The nitrogen-doped diamond films have been successfully synthesized by using urea as the nitrogen source. Selected-area deposition of diamond nuclei was formed by using a SiO 2 layer as the masking material. Diamond pads, around 9 mm in... more

Industrial port cities are essential components in a society dependant on fossil fuels and low cost energy. In the global move towards a low-carbon society, industrial port cities are emblematic of complex and integrated socio-ecological... more

A new method based on a computer vision and statistical learning system is proposed to estimate the wear level in cutting inserts and to identify the time for its replacement. AISI SAE 1045 and 4140 steel bars of 250 mm of length and 90... more

With the anticipated widespread usage of metal matrix composites (MMCs) in the near future, the machinability of high performance MMCs needs to be understood. This paper reports research results obtained from the grinding of... more

Several global corporations have been severely criticized by different lobbying groups for the impact of their operations on the natural environment and on the local communities. Because corporate operations cannot be studied in isolation... more

SIMAP is the abbreviated name for the Intelligent System for Predictive Maintenance. It is a software application addressed to the diagnosis in real-time of industrial processes. It takes into account the information coming in real-time... more

Plasma-substrate interactions in diamond synthesis via microwave plasma-assisted chemical vapor deposition (CVD) are an important issue in CVD reactor optimization. The hot spot formation observed during single-crystal diamond synthesis... more

Recent improvements in machine and spindle designs have led to the increased use of high-speed machining (HSM) in the manufacture of discrete parts, especially in the aerospace industry . HSM seeks to increase depth of cut, and the... more

In this work, optimisation of process parameters used for gas metal arc welding of dissimilar metal joint involving duplex stainless steel (DSS) to grade ASTM/UNS S32205 and weathering steel CORTEN-A to grade ASTM A242 is attempted. Such... more

This paper presents a model for the three-dimensional (3D) dynamic response of endmills while considering the actual fluted cross-sectional geometry and pretwisted shape of the tools. The model is solved using the spectral-Tchebychev (ST)... more

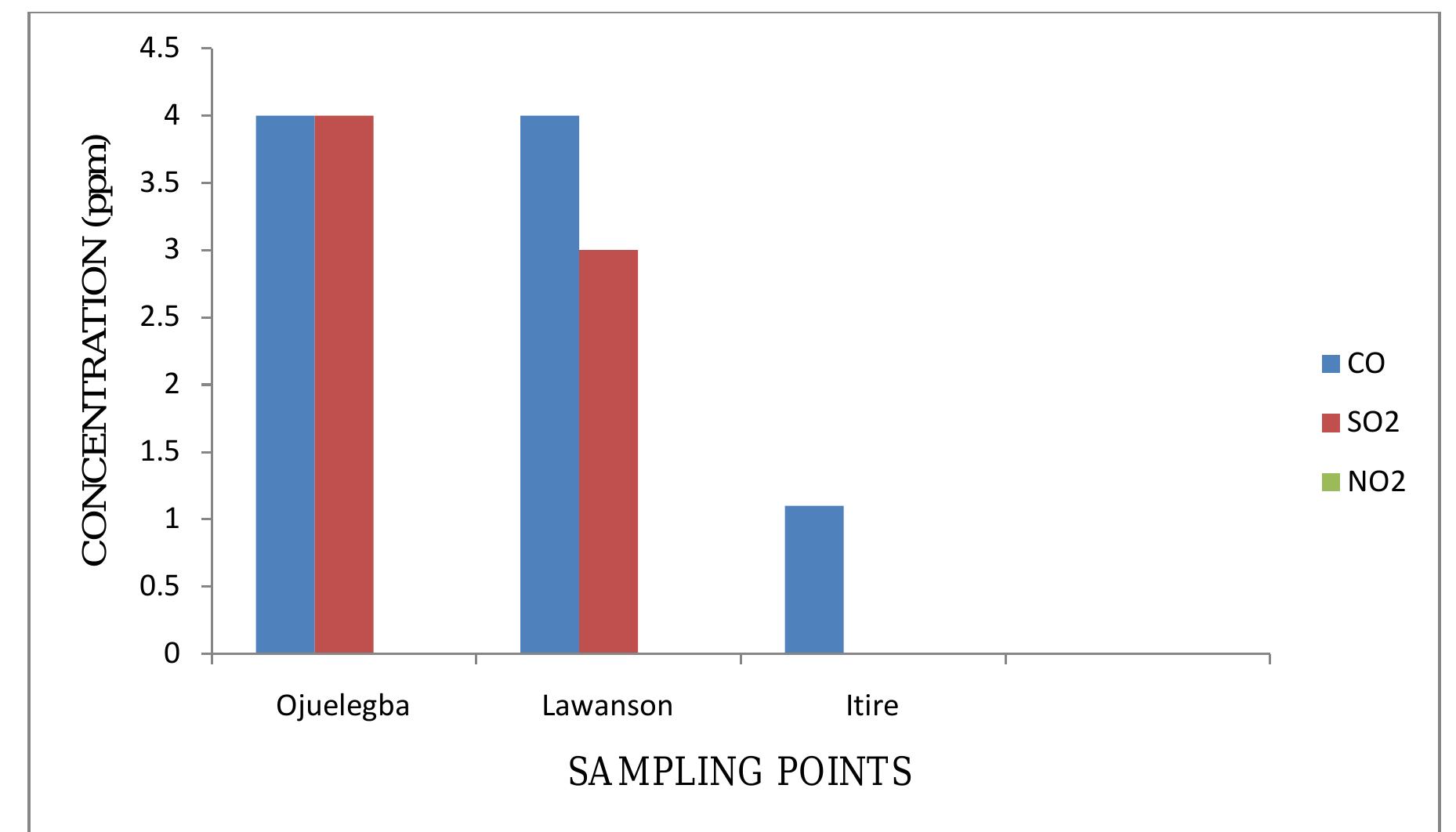

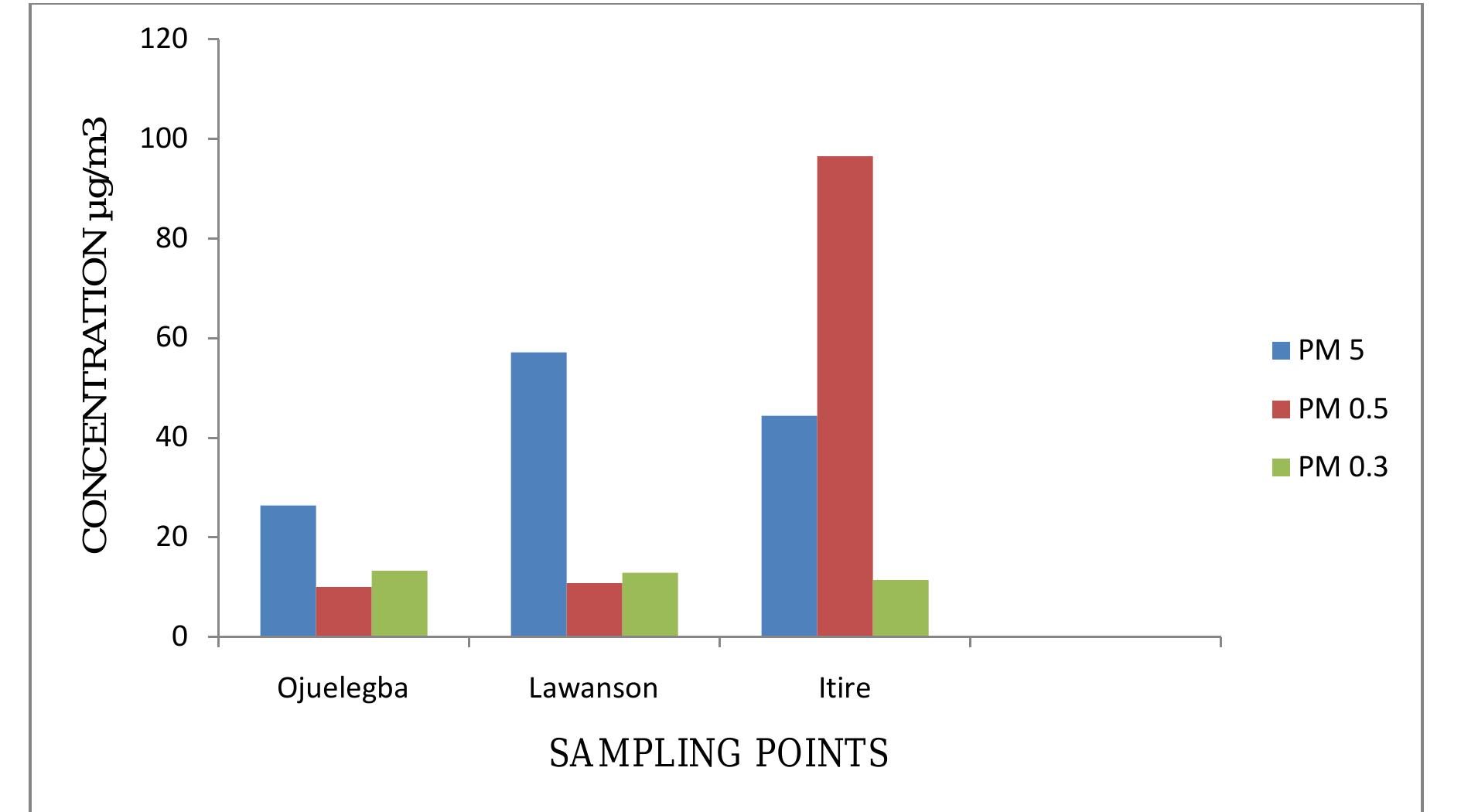

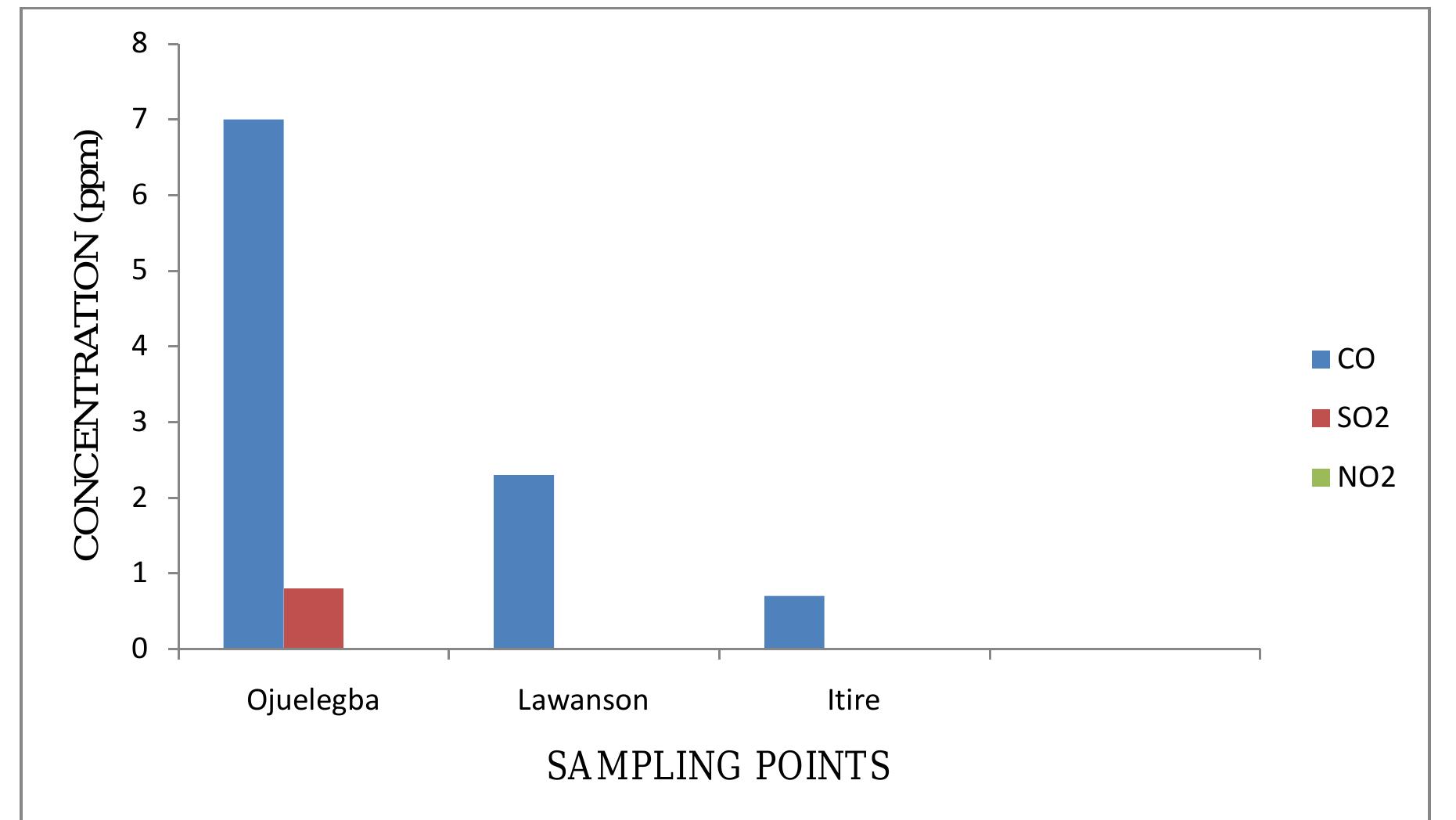

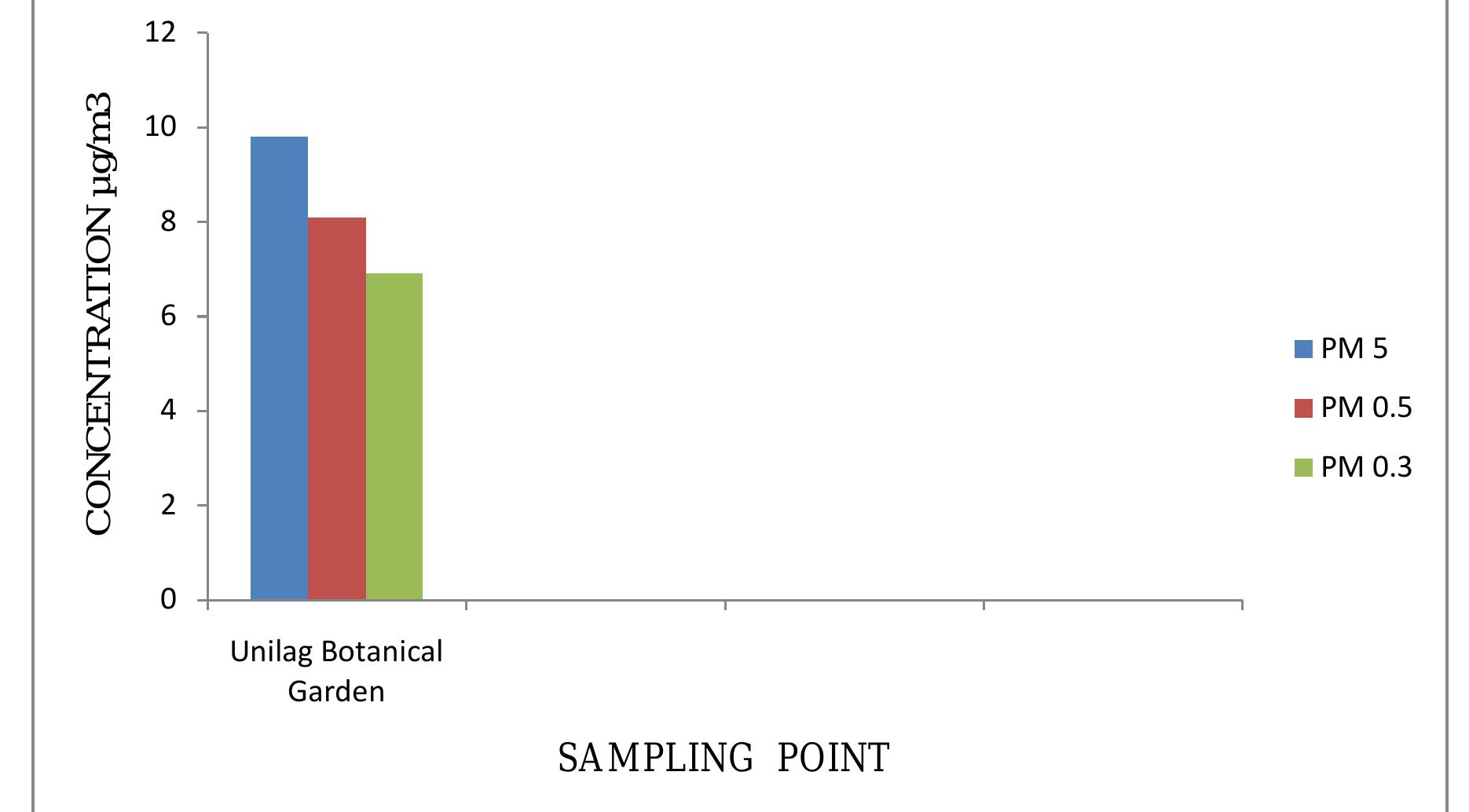

Air pollution is one of the major environmental problems confronting developing countries like Nigeria. Lagos, a state in Nigeria is endowed with many commercial and industrial activities. These activities as well as vehicular emissions,... more

Temperature measurements are employed for research into the mechanics of grinding and for process monitoring. Temperature measurement in grinding presents a number of challenges particularly in High-Efficiency Deep Grinding (HEDG). High... more

In this paper we present the second generation receptance coupling substructure analysis (RCSA) method, which is used to predict the tool point response for high-speed machining applications. This method divides the spindle-holder-tool... more

3-D printing has entered the consumer market because of recent radical price declines. Consumers can save substantial money by offsetting purchases with DIY pre-designed 3-D printed products. However, even more value can be obtained with... more

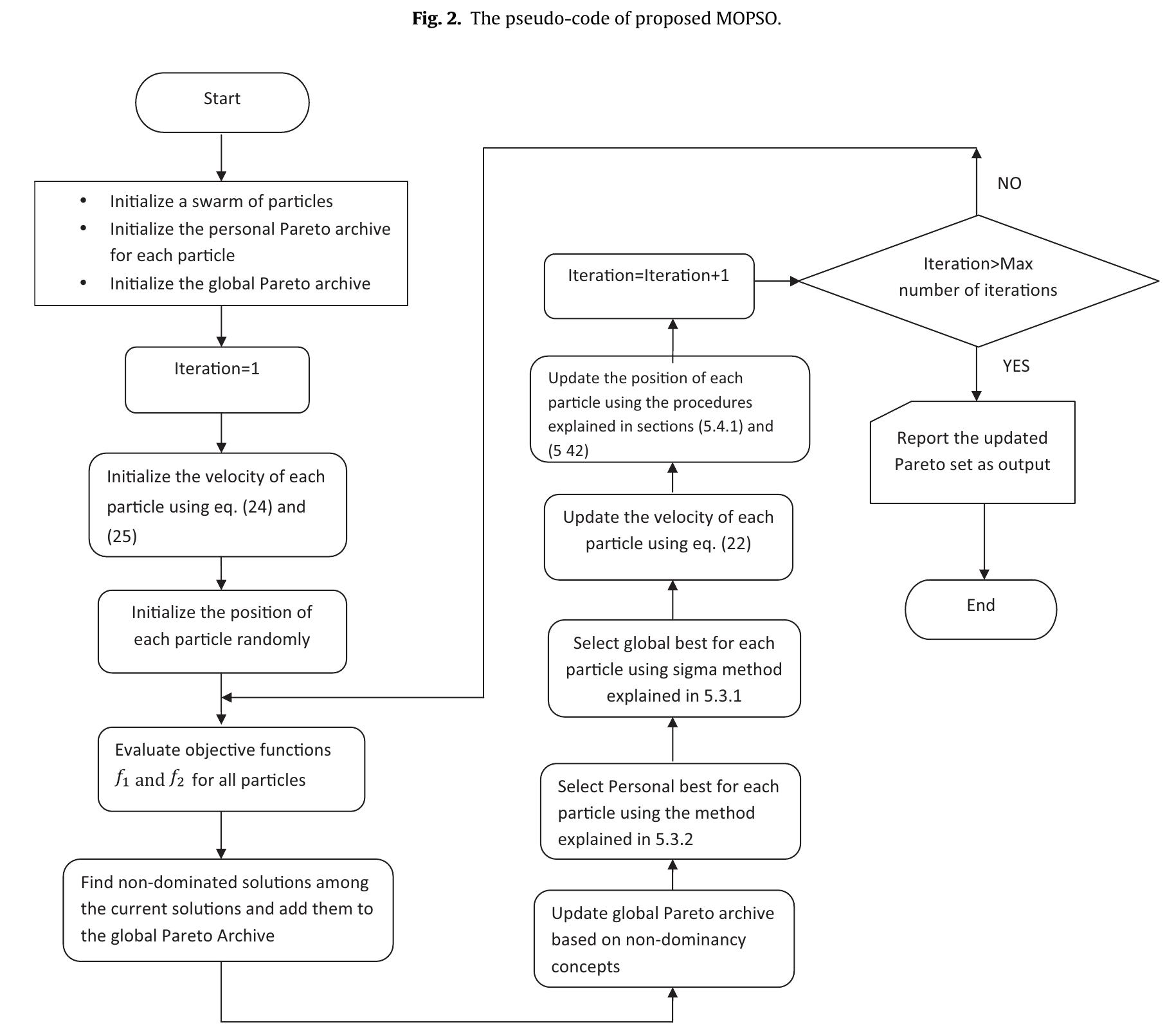

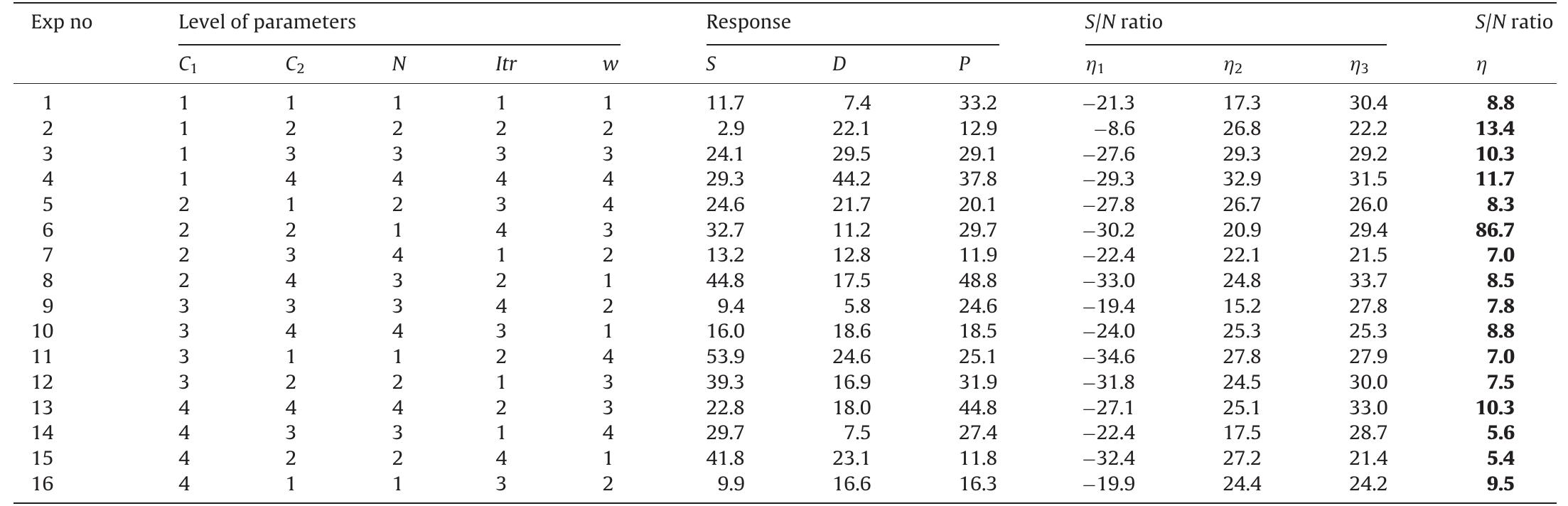

This paper addresses a highly challenging scheduling problem faced in multi-head beam-type surface mounting devices (SMD) machines. An integrated mathematical model is formulated aiming to balance workloads over multiple heads as well as... more

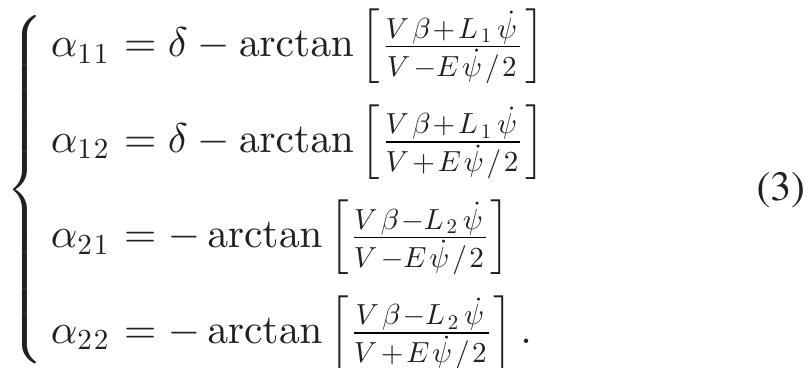

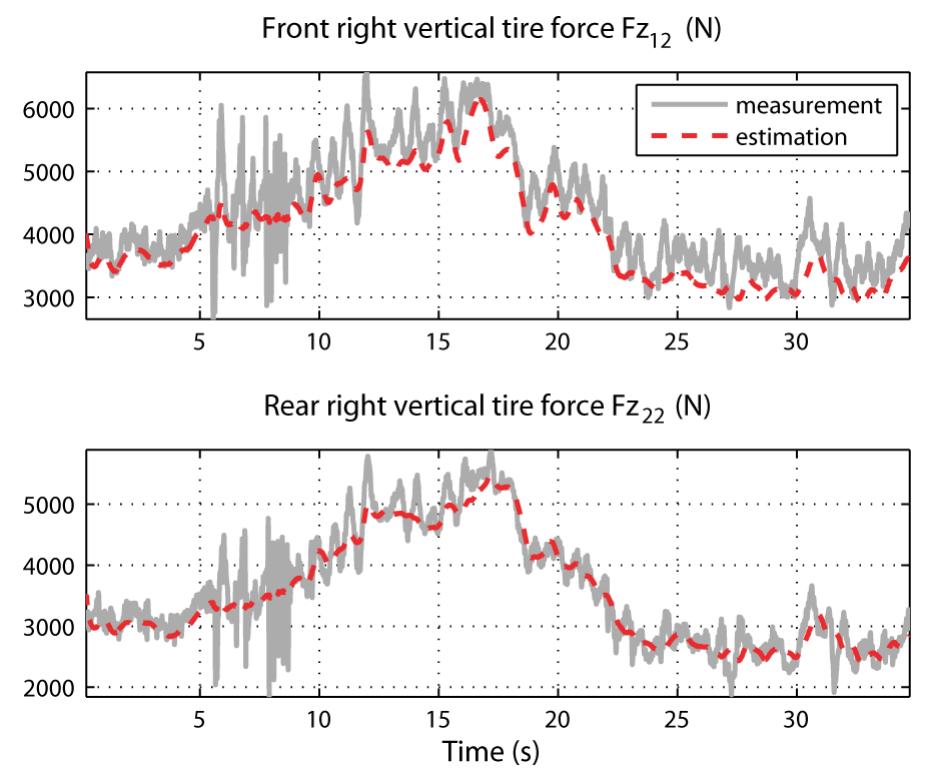

The principal concerns in driving safety with standard vehicles or cybercars are understanding and preventing risky situations. A close examination of accident data reveals that losing control of the vehicle is the main reason for most... more

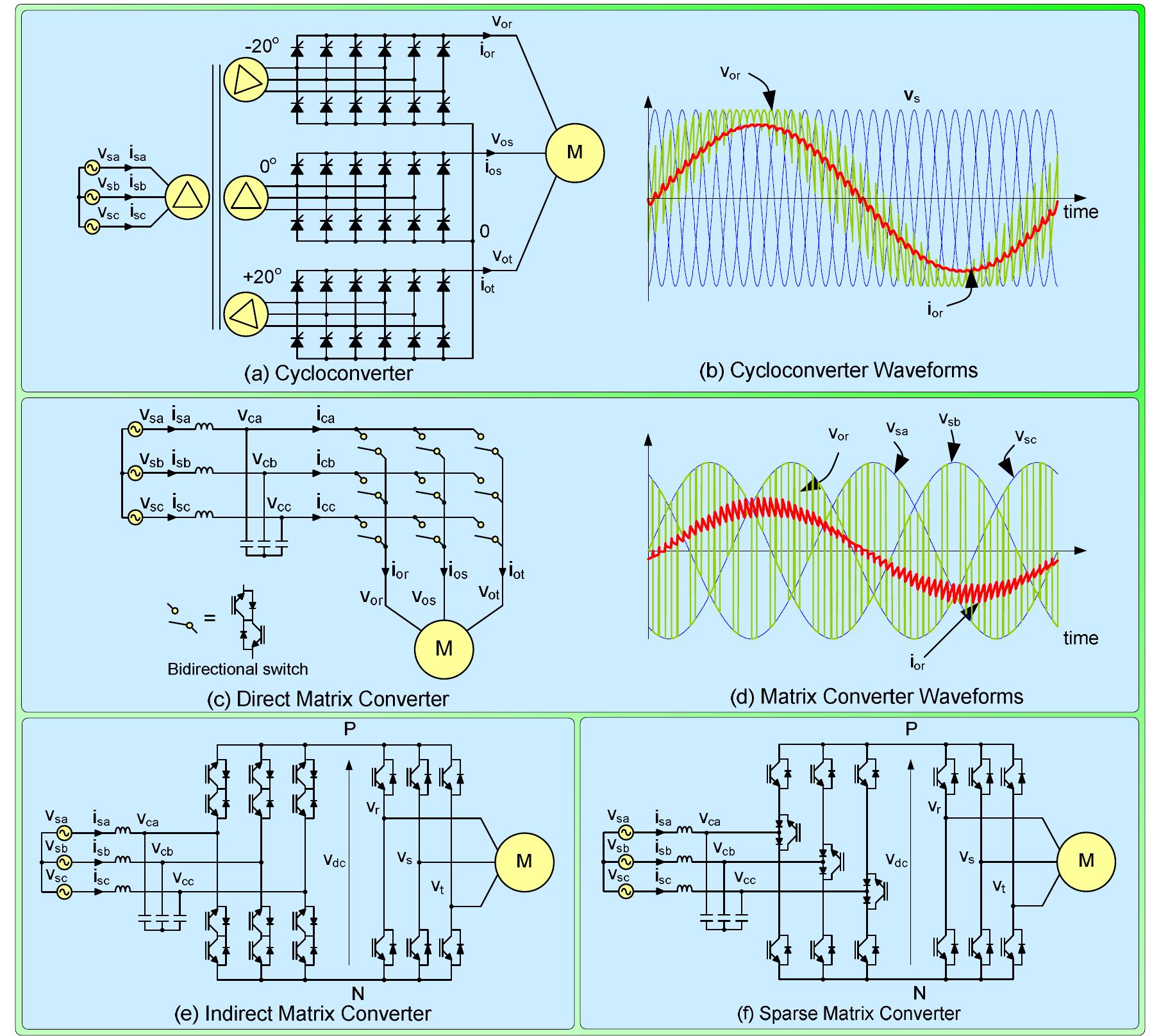

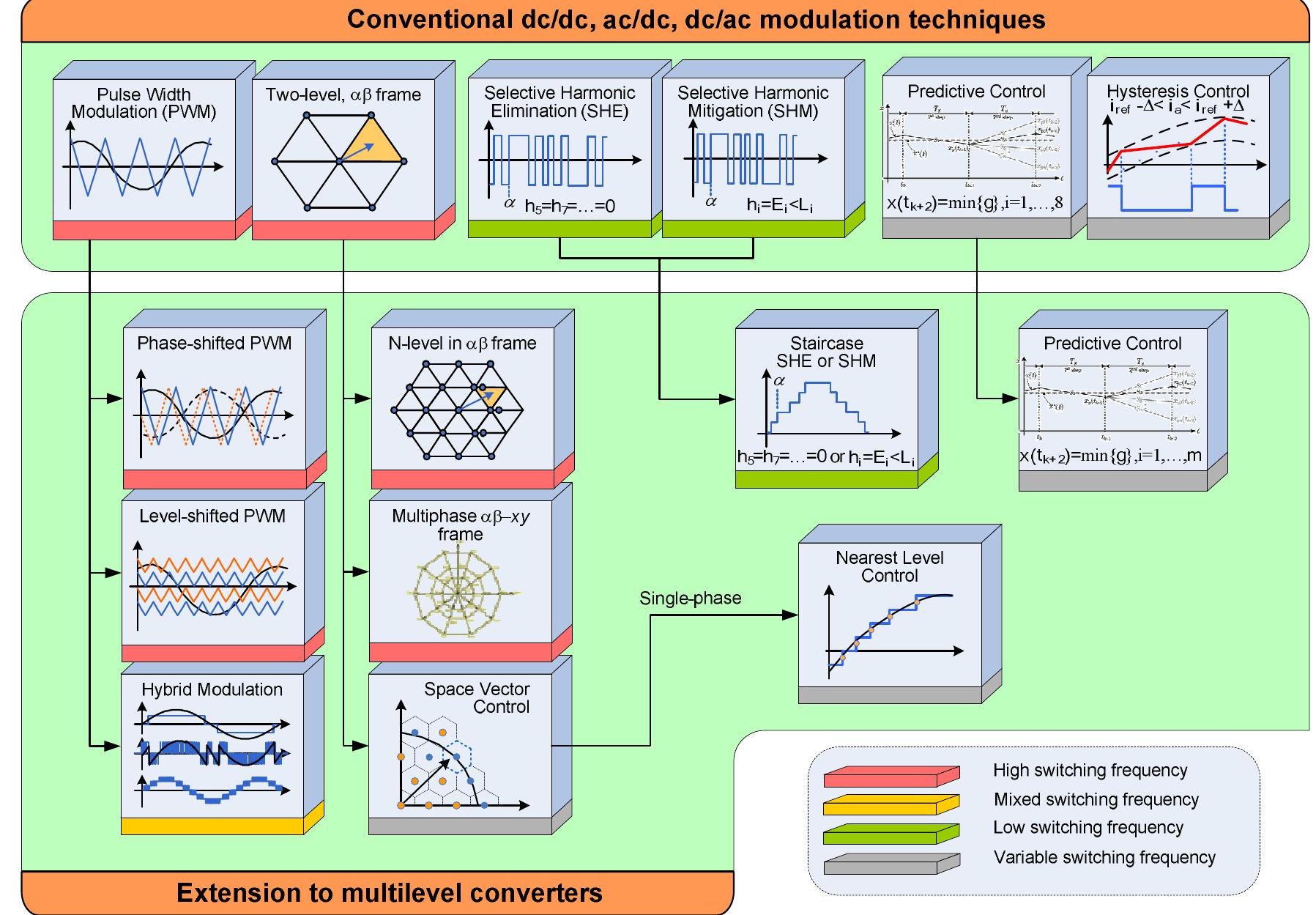

Power electronic converter-fed high performance AC drives belong to high-tech industry and are one of main factors for energy saving and productivity growth. This paper reviews present state and trends in development of key parts of... more

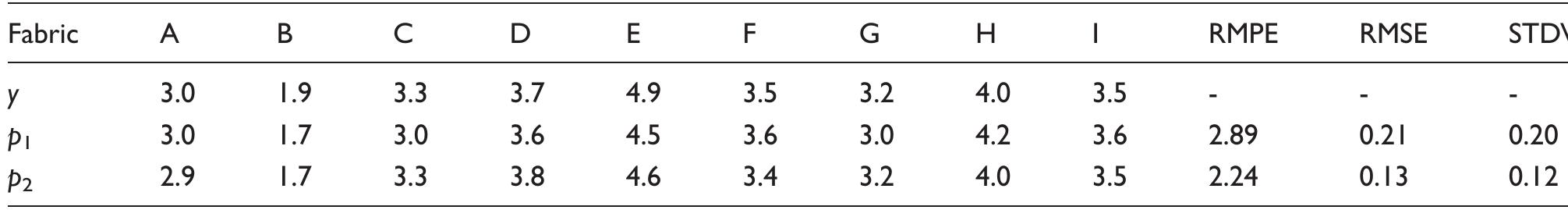

This paper aims to predict the hand values (HVs) and total hand values (THVs) of functional fabrics by applying the fuzzy logic model (FLM) and artificial neural network (ANN) model. Functional fabrics were evaluated by trained panels... more

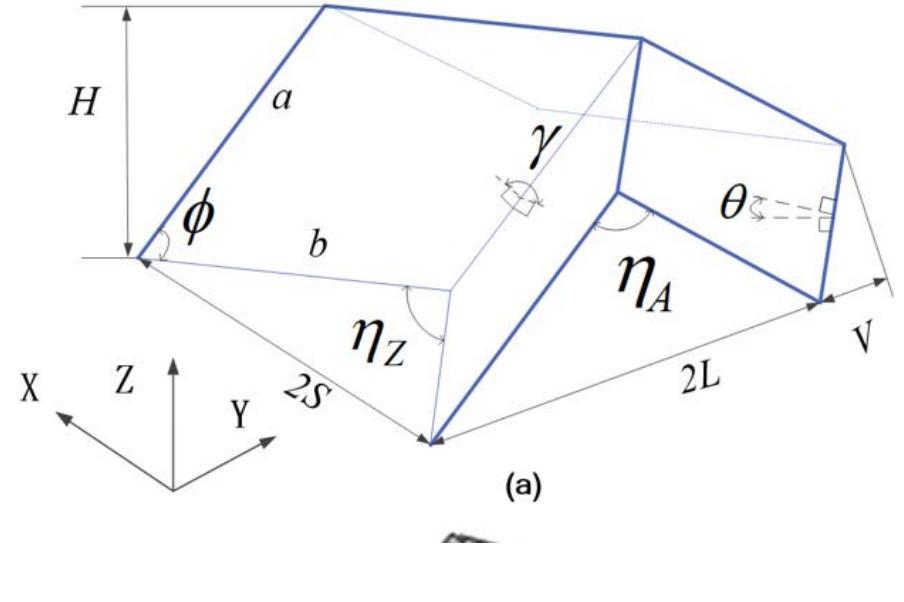

Miura-ori patterned sheets have been recognized as efficient energy absorption devices that can serve as the core of sandwich structures or a layer of metamaterials. In this paper, first, the geometric characteristics of a Miura-ori... more

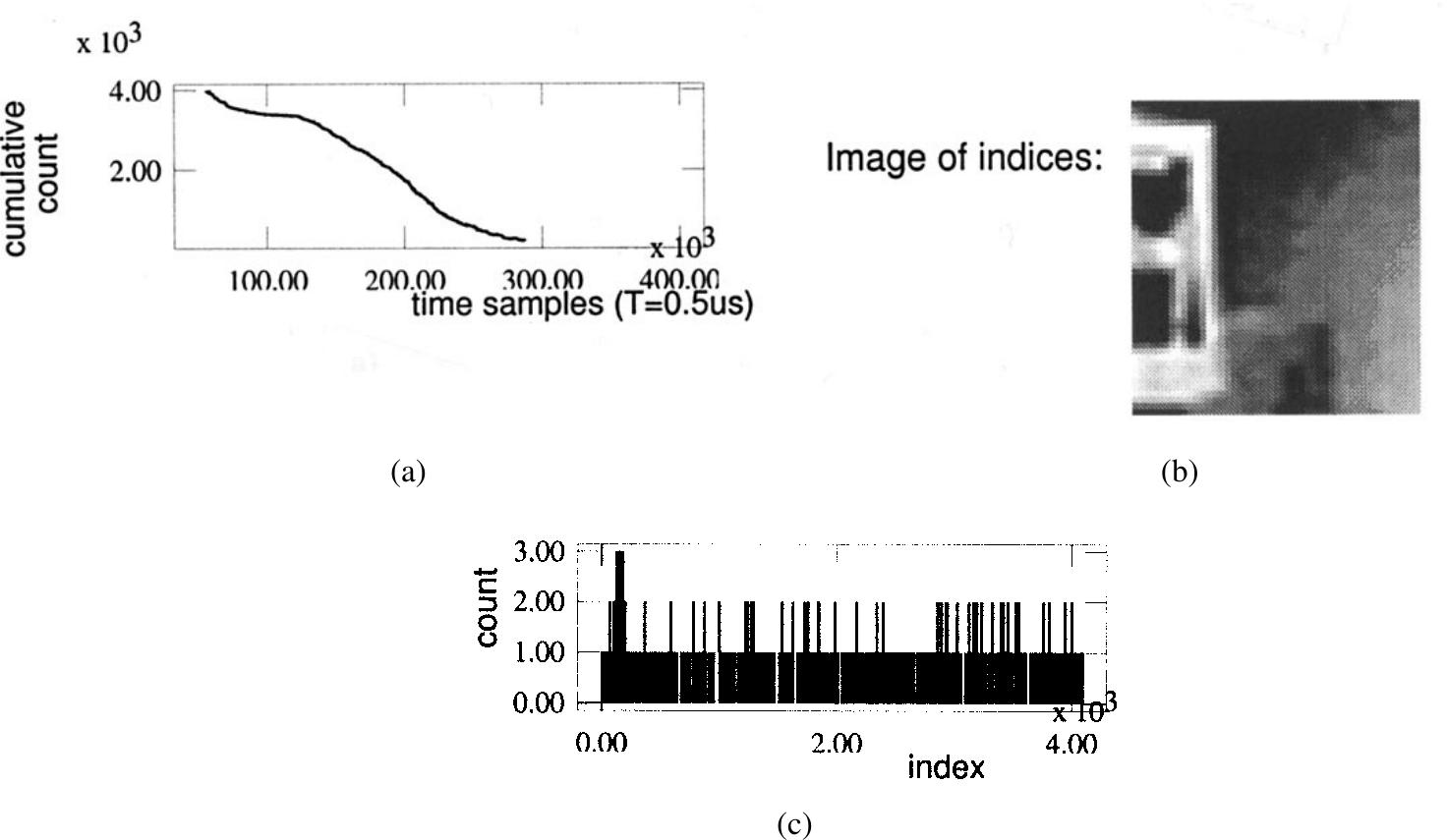

This paper presents a new intensity-to-time processing paradigm suitable for very large scale integration (VLSI) computational sensor implementation of global operations over sensed images. Global image quantities usually describe images... more

Dynamic decision problems constrained by time are of highly-interested in many aspects of real life. This paper proposes a new concept called the Dynamic Interval-valued Neutrosophic Set (DIVNS) for such the dynamic decision-making... more

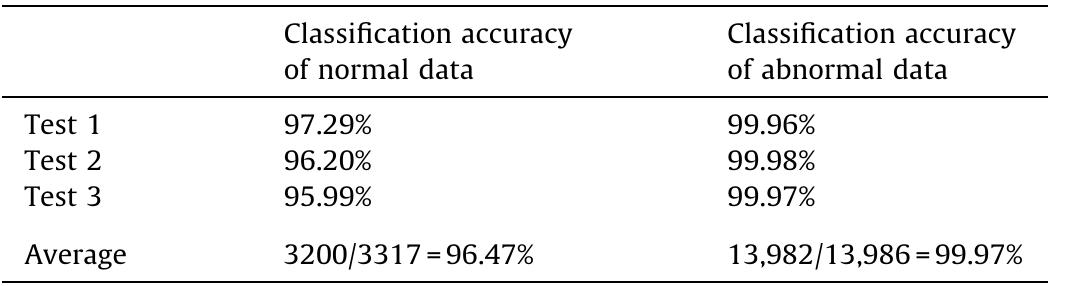

Generation of particle defects in semiconductor manufacturing is inevitable, but it has to be minimized to enhance IC yield. There are various causes for the generation of particle defects in different semiconductor manufacturing... more

The development of the Toyota Production System (TPS) based on principles of lean technology has especially impressed numerous manufacturers around the world. It attaches remarkable importance to reducing and then eliminating waste and... more

Cotton is not the answer to meet the rapidly growing demand for textile fibers. Wood-based regenerated cellulose fibers are an attractive alternative. Since wood is a candidate to replace fossil raw materials in so many applications of... more

In the context of an increasing commitment to water efficiency in the EU policy, a different approach for eco-efficiency assessment in the agricultural sector, at the meso level, was applied to the Monte Novo irrigation perimeter, located... more

The aim of the study was to improve the efficiency of the double roller cotton gin in terms of ginning output and energy consumption. Therefore a spike cylinder–type gin feeder with the concept of single locking of cotton bolls was... more

The shape of a differential thermal analysis (DTA) curve depends on the sample and the reference, the heating or cooling rates used in the experiment as also the thermal resistance to heat¯ow from the heat source to the cell containing... more

The purpose of this work was to develop a model for estimating 'dry' and 'wet' thermal resistance of bedding during use. The model takes into account proportions of the body covered by different bedding arrangements, and the effects of an... more

Ductile iron can acquire enhanced thermal and mechanical properties from austempering heat treatment. The present study aims to identify the function of different cutting parameters affecting machinability and to quantify its effects.... more

Experimental performance evaluation of heat pump-based steam supply system T Kaida, I Sakuraba, K Hashimoto et al. -Fluid-Structure interaction analysis and performance evaluation of a membrane blade M. Saeedi, R. Wüchner and K.-U.... more

Increasing attention is being devoted to the airborne emissions resulting from a variety of manufacturing processes because of health, safety, and environmental concerns. In this two-part paper, a model is presented for the amount of... more

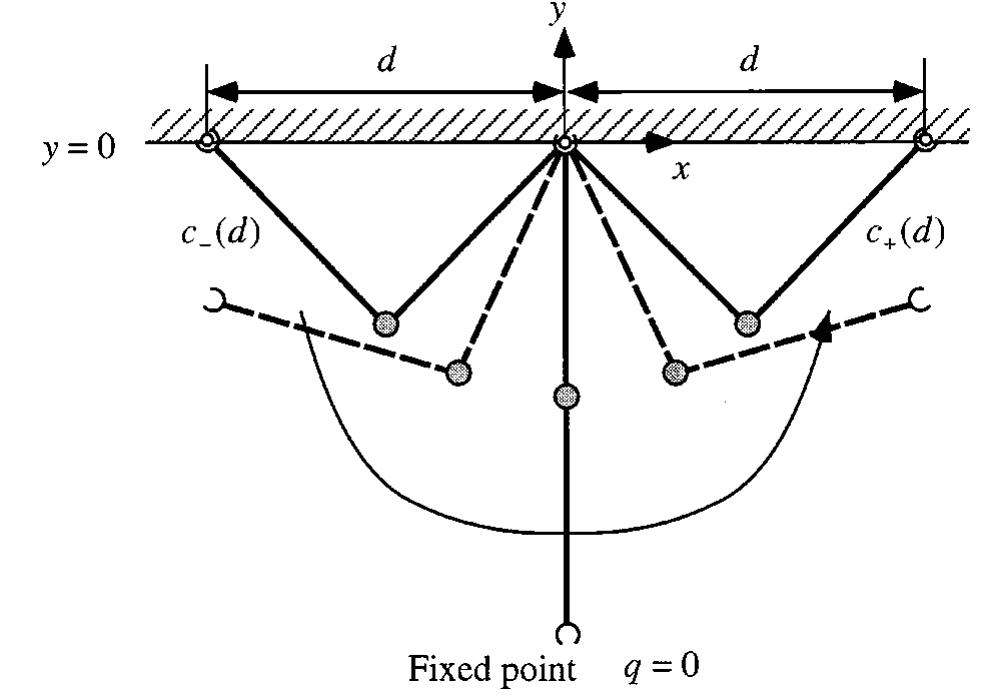

We report on our empirical studies of a new controller for a two-link brachiating robot. Motivated by the pendulum-like motion of an ape's brachiation, we encode this task as the output of a "target dynamical system." Numerical... more

The exposure of H-terminated nanocrystalline diamond (NCD) to ultraviolet (UV) light in air and at room temperature modifies the features of the diamond surface, in terms of wettability, electrical conductivity and chemical reactivity.... more

Low-power laser scanning techniques provide a powerful tool for a diverse range of automatic inspection tasks. They are more suitable for high component feed rates, less sensitive to changes in ambient lighting and their output requires... more

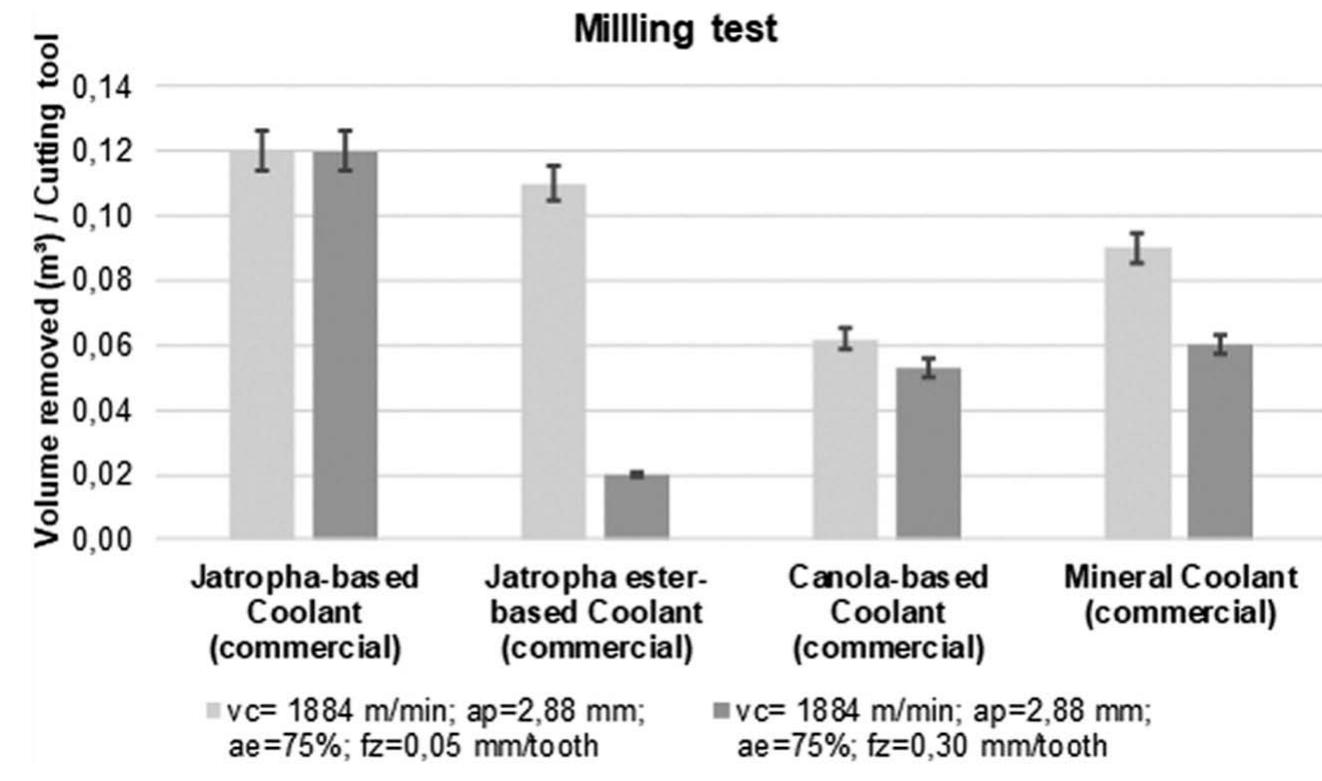

Cutting fluids are an inherent part of the modern manufacturing system. With the increase in the industrialization and development of new materials and processes, there has been a need for developing new cutting fluids with superior... more

The global cement industry produces over four billion tonnes annually. In recent years, the quest for increasing energy efficiency has led this industry to test and use "waste" materials as alternative fuels (AF). The objective of this... more

With the use of a case study methodology, the socially responsible enterprise La Feuille d'Erable, based in north-west France, was analysed based upon the framework proposed by Boons and Ludeke-Freund (2013). Within an overarching... more

Part I of this paper contained a technological description and economic evaluation of a large-scale highend CDW recycling plant in the Lisbon Metropolitan area. It concludes that economic viability is likely under the operating conditions... more

A globally convergent adaptive control scheme for robot motion control with the following features is proposed. First, the adaptation law possesses enhanced robustness with respect to noisy velocity measurements. Second, the controller... more

As greenhouse gas emissions are a key driver of climate change, sources of CO 2 must be mitigated, particularly from carbon-intensive sectors, like power production. Natural gas provides an increasingly large percentage of electricity;... more

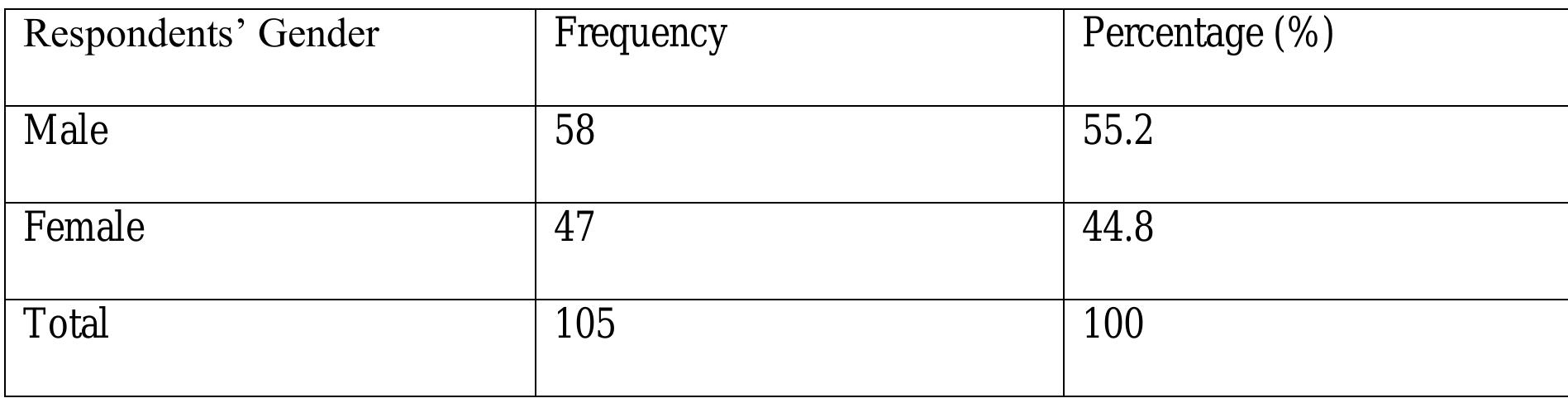

Today, it can be maintained that the customer is a ‘king’ as he will buy only the products that satisfy his needs and wants. The companies of today are facing new challenges: global business and local operation, standardization, and... more

Much textual engineering knowledge is captured in tables, particularly in spreadsheets and in documents such as equipment manuals. To leverage the benefits of artificial intelligence, industry must find ways to extract the data and... more

![Fig. 2. Fibre optic technique; (a) system configuration; (b) output signal; [20]. Fig. 1b illustrates the use of a phototransistor (4) that records infrared radiation from the grinding zone through a hole (2) made in the wheel. The current generated by the phototransistor is proportional to the intensity of infrared radiation. The signal is conditioned by an amplifier (6) and sent to a recording device (7). This method provides an almost noise free signal but has problems. The method only Recent research in fibre optic sensing has made it possible to develop a new temperature measurement device based on fibre Bragg technique. The change in the sensing grating due to the heat causes variation of the wavelength of the reflected light. Wavelength division multiplexer (WDM), coupler and two gratings method, and thin film](https://figures.academia-assets.com/43714503/figure_002.jpg)

![Fig. 5. Single-pole thermocouples inserted in a grinding wheel [12]. 3.2.2.2. Insertion in a workpiece. In the single-pole configuration, constantan is used to form a J-type Grindable double-pole thermocouples as shown in Fig. 4 can be formed at the workpiece surface and overcome some of the problems of the conventional double-pole thermo- couple. The approach to assemble a grindable double-pole thermocouple is similar to the assembly of a grindable single-pole thermocouple as described below. The increased number of layers involved in the double-pole arrangement](https://figures.academia-assets.com/43714503/figure_005.jpg)

![Fig. 11. Effect of thermocouple width on temperature signal. where b-grinding width, /, contact length; F, tangential grinding force and v, is the linear speed of the grinding Grinding forces were measured using a Kistler 3-axis dynamometer. Table speed was measured using an acoustic emission sensor that recorded the AE signal from the grinding contact. Measured temperatures were validated with the help of a thermal model [8].](https://figures.academia-assets.com/43714503/figure_010.jpg)

![Fig. 15. Temperature readings varying thermocouple thickness. where /¢ is the heat convection factor for the fluid. In dry and burnout conditions, the fluid convection factor is effectively zero. As reported in [8,9,16,17] values of fluid convection for water-based fluid vary broadly from 0 to 290,000 W/m?K depending on the effectiveness of fluid delivery and the type of fluid. Fluid convection factor can also be estimated very approximately assuming steady Heat convection into the fluid estimated from Eq. 10 is much lower than possible with a fluid surface on the wheel since the fluid contact in practice is turbulent rather than static. This increases the rate of heat transfer. However, the](https://figures.academia-assets.com/43714503/figure_015.jpg)

![Fig. 21. Source of noise in recorded signal. (a) Environmental noise due to machinery [21], (b) Coolant application looping workpiece to table.](https://figures.academia-assets.com/43714503/figure_020.jpg)

![Fig. 2. Two-component assembly. The component responses are coupled through a rigid connection to give the assembly receptance(s) Based on the coordinates defined in Fig. 2, the equations to determine the assembly direct receptances, G,,(@) and Gy,(@), and the assembly cross receptances, G,,(@) and Gy,(@), can be written as a function of the substructure receptances as shown in Eqs. (3)-(6), where rigid connections have been applied [32].](https://figures.academia-assets.com/41397706/figure_001.jpg)

![As noted, in order to populate the substructure receptance ma- trices, we apply measurement and modeling. Common modeling options include closed-form expressions for uniform Euler- Bernoulli beams [33] and finite element solutions (which can in- corporate the more accurate Timoshenko beam model [34]). We consider both approaches in this study. As a convenience to the reader, the relevant analytical formulas and finite element Timosh- enko stiffness and mass matrices are included in the Appendix. Fig. 3 Example standard holder for spindle-holder base sub- assembly receptance identification (dimensions provided in Table 1). Hammer impacts are completed at locations 3, 3b, and 3c to identify the required direct and cross receptances](https://figures.academia-assets.com/41397706/figure_002.jpg)

![Fig. 15 Measured and predicted H,, results for four different overhang lengths (132.1, 106.7, 94.0, and 76.2 mm). The over- hang length for each of the four results is identified. Predic- tions were completed using the flexible/damped connection (connection parameters are provided in Table 8) Table 8 Connection parameters for shrink fit holder cas¢e study Appendix: Beam Receptance Modeling Bishop and Johnson [33] showed that the displacement and rotation-to-force and moment receptances for uniform Euler- Bernoulli beams could be represented by simple closed-form ex- pressions. For a cylindrical free-free beam with coordinates j and k identified at each end, the frequency-dependent direct and cross receptances are given by:](https://figures.academia-assets.com/41397706/figure_016.jpg)

![where A is the cross-sectional area, / is the section length, r, is the radius of gyration, and ¢ is a shear deformation parameter given by) is the shear modulus (v is Poisson’s ratio) and k’ is the shear coefficient which depends on the cross-section shape and v [40]. The stiffness matrix (which included damping) was:](https://figures.academia-assets.com/41397706/figure_019.jpg)

![The Lig orthogonal array. The values of (m)j;,;. Table 12 Table 10 minimized, diversification metric and number of Pareto solutions are maximized. Taguchi design uses S/N ratio instead of mean value to interpret the trial results data into a value for the evaluation char- acteristic in the optimum setting analysis, because S/N ratio can reflect both mean and variation of the performance characteristics. In this paper, Taguchi parameter design with the utility concept, which has been introduced by Kumar et al. [40]), is applied. Here S is minimized, D and the number of Pareto solutions are maximized. Hence, “smaller the better type” characteristic for S and “larger the better type” characteristic for D and the number of Pareto solutions have been selected. The S/N ratio associated with the responses, S, D and the numbers of Pareto solutions (P) are given as:](https://figures.academia-assets.com/47547400/table_008.jpg)

![Figure 1. Classification of the power converter applications The roots of power electronics go back to 1901 when P. C. Hewitt invented glass-bulb mercury-arc rectifier [1]. However, the present era of semiconductor power electronics started with the commercially introduced by General Electric (GE) silicon controlled rectifier (SCR), popularly called thyristor, in 1958. Next, the development continued in new semiconductor structures, materials, fabrication, etc. bringing on the market many new devices with higher power ratings and improved characteristics. Today among most common power electronic devices are: power metal oxide semiconductor field effect transistor (MOSFET) and insulated gate bipolar transistors (IGBT), and in very high power range the integrated gate-commutated thyristors (IGCT) jError! No se encuentra el origen de la referencia.]. Also, integrated intelligent power modules (IPM) are available. Today very promising, opening new era of high voltage, high frequency, and high-temperature technology are semiconductor devices based on wide-band gap silicon carbide (SiC) material.[3]. The new power semiconductor devices have always triggered the development of new converter topologies. At the beginning it started with diode and thyristor line commutated converters and continued with modern forced commutated converters controlled via pulse width modulation (PWM) methods. The list of application of power electronics is too long to list them in all. Therefore, in Figure 1, a classification of the typical applications of power electronic converters from low to high power group is given. This paper presents an overview of power converter-fed high performance AC drives in three basic parts: power converter topologies. POWER CONVERTER TOPOLOGIES IV. 1. Voltage Source Converters](https://figures.academia-assets.com/44817266/figure_001.jpg)

![Several Torque Control (TC) methods have been developed in the last 40 years. Not all of them have found wide industrial applications. Therefore, we present only the most popular strategies used commercially and some of future trends. Existing TC methods can be classified in different ways [72][73]. In this paper, the TC methods are presented in two main groups: linear and nonlinear controllers. The discussed generic TC methods are presented for the induction motor drives; however, they can be easily expanded for control of permanent magnet synchronous motors (PMSM) with sinusoidal electromotor force (EMF) and currents.](https://figures.academia-assets.com/44817266/figure_006.jpg)

![controller is applied and its output produces an increment in the torque angle, Ady (see vector diagram in Figure 9) [80][81]. Assuming that the rotor and flux magnitudes are approximately equal, the torque is controlled only by changing the torque angle, dw, which corresponds o the increment of the stator flux vector AW;. The commanded stator flux vector is calculated by addition of the estimated flux position ys; and change of he torque angle Ady. Its value is compared with the estimated flux and the stator flux error AW, is used directly for calculation of VSI switching states in he FVM block [82][83]. Thanks to internal stator flux loop used for calculation of AW, in flux pulse width modulator, the flux PI controller of Figure 8 is eliminated.](https://figures.academia-assets.com/44817266/figure_009.jpg)

![As reported in the works by G. Papafotiou et. al. (see in [86][87]) by using a long output horizon predictive DTC, the average switching frequency, and as consequence also inverter switching losses, has been reduced 16,5% with respect to the classical DTC used by ABB while maintaining the same control quality of the motor torque, magnitude of stator flux and 3-level inverter’s neutral point voltage. This illustrates a very high improvement potential of the MPC.](https://figures.academia-assets.com/44817266/figure_012.jpg)

![Figure 15. Flux vector observer based on measured Vs, |,, Qn with compensation signal calculated from measured /, and estimated /,’ stator current vectors [85][95] between the two models is defined by design of the PI controller which generates compensation voltage Ucomp. Finally, in Figure 15, an flux vector observer based on measured stator voltage Vs, current I,, and mechanical speed Q, with compensation signal calculated from measured |, and estimated |,’ stator current vectors is shown. In this observer the motor model is fed with current vector estimated from the stator and rotor flux. The measured stator current is delivered only to Pl controller for calculation the compensation voltage Ucomp. Therefore, the model can be easily used for testing and investigation. With mechanical motion sensor it operates well at zero speed [85][95].](https://figures.academia-assets.com/44817266/figure_015.jpg)

![Fig. 1. Classification of fault detection and diagnosis methods (adapted from Zhang and Jiang [5]).](https://figures.academia-assets.com/87456885/figure_001.jpg)

![Fig. 4 Turning operation with fluid stream application While it is convenient to discuss a mean drop size, an atomiza- tion process produces a wide range of drop sizes. This is due to the random nature of the atomization process, resulting from one or more of the following: i) numerous small satellite droplets are produced in addition to the large droplets, ii) multiple modes of disintegration can simultaneously exist within an atomization pro- cess, iii) cutting fluids are heterogeneous mixtures (rather than homogeneous solutions) with varying physical properties, and iv) small oil droplets may be stripped from the emulsion rather than being produced by a classical atomization process [11]. The mist generation portion of the model uses a lognormal distribution, which is characterized by a geometric mean, D, , and a geometric standard deviation, o, , henceforth referred to simply as the mean and standard deviation, respectively, to describe the distribution of droplets that are generated. The determination of these quantities, as well as the corresponding mass concentration, will be discussed in the following sections. At this point it should be noted that the equations used to model the atomization process are expressed in](https://figures.academia-assets.com/47932670/figure_004.jpg)

![Table 1 Cutting fluid properties The effect of cutting fluid type, or composition, on the atomi- zation mechanism can also be explored using the model. The properties for the three different cutting fluids [20,21] under con- sideration are listed in Table 1. Using Eq. (6) with a nozzle diam- eter of 6.35 mm, workpiece diameter of 104.8 mm, and fluid properties, the predicted mean droplet diameter as of spindle speed and cutting speed are determined. The the listed a function results are presented in Fig. 10. The figure reveals that the fluid significantly impact the mean droplet diameter. type can](https://figures.academia-assets.com/47932670/table_001.jpg)

![Fig. 11. Effect of the wire feed rate on: (a) the crack length: (b) the dilution ratio: and (c) the C and Mn contents in the weld metal. Another effect of wire feed rate, which is thought to play a considerable role in decreasing the cracking susceptibility, is the change in the bead dimensions and microstructure, which are associated with the change in the wire feed rate. It is observed from the macroscopic observations of the welded beads that the greater the wire feed rate, the wider is the weld bead, whilst the weld depth remains constant, Fig. 12. This interpreta- dilution ratio decreases with a decrease in the wire feed rate. as illustrated in Fig. II(b), this greatly affecting the resulting chemical composition of the weld metal. The wire used is characterised by depletion in the carbon content combined with enrichment in the Mn content. As the decrease in the dilution ratio means an increase in the wire content in the bead, then the bead composition will also be characterised by depletion in carbon and enrichment in manganese. This is supported by chemical analysis of the welded beads. Fig. 11(c) indicating that increasing the wire feed rate results in increased ‘%C and decreased ‘%Mn in the weld metal. Previous investigations [4,6.10] have reported that the Mn content in the welded bead tends to decrease its cracking susceptibility.](https://figures.academia-assets.com/44322751/figure_010.jpg)

![Fig. 2. A two-link brachiating robot. Fig. 1. Brachiation of a gibbon: a picture taken from [2].](https://figures.academia-assets.com/44303107/figure_001.jpg)

![Fig. 7. Numerical approximationw = NC ). Target dynamics controller, r..., is tuned according to this mapping, A, that is designed to locate neutral orbits originating in the ceiling. In general, as discussed in Section I, we can expect no closed-form expression for \ or \~!, and we compute an estimate \ using a standard numerical scalar root finding method (i.e., the “false position” or “secant” method) whose convergence properties are well known [27]. We plot in Fig. 7 a particular instance of \ for the case where the robot parameters are shown in the table in Fig. 4. w is tuned according to this mapping. We will use these parameter values throughout the sequel for the sake of comparison between this and subsequent figures.](https://figures.academia-assets.com/44303107/figure_006.jpg)

![Figure 3. Lubrication vs. cooling property of cutting fluids?” turning, milling, and grinding in which more cooling action is required. High cutting speed increases the temperature during machining which affects the viscosity of the cutting fluid and as such a lubricant having a higher viscosity index (mineral oils with naphthenic base) is preferred to a lubricant having a lower viscosity index (petroleum base mineral oil). A proper cutting fluid selection program is important with regard to machining operation as well as the material of the workpiece.°°°°! Although cutting fluids have immensely improved productivity, they have many disadvantages.!”177! These have negative effect on human and environment.!°* °173-75] Shockingly, a huge 12 mn ton waste cutting fluid is](https://figures.academia-assets.com/86592833/figure_001.jpg)

![increasing the AIL content in MJO but with PIL as an additive in MJO, the cutting force increases gradually. MJO retains high lubricating efficiency compared to synthetic ester due to its strong interaction with the metallic surface. MJO provides outstanding lubrication owing to the long carbon chain,?!°?°?24] MJO-AIL 10% provided the lowest specific cutting energy, followed by MJO-PIL 1%, MJO AIL 1%, MJO, SE = MJO-AIL1% = MJO-PIL 5%, and highest with MJO-PIL 10%.This trend is due to the fact that high viscosity reduces the flow and the rate of heat transfer of the lubricant. The optimum value is needed in order to get the least specific cutting energy. In terms of reducing temperature MJO-AIL 10%, MJO-PIL1%, and MJO-PIL 5% gave less temperature than MJO and synthetic ester. MJO-AIL 1%, MJO-AIL 5%, and MJO-PIL 5% gave temperature more than MJO and synthetic ester. Ionic liquids, even in minute quantity, have shown to enhance the performance of oils significantly. Low specific cutting energy attained with their addition indicates their viability and feasibility to be used as an additive to oils used in machining operations. LUO WAL SLAL UIAILICLEL Witli iviyrX, iNCaL Tid, piVvVier itdot Wedl scar diameter, which was 17% less wear scar diameter with the synthetic ester. AIL presents 8% less wear than a synthetic ester. MJO 10% AIL presented 28% less wear scar diameter than neat MJO. It is observed that only a 1% PIL additive is adequate in improving the tribological properties (anti- friction and antiwear) of MJO. MJO PIL 1% reduced wear scar diameter by 36% than MJO. Increasing the amount of ionic liquid in the base oil increase the degree of contact of the lubricant with the surface which enhances the contact of lubricant particles and hence the lubricity. Tapping torque tests gave the highest thrust force with MJO (70.4 N). The thrust forces reduce with more addition of AIL. However, the thrust force was raised slightly upon raising the quantity of PIL. Load carrying capacity increases with an increase in viscosity which in turn depends on the length of the carbon chain. An adequate amount of viscosity helped to lower the amount of thrust force required in the tapping torque test. MJO AIL 10% and MJO PIL 1% reduce the thrust force significantly as compared to MJO and synthetic ester. The polarity in the lubricants provides effective lubrication due to the formation of a tribological film on the surface of the metal, which protects the metal surface. AIL and PIL are potentially good additives that can enhance the performance of base oils remarkably. Figure 19 shows wear scar diameter obtained with different ionic fluids?! pace](https://figures.academia-assets.com/86592833/figure_019.jpg)