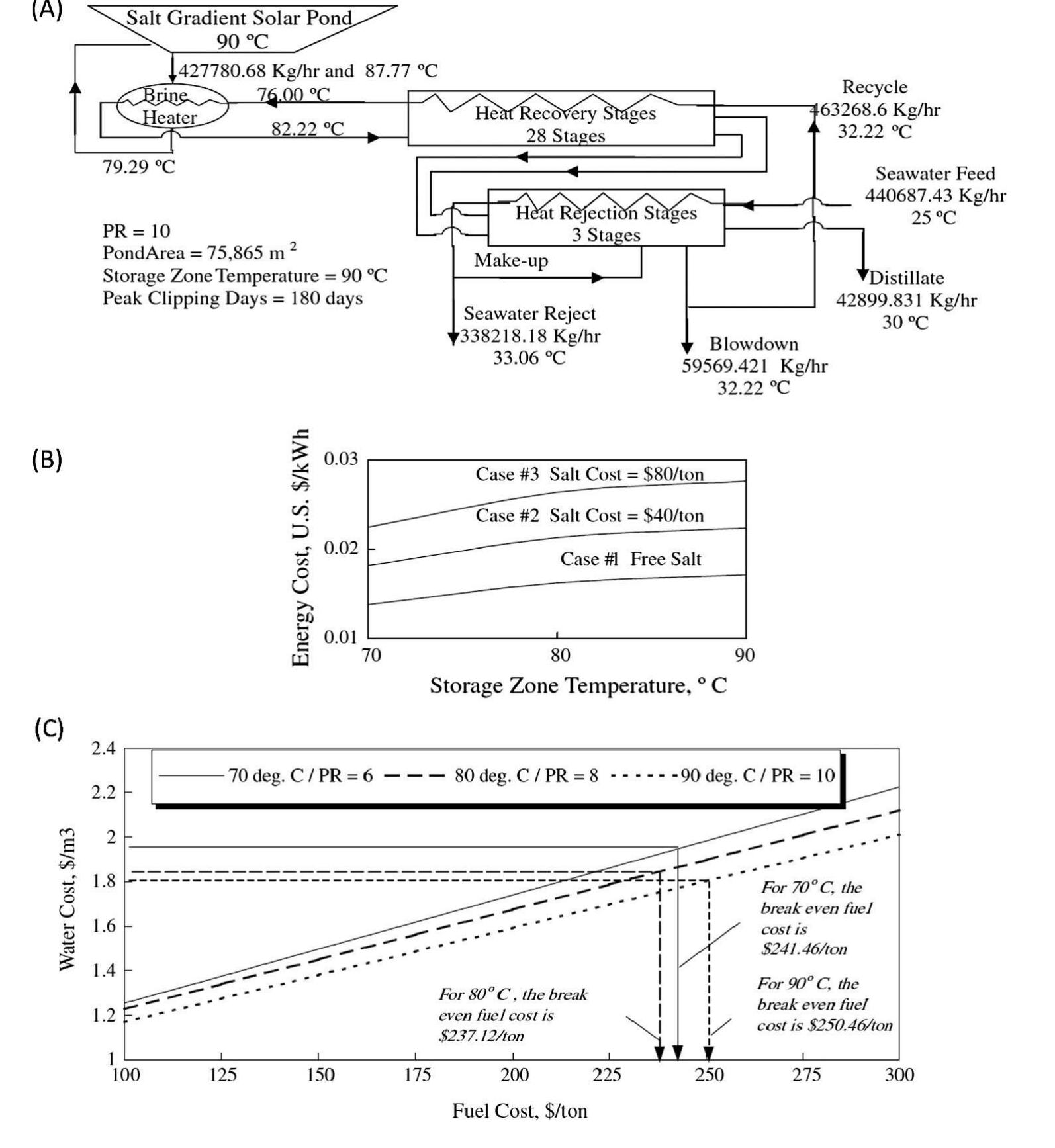

![As of June 2011, there were 15,988 desalination plants world- wide which combined produce a total of 65.2 million m? of fresh- water equivalent to 17.5 billion US gallons in over 150 countries supporting 300 million people [129]. Out of these desalination plants, reverse osmosis with about 60% share currently dominates the other desalination technologies | 133] (Fig. 2a) and this trend is expected to continue into the future followed by well-established MSF technology (26.8%) and MED technology (8%) with the remaining 5% taken by electrodialysis and other hybrid technolo- gies. Sixty percent of the desalination plants process seawater to produce freshwater (Fig. 2b) followed by brackish water (21.5%), river water (8.3%), wastewater recovery/reuse (5.7%) and other water sources (4.5%) [130]. Energy requirements for desalination technologies vary significantly in quantity and quality. Table 1](https://figures.academia-assets.com/34338939/figure_004.jpg)

![3.2.4.2. Thermal energy storage in solar desalination. Storage volume is critical to the performance of the TES tank. In desalination appli- cation powered by solar collectors, a TES tank is required to miti- gate the effects of cloudy hours and non-sunlight hours. In a recent study, the effect of TES tank volume was simulated for a low temperature desalination process (at a capacity of 100 L/d) supported by solar collectors [7]. Temperature profiles over a week of operation for the TES tank at two different volumes (1 m? and 6 m?) are shown in Fig. 8. As expected, the TES temperature pro- files followed the sinusoidal nature of the solar irradiation and the ambient temperature. Smaller TES volume (1 m?) temperatures were more responsive to these variations than higher TES volume Fig. 7. Effect of LCZ depth on the storage medium temperature profiles.](https://figures.academia-assets.com/34338939/figure_008.jpg)

![Fig. 2. Bioink types used in EBB: (A) cells loaded in hydrogels, (B) polymer micro-carriers pre-loaded with cells [63], (C) tissue spheroids made of cells and ECM [21], (D) cell pellet in nozzle tip [41], (E) tissue strands [29] and (F) dECM before loading cells [51].](https://figures.academia-assets.com/39997046/figure_002.jpg)

![Fig. 4. Bioprinting of vascular and vascularized tissue constructs: (A1) photograph of bioprinted agarose hydrogel filaments representing branched vascular network in a GelM/ hydrogel block and (A2) a high resolution cross-sectional view of GelMA block stained for live and dead cells (reproduced/adapted with permission from Ref. {25]); (B1) sprouting o endothelium (stained with red fluorescent protein) into capillary network (stained with green fluorescent protein) within fibrin gel on day 9 and (B2) a high resolution image of th capillary network on day 14 (reproduced/adapted with permission from Ref. [197]); (C) an image acquired during evacuation of the fugitive ink showing channels in GelMA scaffolt (upper-left) which were later glued with 10T¥ fibroblasts, HUVECs and human dermal fibroblasts (HUDFs) (reproduced/adapted with permission from Ref. |27]); (D1) a scannin, electron microscopy image of directly bioprinted vascular channels embedded in a large alginate construct (D2) showing L929 mouse fibroblasts in green (reproduced/adapted wit! permission from Ref. | 190]); (E1) scaffold-free bioprinting of a branched vascular network using 300 um human skin fibroblast (HSF) spheroids (solid and broken arrows show 1. and 0.9 mm in vascular diameter, respectively), where spheroids (E2) fuse and maturate into tissue after 6 days of deposition (reproduced/adapted with permission from Ref. [21}) (F) fabrication of a perfusable tissue via integration of bioprinted vasculature and fibroblast tissue strands (reproduced/adapted with permission from Ref. [29]), the scare ba corresponds to 2 mm on the right figure. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)](https://figures.academia-assets.com/39997046/figure_004.jpg)

![Fig. 6. 3D printed cyborg ears: (A) bioprinting of anatomically correct cartilage scaffold loaded with chondrocytes along with printing of coil antenna; (B) scaffolds were cultured 10 weeks, resulting in neocartilaginous tissue in alginate matrix, (C) 3D printed complementary ears (right and left) demonstrated the ability to listen to stereophonic audio music (reproduced/adapted with permission from Ref. [218)}). Due to its unique capabilities, EBB has been preferred for fabrication of living tissues and organs, and regulatory issues seem to be down the way as the technology transforms into products for clinics and human-use purposes. Currently, there is no regulations that has been laid down for bioprinting including bioink, bio- printers and bioprinted products such as tissues, and FDA has not imposed any regulatory restrictions on bioprinting technology yet. Cutting-edge technologies such as bioprinting cannot be easily categorized for regulatory purposes while it does not fit into the general classification of “device”, “drug” or “biologic” under FDA regulations. Office of Combination Products (OCP) formed by FDA can handle this situation, where “combination product” is defined in 21 CFR §3.2(e) as “A product comprised of two or more regulated components, i.e., drug/device, biologic/device, drug/biologic or drug/device/biologic, that are physically, chemically, or otherwise combined or mixed and produced as a single entity” [221]. The OCP does not conduct product reviews but assigns combination prod- ucts to the appropriate FDA center (i.e., the Center for Drug Eval- uation and Research (CDER), The Center for Biologics Evaluation One of the major shortcomings of EBB is the lack of high- resolution systems due to the nature of the extrusion process it- self. Although certain errors can be induced due to other system components, such as errors associated with the motion system or the extrusion process itself has an enormous contribution to the low resolution. Although very small nozzle tips can be considered possible, decreasing the nozzle size results in a considerable increase in the shear stress and corresponding cell damage and death. Thus, EBB systems should be modified to alleviate this issue. In addition, lowering the size further increases issues such as nozzle clogging and the need for elevated dispensing pressure levels. Although a low electric field can be applied to reduce the size of the printed fila- ments as widely used in electrohydrodynamic printing [53], cells should be kept away from the electric field to safely deliver them. A recent approach in the application of electrohydrodynamic jetting in inkjet-based bioprinting demonstrates the safe usage of the system with cells; this approach has the potential to be used in EBB [54]. The other potential of increasing the resolution is to use a cone-shaped nozzle (i.e., Taylor cone or regular cone) that has a relatively allevi- ated shear stress, which reaches its maximum at the end of the nozzle tip, affecting cells at a minimum duration. In addition to these approaches, a highly innovative approach might be using a nozzle- free extrusion system that enables the bioink to overcome surface- tension-induced droplet formation.](https://figures.academia-assets.com/39997046/figure_006.jpg)

![Fig. 1. Tensile test results of PLA, PLA-PHB and nanocomposite films: a) Stress-strain curves, b) Young's Modulus (E), c) Tensile strength (TS) and d) Elongation and break (eg) a-dpifferent letters on the bars within the same image indicate significant differences between formulations (p < 0.05). The estimated viscosity molecular weight (My) of PLA and PHB pellets were 95,800 + 4400 g mol” !and 255,300 + 39,000 g mol" !, respectively. It is know that polymers can undergo thermal degradation during processing and diminution of My values for all film formulations with respect of PLA pellet and/or PHB pellet were detected (Table 1). PLA processed into film resulted in a reduction of the M, of PLA around 5%. Further decrease occurred in binary PLA based nanocomposites. While, a reduction of PLA M, value of 10% was detected for PLA-CNC, PLA-CNCs showed a higher reduction of 15%. This results is in accordance with previous work where we showed that the thermal stability of PLA was reduced with the addition of cellulose nanocrystals, particularly for PLA-CNCs [25]. As it can be seen from tensile curves (Fig. 1-a), the neat PLA film showed a characteristic plastic deformation that it was reduced with both, PHB and CNC incorporation. CNC and PHB proved to be effective to increase PLA modulus (Fig. 1-b), but no significant differences were observed between the Young's modulus of PLA-CNCs and PLA films. While CNCs or PHB produced a decrease on the tensile strength (TS) of PLA, the combination of PHB and CNCs produce a nanocomposite (PLA-PHB-CNCs) with comparable TS with respect to PLA. This behaviour can be related with the more efficient dispersion of functionalized cellulose nanocrystals (CNCs) [3] resulting in an enhancement in the interfacial adhesion and therefore in a better interaction between PLA and PHB [25]. Moreover, the PLA-PHB-CNCs film revealed the highest deformation at break, showing an increase of 175% with](https://figures.academia-assets.com/43362038/figure_001.jpg)

![Fig. 3. a) Visual appearance of film samples before and after different incubation days under composting conditions. b) Degree of disintegration of films under compostin; conditions as a function of time. Additionally, films for food packaging are required to protect foodstuff from humidity during transport, handling and storage. Thus, water contact angle measurements were carried out to evaluate the hydrophilic/hydrophobic character of films and the results are shown in Fig. 2(c) [37]. It should be noticed that all formulations showed values higher than 65°, being materials acceptable for the intended end-use applications. PHB has a hy- drophobic character due to the poor affinity of the water to the non- polar polymer surface [38]. In this way, the PLA-PHB blend showed significant increased water resistance in comparison with neat PLA, in good accordance with a previous reported work [12]. The pres- ence of CNC in PLA and PLA-PHB caused an increase in wettability, while functionalized CNCs did not significantly change PLA or PLA- PHB wettability. The positive effect of cellulose nonocrystal chemical modification in the wettability of PLA and PLA-PHB films is mainly due to the presence of sulphate groups with low polarity on the surface that increase the surface hydrophobicity of the final material. Fig. 3 (a) shows the visual appearance of PLA, PLA-PHB and cellulose nanocrystal based nanocomposites after different time of disintegration in composting conditions where it is possible to confirm the biodegradable character of all the formulations stud- ied. After only 1 day of incubation, films become smaller, with the exception of PLA-PHB blend, which started the film size reduction on the second day of incubation. After 7 days of incubation binary and ternary formulation films became breakable and small pieces of films were recovered. It also could be noticed that they changed their colour and became more opaque after 7 days. When the degradation process of the polymer matrices started, a change in the refraction index of the materials was observed as a result of water absorption and/or presence of products formed by the hy- drolytic process [39]. Additionally, the films disintegrability was evaluated in terms of mass loss as a function of incubation time (Fig. 3 (b)), in which the line at 90% of disintegration represents the goal of disintegrability test [4]. Unmodified cellulose nanocrystals (CNC) speed up the disintegration of PLA and PLA-PHB blend from 14 days to 21 days, respectively, to 10 days. Comparable findings were previously reported for PLA nano-biocomposite films with functionalized cellulose nanocrystals and silver nanoparticles [40]. Accordingly, after 10 days CNC incorporated films were visibly disintegrated (Fig. 3 (a)), while CNCs incorporated counterparts reached between 50 and 60% of disintegrability and need 14 days to reach the goal of the disintegrability test (Fig. 3 (b)). Itis known that](https://figures.academia-assets.com/43362038/figure_003.jpg)

![Fig. 5. Optical micrographs (20x) of PLA, PLA-PHB and nanocomposite films and their EDF-z profiles. Fig. 7(a) shows the typical Py-GC/MS chromatogram of PLA- PHB-CNCs obtained by pyrolysing the film at 1000 °C for 0.5 s. The pyrolysis of all PLA based films is characterized by the presence of two peaks with very similar mass spectra (m/z = 32, 43, 45 and 56) in which the peak at 17 min corresponds to meso-lactide and the peak at 18 min with the highest signal intensity in all samples to (L) and/or (D)-lactide [32]. Films with PHB showed the broad peak The chemical changes of nanocomposite films before and after 1, 2 and 3 days in composting were followed by FTIR analysis. At](https://figures.academia-assets.com/43362038/figure_005.jpg)

![of crotonic acid (6.7 min, m/z = 39, 41, 68, 69, and 86) [12,36], while nanocomposte films showed a peak at 22.5 min assigned to thermal degradation products of the cellulose structure (m/z = 55, 69, 87 and 103) [47]. The groups of small peaks appearing at retention times between 19 min and 22 min were assigned to the thermal degradation products of PLA with the characteristic series of signals at m/z = 56 + (n x 72) attributed to PLA degradation products such as dimers (n = 2) and trimers (n = 3) [32]. In general, the intensity of peaks decreased with composting time. However, the meso- lactide intensity showed a lower decrease with respect to the (D,L)- lactide equivalent. The ratio meso-lactide:lactide has been used as a semi-quantitative sign of the degradation of PLA [12,32,36,48,49]. ig 7(b) shows the reduction of (D,L)-lactide with respect to meso- lactide after the pyrolysis of the recovered samples. No significant differences were observed between PLA and PLA-PHB blend until 7 days in composting, but after 10 days, the PLA relationship [lactide; meso-lactide;_10 days/lactide/meso-lactide;_o days] highly decreased Nanocomposites showed similar reduction in 3 days of composting, but higher times revealed higher reduction for unfunctionalized nanocomposites (PLA-CNC and PLA-PHB-CNC). The estimated reduction of the (D,L)-lactide form with respect to the meso-lactide followed a similar tendency that the disintegrability test. In this sense, PLA-CNC and PLA-PHB-CNC showed the highest degradation rate suggestive of the polymer shortening by the hydrolysis](https://figures.academia-assets.com/43362038/figure_006.jpg)

![PLA and PLA-PHB nanocomposite film formulations and their viscosity molecular weight (My). Table 1 (EasyDrop-FM140, KRUSS GmbH, Hamburg, Germany) equipped with a camera and Drop Shape Analysis SW21; DSA1 software was used to test the water contact angle (6°) at room temperature. The contact angle was determined by randomly putting 5 drops of distilled water (~2 wL) with a syringe onto the film surfaces and, after 30 s, the average values of ten measurements for each drop were used. The maximum standard deviation in the water contact angle measurements did not exceed +3% [30]. the final film formulations were expressed taken into account the proportion reported in Table 1. The intrinsic viscosity [yn] of samples was determined to estimate the viscosity molecular weight by means the Mark—Houwink relation:](https://figures.academia-assets.com/43362038/table_001.jpg)